Actuation system and clutch device for a motor vehicle

A control system and clutch device technology, applied to mechanical drive clutches, non-mechanical drive clutches, motor vehicles, etc., can solve the problems of increased wear and tear of the moment of inertia, and achieve the effect of saving structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

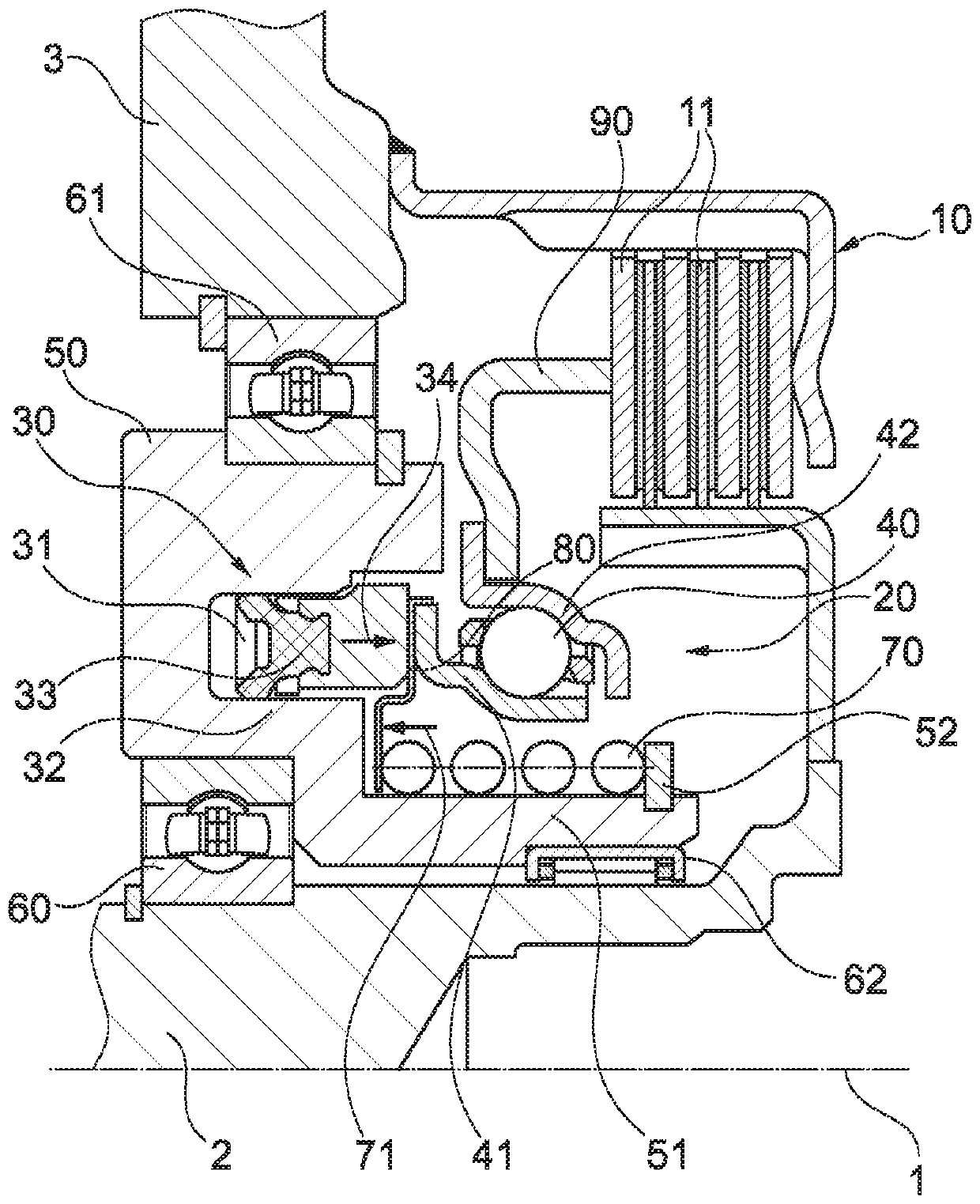

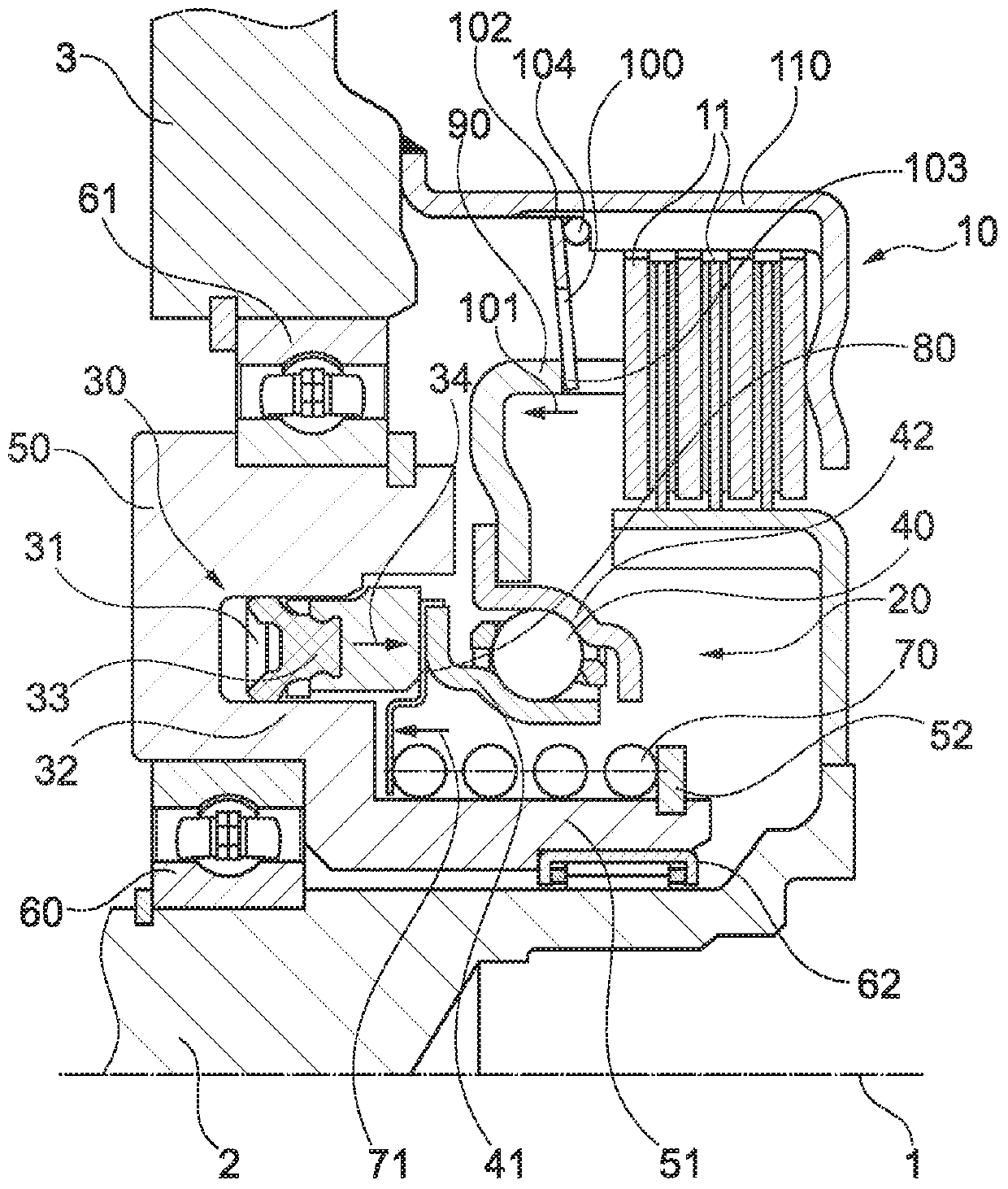

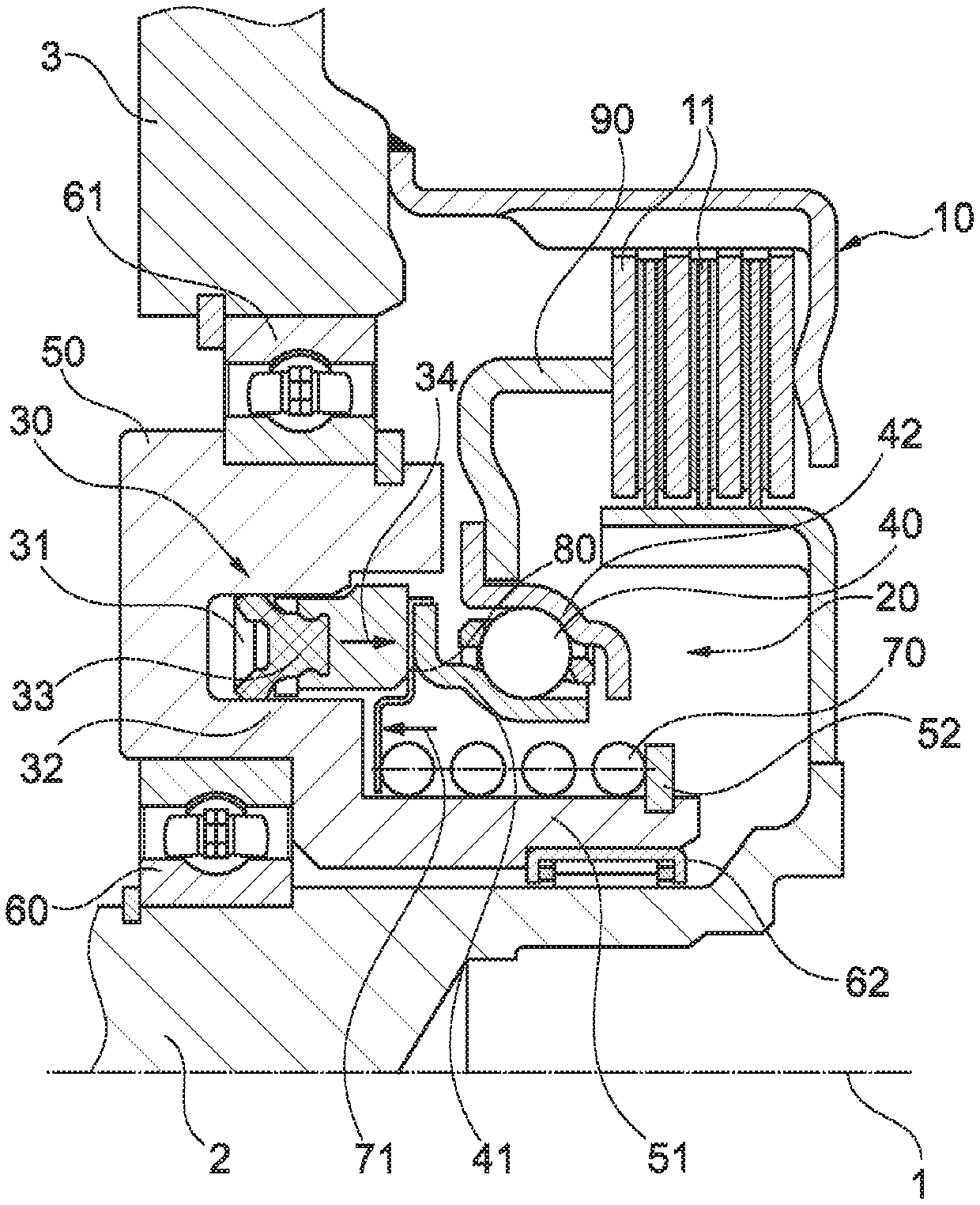

[0031] exist figure 1 A clutch device according to the invention of a simpler construction type is shown in , while in figure 2 A clutch arrangement according to the invention with an additional spring arrangement can be seen in . That is, in figure 1 The clutch device shown in is only supplemented with an additional spring device in the figure 2 shown in .

[0032] Firstly, the general structure of the clutch device according to the invention and the actuation system according to the invention is explained on the basis of two figures.

[0033] The actuation system 20 according to the invention and the clutch device 10 actuated thereby are arranged on a common axis of rotation 1 . The actuation system 20 comprises a piston-cylinder unit 30 , the piston 31 of which is displaceable substantially parallel to the axis of rotation 1 in a cylinder 32 , which is formed by a housing 50 . As a result, the piston 31 can exert an axial force in the acting direction 34 via the actu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com