A stabilizer bar structure and automobile

A technology for stabilizer bars and automobiles, which is applied in vehicle components, transportation and packaging, interconnection systems, etc., can solve the problems of complex stabilizer bar structures, inability to achieve continuously variable rigidity, etc., to ensure driving safety and ride comfort. , the effect of taking into account the driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

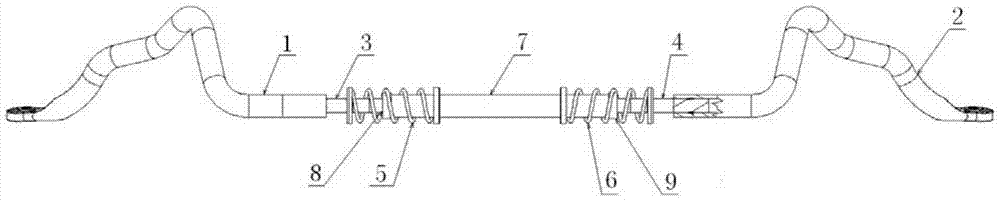

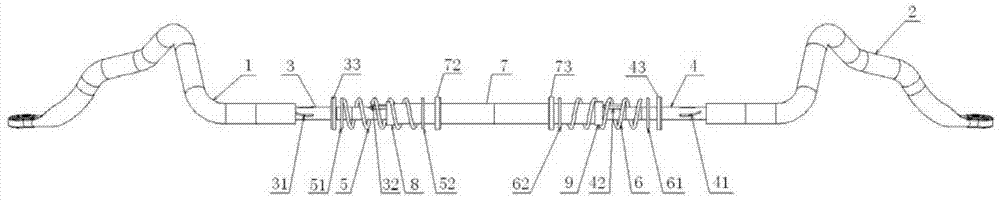

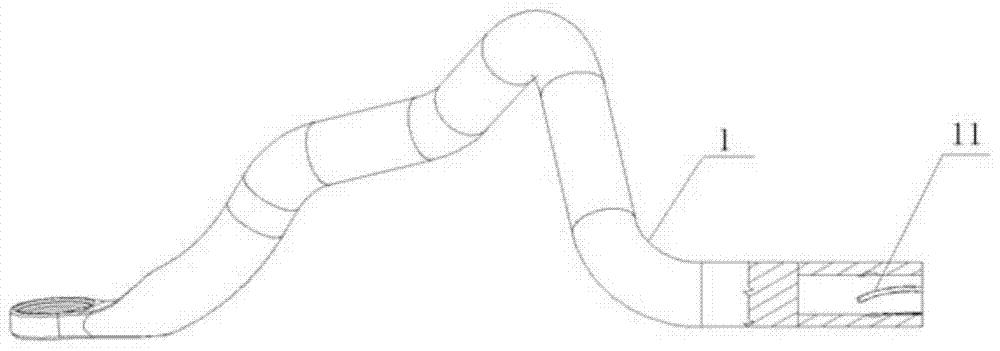

[0032] to combine Figure 1 to Figure 5 As shown, the stabilizer bar structure of the present invention comprises a left mounting rod 1, a right mounting rod 2, a left connecting rod 3, a right connecting rod 4, a left spring 5, a right spring 6 and an intermediate rod 7, the intermediate rod 7 is hollow, and The inner wall of the left end of the middle rod 7 and the inner wall of the right end are symmetrically provided with a left guide groove (not shown) and a right guide groove 71, and at least two first grooves 31 are arranged at intervals along the circumferential direction on the left end of the outer wall of the left connecting rod 3. A groove 31 is arc-shaped and the slope of the left end is greater than that of the right end, and there is a smooth transition between the left end and the right end. A first key 32 is provided on the right end of the outer wall of the left connecting rod 3, and the right end of the left connecting rod 3 is inserted into the middle rod 7 ...

Embodiment 2

[0046] The automobile of the present invention can be provided with the stabilizer bar structure of Embodiment 1, and the stabilizer bar structure can be arranged between the two front wheels of the automobile.

[0047] Further, the stabilizer bar structure can be set in a conventional way, for example, the middle bar of the stabilizer bar structure is connected to the sub-frame of the vehicle, and the left mounting rod 1 and the right mounting rod 2 of the stabilizer bar structure are respectively connected to the connecting rod of the car stabilizer bar.

[0048] The automobile of the present invention can realize continuously variable rigidity by installing the above-mentioned stabilizer bar structure, so that the ride comfort and driving safety of the automobile can be taken into account.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com