Printing system and method for printing substrates

A printing system and printing template technology, applied in printing, printing machines, printed circuits, etc., can solve the problems of limiting the use of the substrate surface, unable to set other components, and unable to place directional marks, etc., to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

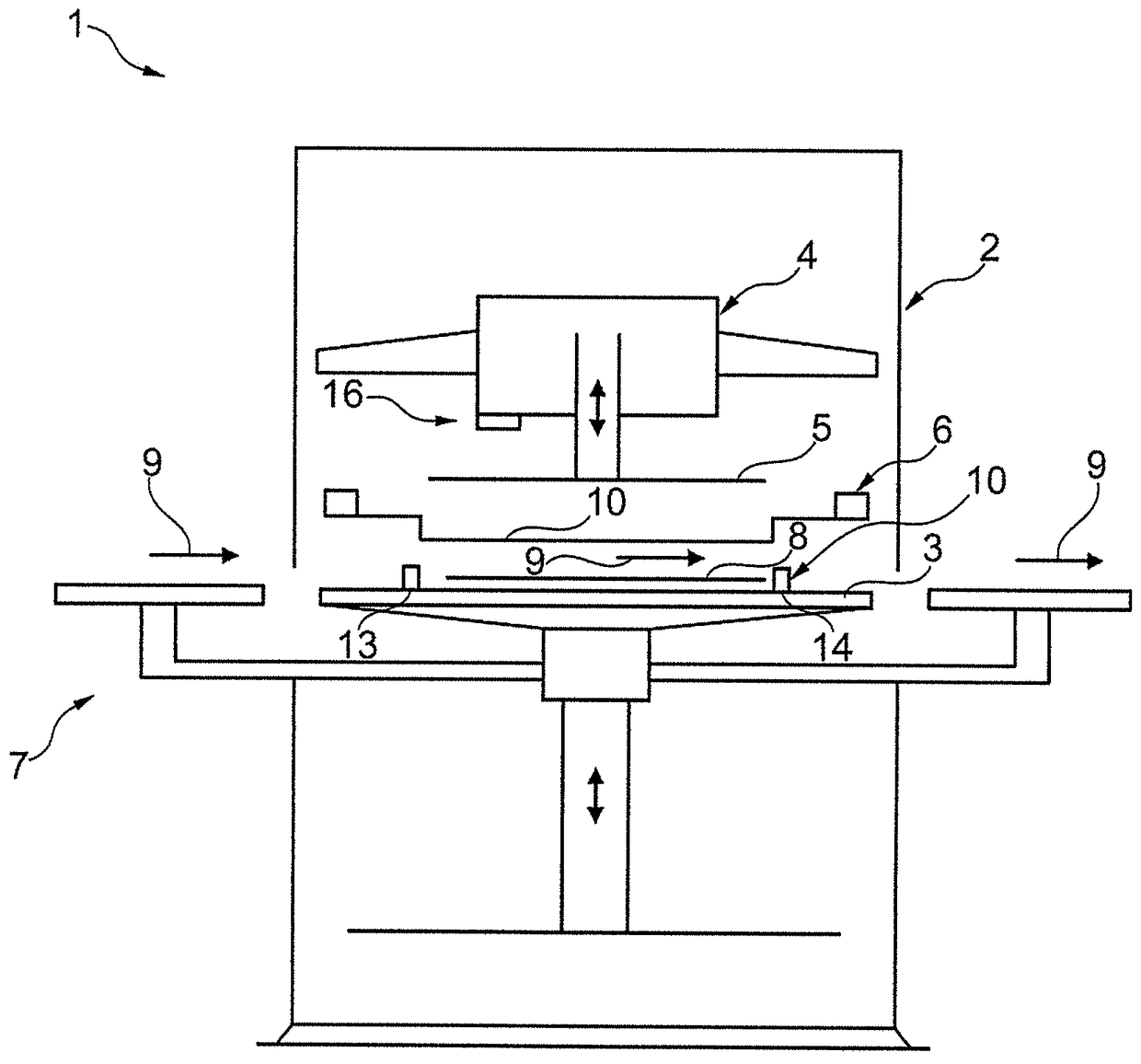

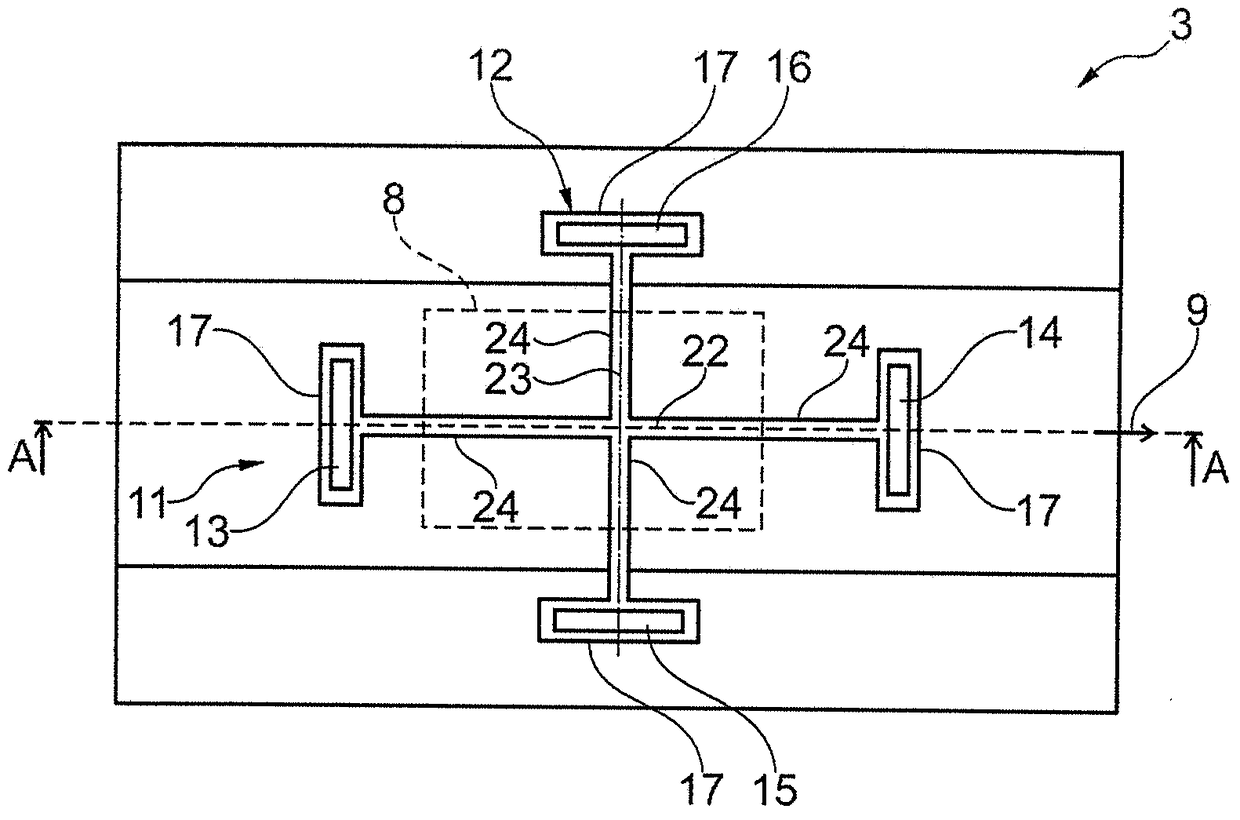

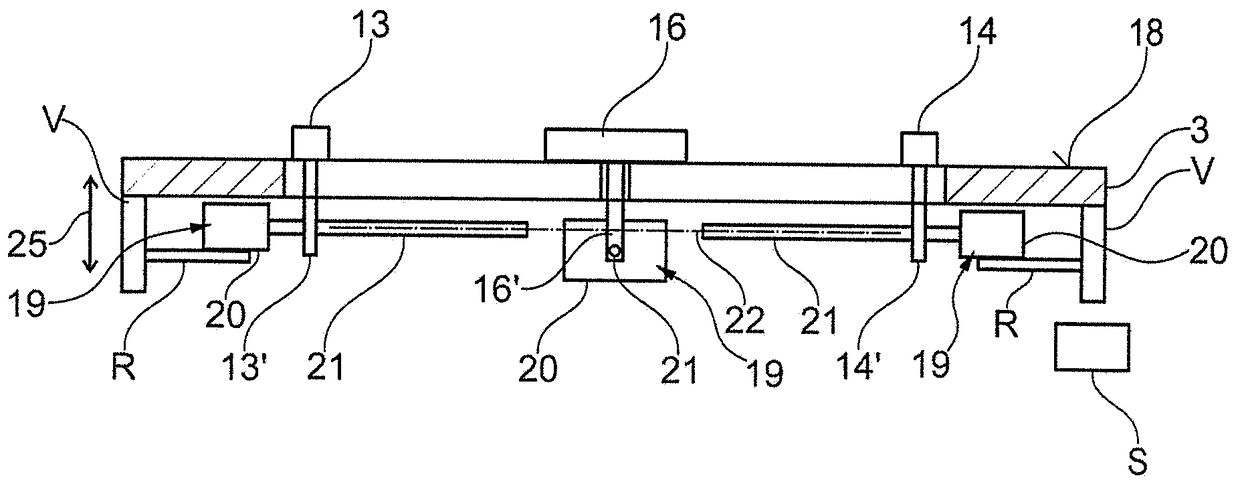

[0020] figure 1 A printing system 1 for printing substrates such as circuit boards, ceramic plates, solar cells, foils etc. is shown in a simplified illustration. The printing system 1 has a printing unit 2 with a printing table 3 and a squeegee arrangement 4 comprising at least one movable squeegee 5 . The printing table 3 and the squeegee 5 are designed in particular to be height-adjustable, as indicated by the double-headed arrow. Furthermore, the printing device 2 also has a printing template 6 arranged between the squeegee 5 and the printing table 3 .

[0021]Furthermore, a transport device 7 is also assigned to the printing unit, which is designed for this purpose to feed the substrate 8 shown here by way of example into the printing unit 2 , to transport it through the printing unit 2 between the stencil 6 and the printing table 3 . , and in turn output from the printing station 3 , as indicated by the arrow 9 indicating the transport direction of the substrate 8 or t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com