Infrared Ray Bridge Concrete Component Dimension Detection Device

A size detection and infrared ranging technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of large safety hazards, no public reports, safety hazards, etc., achieve energy saving and emission reduction effects, and collect a large amount of data , the effect of high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

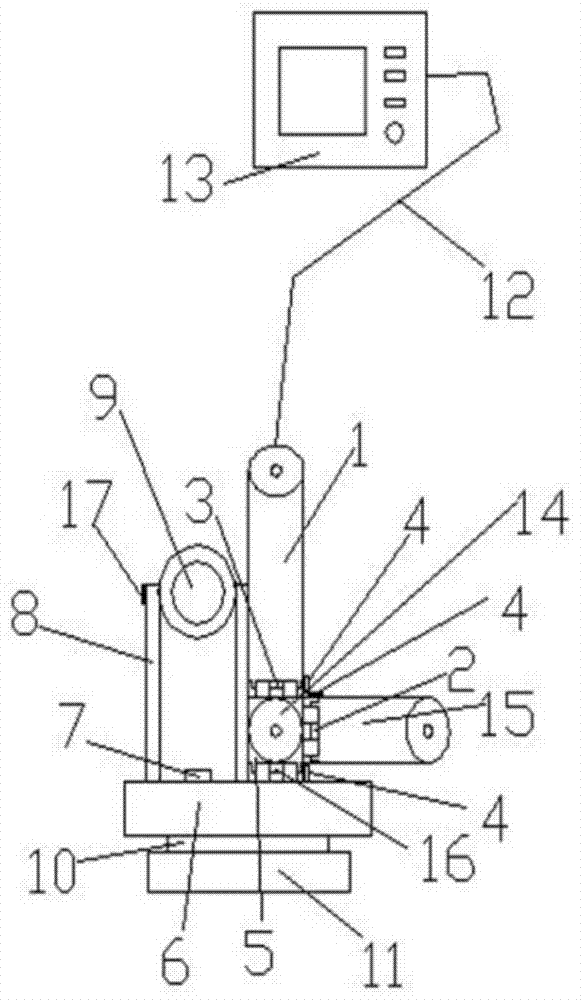

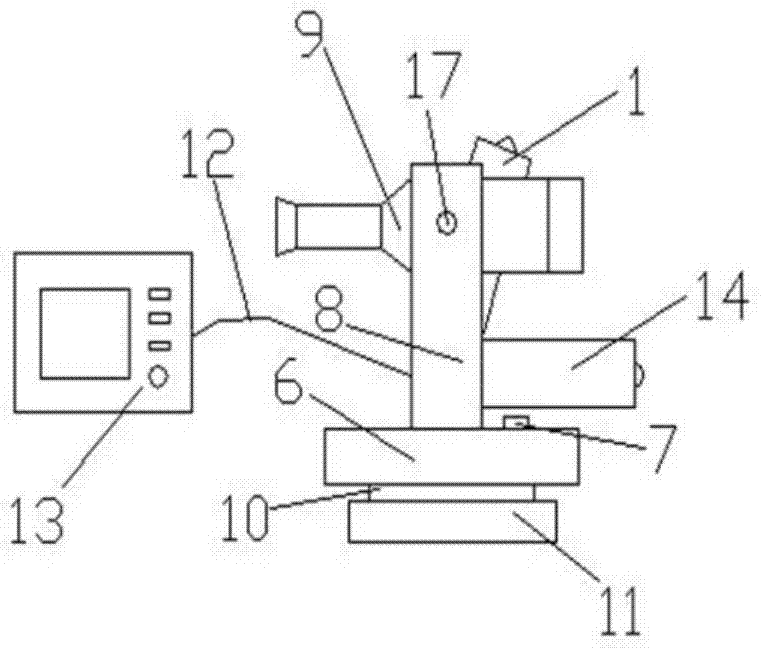

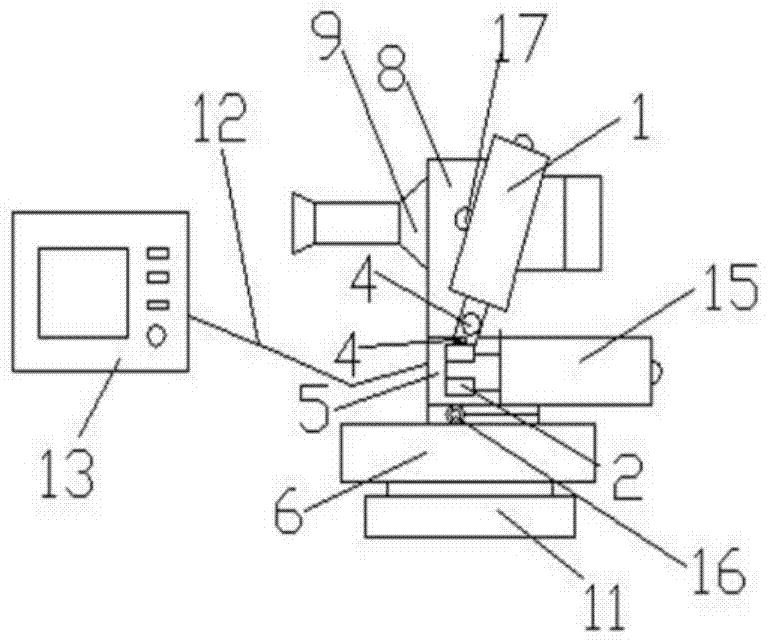

[0024] As shown in the figure, the bridge concrete component size detection device of the present invention consists of a vertical infrared rangefinder 1, a horizontal angle measuring instrument 2, an upper vertical angle measuring instrument 3, an angle measuring instrument fixing bolt 4, a connecting support 5, a cylinder Shaped horizontal support 6, leveler 7, support 8, observation telescope 9, cylindrical rotating support 10, tripod support 11, data transmission cable 12, data storage device 13, center infrared range finder 14, horizontal direction infrared The rangefinder 15, the lower vertical angle measuring instrument 16, and the observation telescope fixing bolt 17 are formed;

[0025] The main functions of each part are: the vertical infrared rangefinder 1 collects the distance data between the observation point and the concrete measuring point, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com