Engaging and disengaging mechanism of electronic core insertion lock

A clutch mechanism and mortise lock technology, applied in building locks, building structures, non-mechanical transmission-operated locks, etc., can solve the problems of poor universality of electronic mortise locks, and achieve the effect of good universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

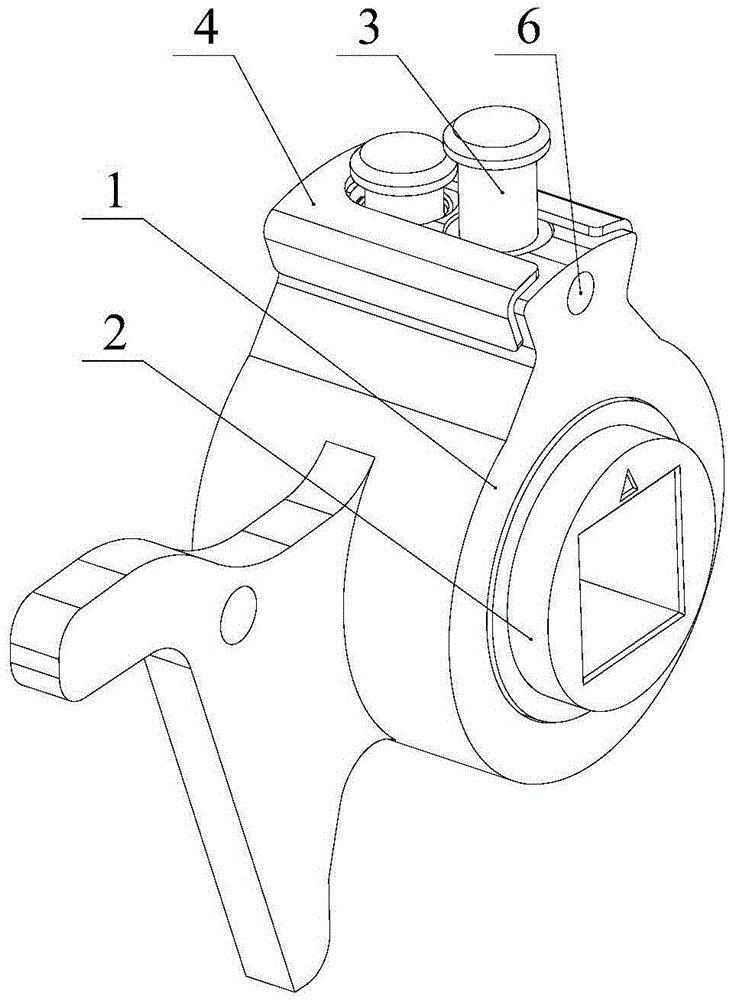

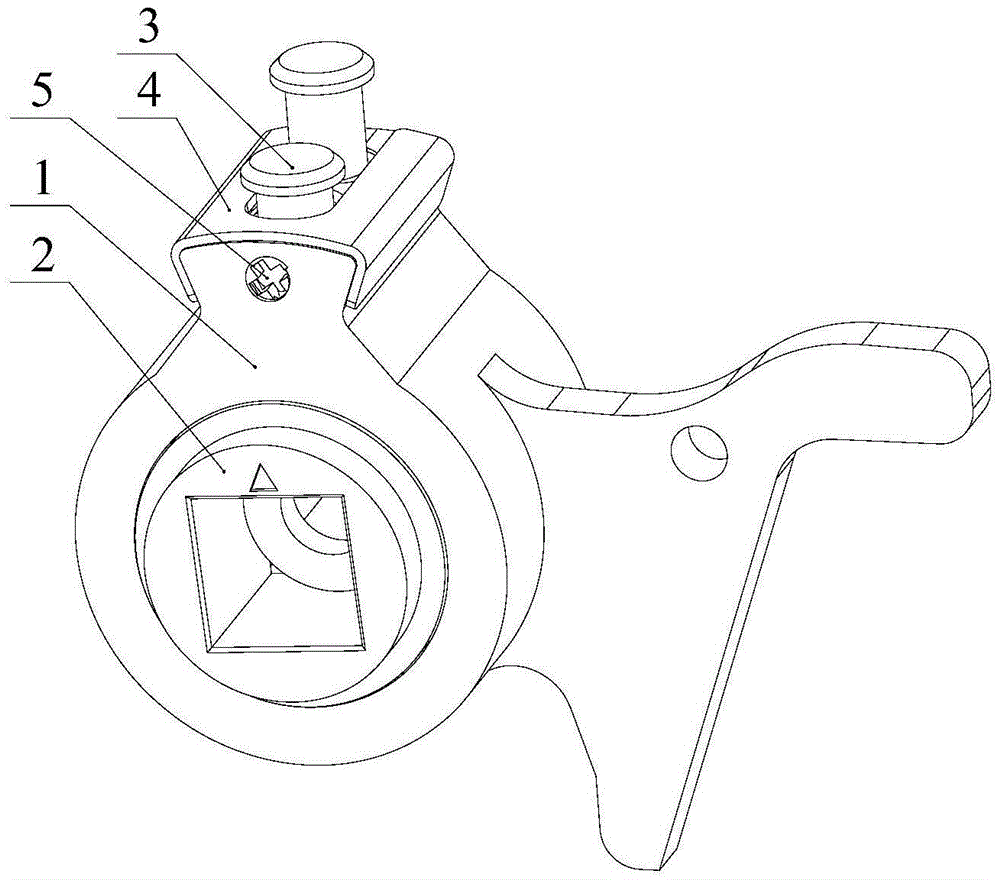

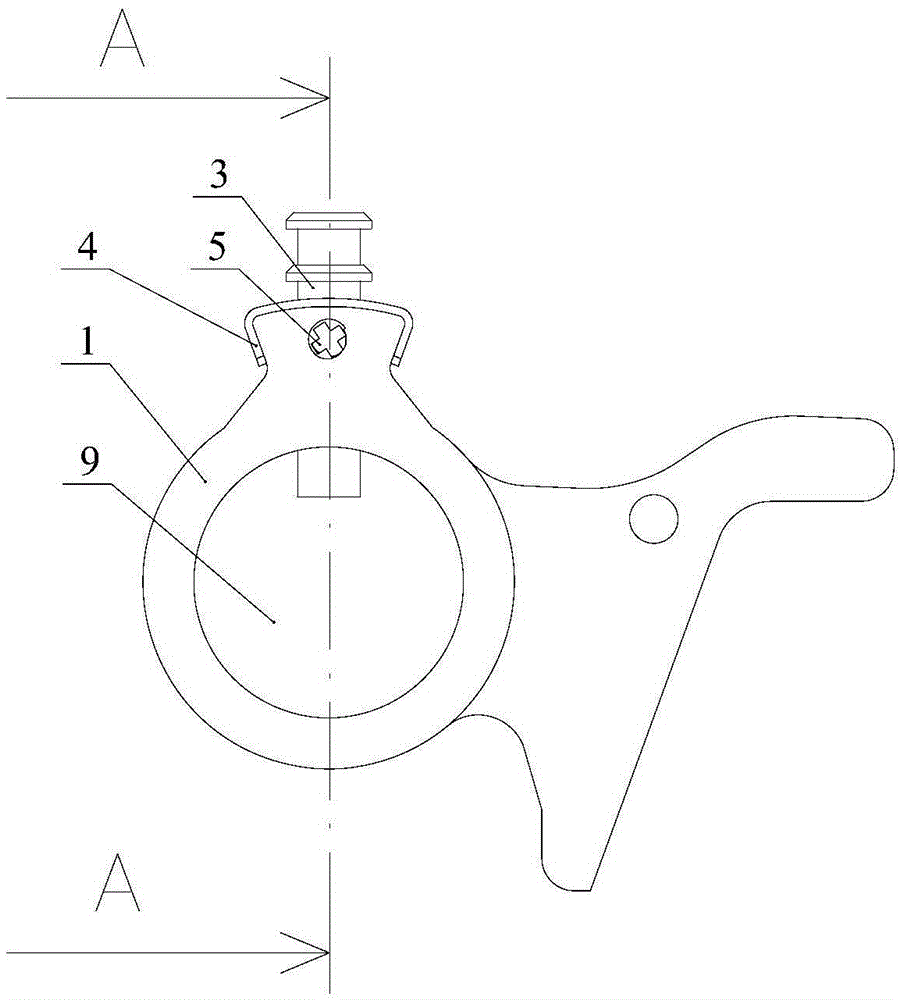

[0046] Such as Figure 1~5 As shown, a clutch mechanism of an electronic mortise lock, including:

[0047] The main transmission part 1 has a cylindrical through hole 9, and the side wall of the main transmission part 1 has two clutch shaft installation holes 17 arranged at intervals, and each clutch shaft installation hole 17 communicates with the through hole 9. In this embodiment , in order to make the fit better, the axis of the clutch shaft mounting hole 17 is perpendicular to the axis of the through hole 9;

[0048] Two clutch parts 2, each clutch part has a fitting part 24 that stretches into the through hole and is rotatably matched with the through hole. Both have a limit groove 11 that matches the mounting hole of the clutch shaft;

[0049] The clutch shaft 3 is slidably installed in the corresponding clutch shaft installation hole 17, and the main transmission part is locked by controlling the clutch shaft to extend into the corresponding limiting groove, and the ...

Embodiment 2

[0064] Such as Figure 9 As shown, the difference between this embodiment and embodiment 1 is that the matching anti-off parts and the main transmission part are slightly different from embodiment 1. In this embodiment, the side wall of the protrusion of the main transmission part 1 is provided with a limit Position chute 22, the anti-off part has a sliding part 23 that cooperates with the limit chute 22, and an anti-off part 26 that cooperates with the middle side wall of the protrusion, and the anti-off part 26 has a notch for the clutch shaft to pass through, And the notch cooperates with the limit ring to prevent the limit ring from breaking away from the mounting hole of the clutch shaft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com