A fully automatic high-efficiency cloth inspection machine

A cloth inspection machine, fully automatic technology, applied in the inspection of textile materials, textiles and papermaking, etc., can solve the problem of poor use effect of winding and unwinding and cloth inspection machines, low quality of winding and unwinding, poor continuous operation ability, etc. problems, to achieve continuous and stable cloth inspection work, easy disassembly, assembly, maintenance and replacement, and labor-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

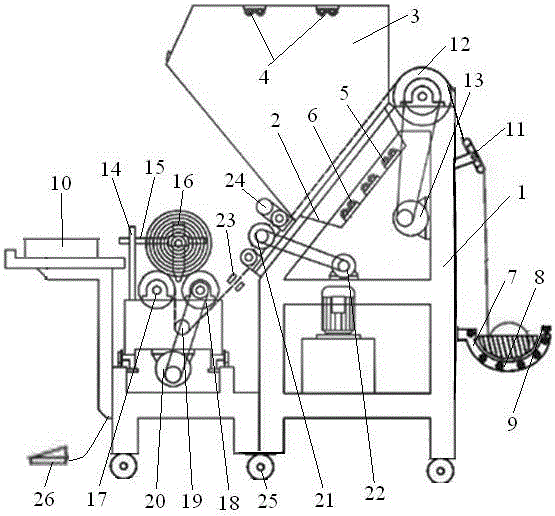

[0013] Embodiment 1: as figure 1 As shown, a fully automatic high-efficiency cloth inspection machine includes a frame 1 and an unwinding device arranged on the frame 1, a cloth inspection device, a winding device, an infrared deviation correction device 23, an electronic tension-free adjustment device, and an automatic metering device. Device 24 and automatic control box 10. The unwinding device includes a bowl-shaped cloth placing groove 7, an active cloth releasing roller 8, a zigzag frame 11 and a spreader roller 12. The spreader roller 12 can ensure that the cloth is prevented from curling when it enters the cloth inspection device. Shaped cloth placement groove 7 is fixedly installed on the back of the frame 1, and a plurality of active cloth placement rollers 8 are arranged in the bowl-shaped cloth placement groove 7. The zigzag frame 11 is installed above the bowl-shaped cloth placement groove 7 and near the display A width roller 12, the spreader roller 12 is driven ...

Embodiment 2

[0014] Embodiment 2: as figure 1 As shown, as an improvement of the present invention, the bottom of the frame 1 is provided with universal wheels 25 for easy movement, and an emergency stop foot brake 26 is provided at the front and bottom of the frame 1, which is convenient for emergency stop brakes in emergency situations. operate. The rest of the structures and advantages are exactly the same as in Embodiment 1.

Embodiment 3

[0015] Embodiment 3: as figure 1 As shown, as an improvement of the present invention, both the cloth running motor 13 and the cloth winding motor 20 are driven by frequency converters for speed regulation, and the frequency converters are electrically connected to the automatic control box 10 through encoders. The rest of the structures and advantages are exactly the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com