Gear fault positioning system and method

A technology of fault location and positioning method, which is applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problem of not being able to accurately determine the location of gear faults, and achieve the effects of easy grasp and use, accurate algorithms, and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

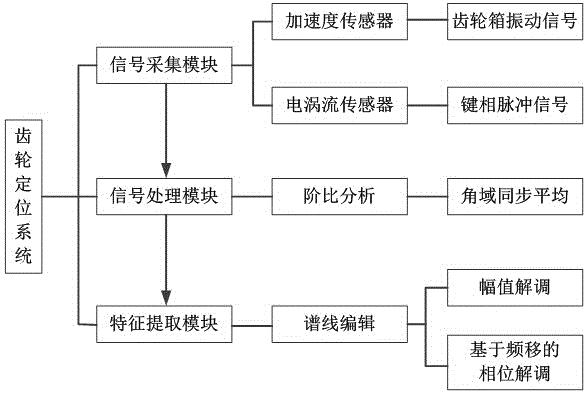

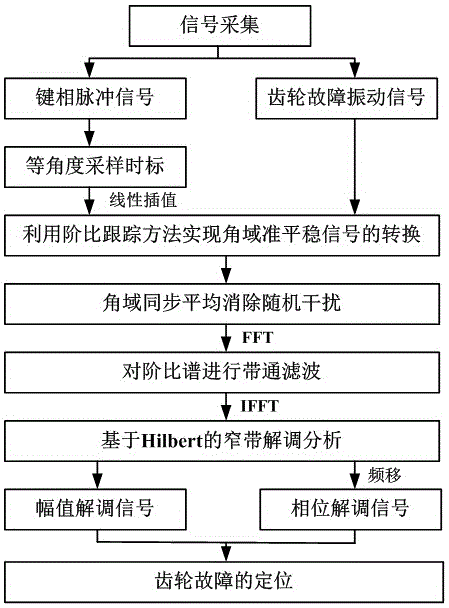

[0042] Embodiment 1: as Figure 1-Figure 2 As shown, a gear fault location system and method include a signal acquisition module, a signal processing module, and a feature extraction module; the signal acquisition module is used to collect vibration signals and key-phase pulse signals from the faulty gearbox through an acceleration sensor and an eddy current sensor. The multi-channel synchronous sampling, the signal processing module uses the order ratio tracking technology to realize the conversion of the quasi-stationary signal in the angle domain, thereby eliminating the frequency ambiguity caused by the fluctuation of the speed and load, and completing the noise reduction of the gear fault vibration signal through the angle domain synchronous average As well as the elimination of random interference, the feature extraction module is used to perform narrow-band demodulation analysis based on frequency shift and spectral line editing on the averaged signal to determine the fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com