Automatic side alignment high speed cloth inspecting machine

A cloth inspection machine and automatic technology, which is used in the inspection of textile materials, textiles and paper making, etc., can solve the problems of poor use effect of rewinding and unwinding and cloth inspection machine, poor continuous operation ability, and large overall size of the equipment. The effect of continuous and stable cloth inspection, labor saving and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

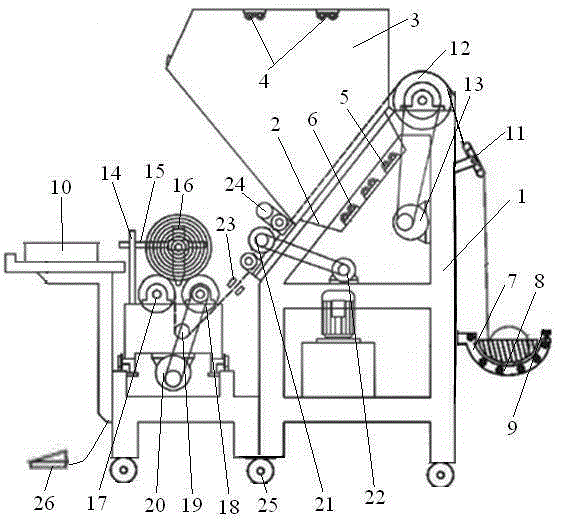

[0016] Example 1: like figure 1 As shown, an automatic edge-aligning high-speed cloth inspection machine includes a frame 1 and an unwinding device arranged on the frame 1, a cloth inspection device, a winding device, an electric eye automatic edge-aligning device 23, and an electronic tension-free adjustment device , an automatic metering device 24 and an automatic control box 10, the electronic tension-free adjustment device is arranged between the cloth inspection device and the winding device, and the electronic tension-free adjustment device includes a tension detector and a guide with adjustable line speed The cloth rubber roller 21, the tension detector is arranged on the cloth guide rubber roller 21, one end of the cloth guide rubber roller 21 is connected to the pressure regulating device through the oil pipeline, and the other end is connected to the gear reduction motor 22 through a belt; the electric eye automatically The edge alignment device 23 is arranged belo...

Embodiment 2

[0017] Example 2: like figure 1 As shown, as an improvement of the present invention, the cloth inspection device includes an inclined cloth inspection table 2 and a condenser cover 3, the condenser cover 3 completely wraps the cloth inspection table 2, and is set on the condenser There are multiple cloth inspection lights 4, and the cloth inspection table 2 is made of trapezoidal grooves plus non-reflective glass, and multiple sets of linear array CCD cameras 5, linear array LED light sources 6 and lenses are arranged at the bottom of the trapezoidal grooves. The bottom of frame 1 is provided with the universal wheel 25 that is convenient to move, and the front lower part of frame 1 is provided with emergency stop foot brake 26, is convenient to the operation of emergency stop brake in case of emergency. The rest of the structures and advantages are exactly the same as in Embodiment 1.

Embodiment 3

[0018] Example 3: like figure 1 As shown, as an improvement of the present invention, the unwinding device includes a bowl-shaped cloth placing groove 7, an active cloth releasing roller 8, a zigzag frame 11 and a spreader roller 12, and the spreader roller 12 can ensure that the cloth is placed in the inspection To prevent the cloth from curling during the cloth device, the bowl-shaped cloth placing groove 7 is fixedly installed on the back of the frame 1, and a plurality of active cloth releasing rollers 8 are arranged in the bowl-shaped cloth placing groove 7, and the zigzag frame 11 is installed on the The bowl-shaped cloth is placed above the groove 7 and close to the spreader roller 12. The spreader roller 12 is driven by a cloth-running motor 13, and a belt drive is used between the spreader roller 12 and the cloth-running motor 13 shafts. An infrared detector 9 is arranged at the notch of the cloth placement groove 7, and the infrared detector 9 is electrically conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com