A body-mounted locomotive integral fuel tank structure

An integrated fuel tank and load-bearing technology, applied in the direction of locomotives, etc., can solve the problems that the fuel tank cannot participate in the load of the car body, the space utilization rate is not high, and the lightweight design of the car body cannot be satisfied, so as to meet the requirements of lightweight design, convenient installation, The effect of increasing stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

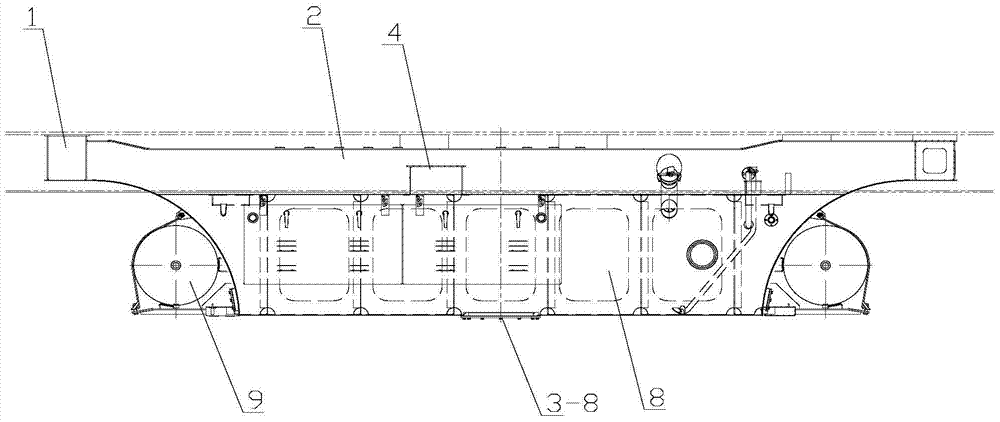

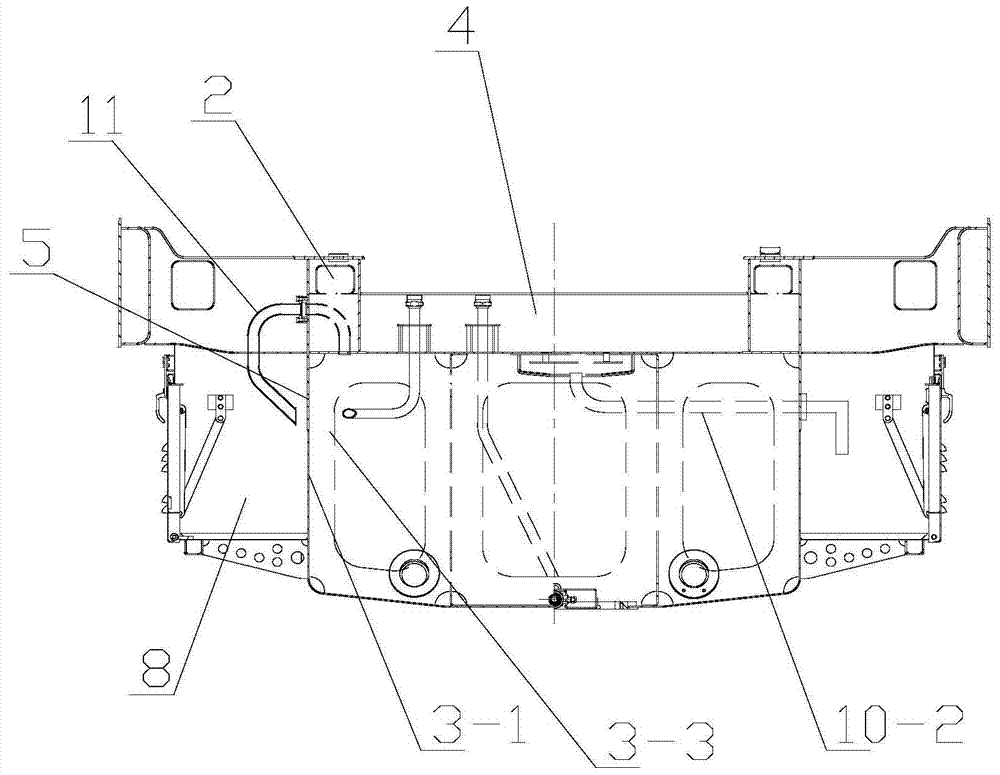

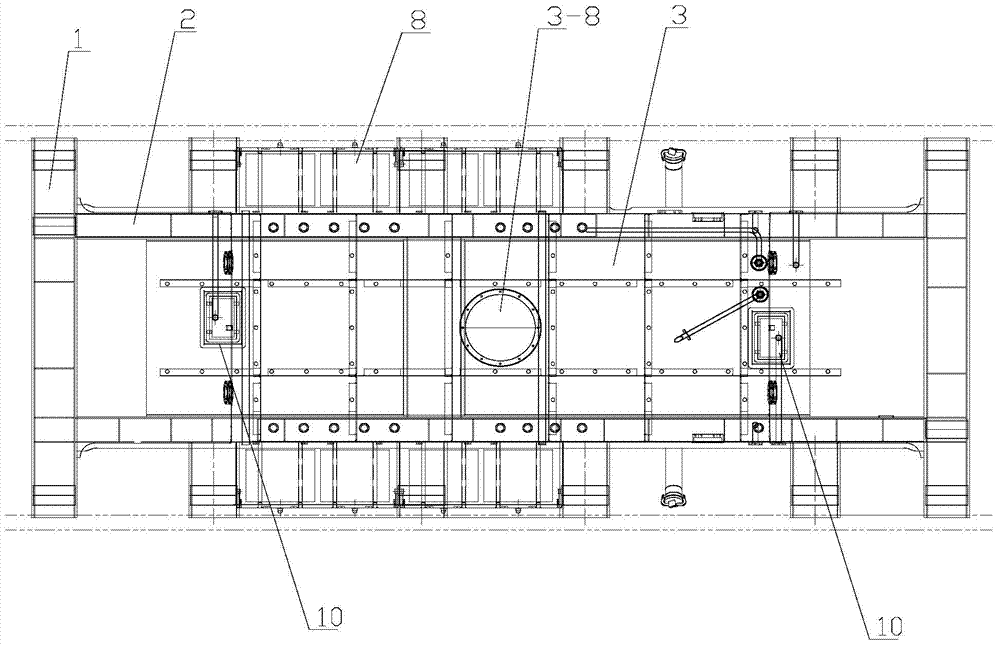

[0042] see Figure 1 to Figure 14 As shown, a body-loaded locomotive integral fuel tank structure includes a crossbeam 1, a longitudinal beam 2 and a fuel tank 3. The crossbeam 1 is connected to two ends of two longitudinal beams 2 arranged in parallel to form an I-shape, and the A reinforcing beam 4 is arranged between the root longitudinal beams 2 . There is an outer plate 5 extending vertically downward on the outer side of the longitudinal beam 2 , the fuel tank 3 is placed between the two longitudinal beams 2 , and both sides of the fuel tank 3 are connected and fixed to the outer plate 5 . The fuel tank 3 is connected and fixed on one half of the outer plate 5 .

[0043] see Figure 4 to Figure 6 , the inside of the longitudinal beam 2 is provided with a group of air ducts 6 for the positive pressure ventilation of the diesel engine room, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com