Stable speed reducer gear

A reducer, stable technology, applied in belt/chain/gear, mechanical equipment, components with teeth, etc., can solve the problems of poor stability, large contact gap, affecting the reducer, etc., to improve stability, prevent The effect of loosening and ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

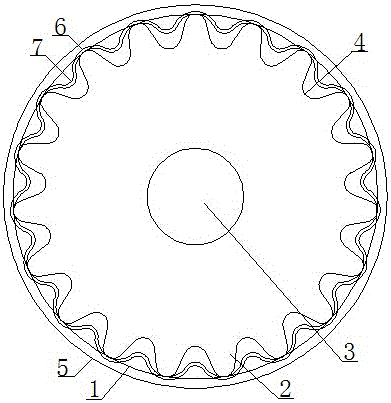

[0013] Such as figure 1 It is a schematic diagram of the structure of the present invention, a stable reducer gear, including a wheel body 1, a tooth body 2 and a shaft hole 3, the tooth body 2 is evenly distributed on the circumference of the wheel body 1, and the shaft hole 3 is located at the center of the wheel body 1 , The wheel body 1 is provided with a gear hole 4, a skirt 5 and a rim 6. The tooth holes 4 are uniformly opened on the circumference of the wheel body 1 and are spaced apart from the tooth body 2 . The skirts 5 are located on both sides of the circumference of the wheel body 1 . The rim 6 is an elastic ring, which is sleeved on the wheel body 1 and embedded between the skirts 5 . The rim 6 is provided with a guide groove 7, and the guide groove 7 is recessed in the tooth hole 4, corresponding to the tooth hole 4 one by one.

[0014] The gear hole 4, the skirt 5 and the rim 6 are set on the wheel body 1, and the gear hole 4 is used to replace the notch bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com