Establishment of performance prediction model of high-alumina bronze coating and optimization method of single performance index

A high-alumina bronze and predictive model technology, applied in the direction of instruments, calculations, electrical digital data processing, etc., can solve the problem of inability to determine the optimal value of the performance index process parameters, increase the cost and cycle of high-alumina bronze coating research and development, and make it difficult Accurate prediction of coating properties and other issues to achieve the effect of being directional and forward-looking, simplifying formulation, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The method for establishing the behavior prediction model of the high-alumina bronze coating of the present embodiment comprises the following steps:

[0053] S1: Establish training samples and test samples.

[0054] Specifically, it includes the following three steps:

[0055] S11: Select the input variables and output variables of the high-aluminum bronze coating behavior prediction model.

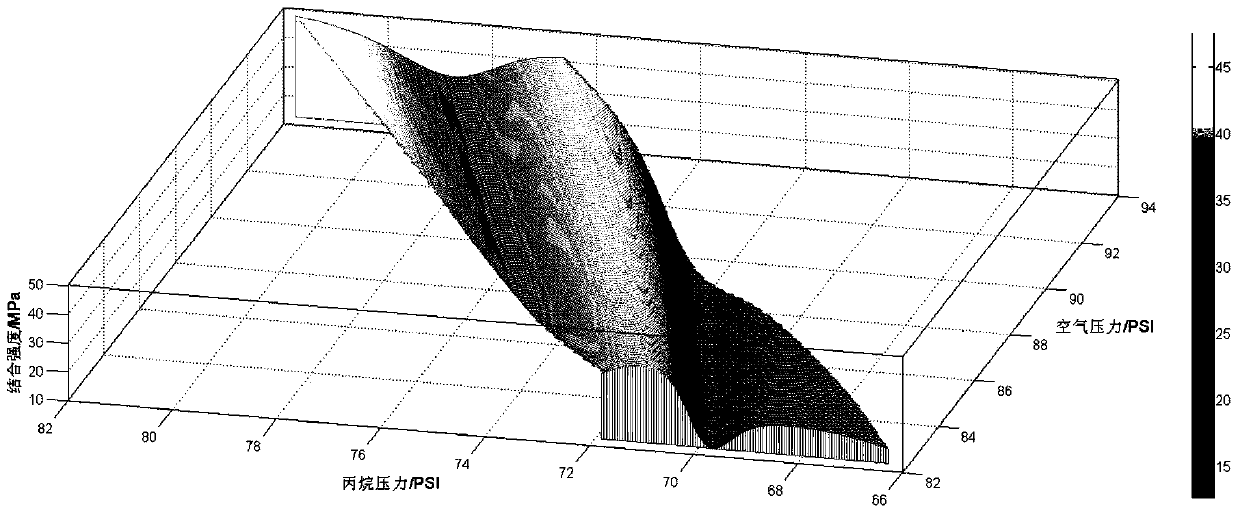

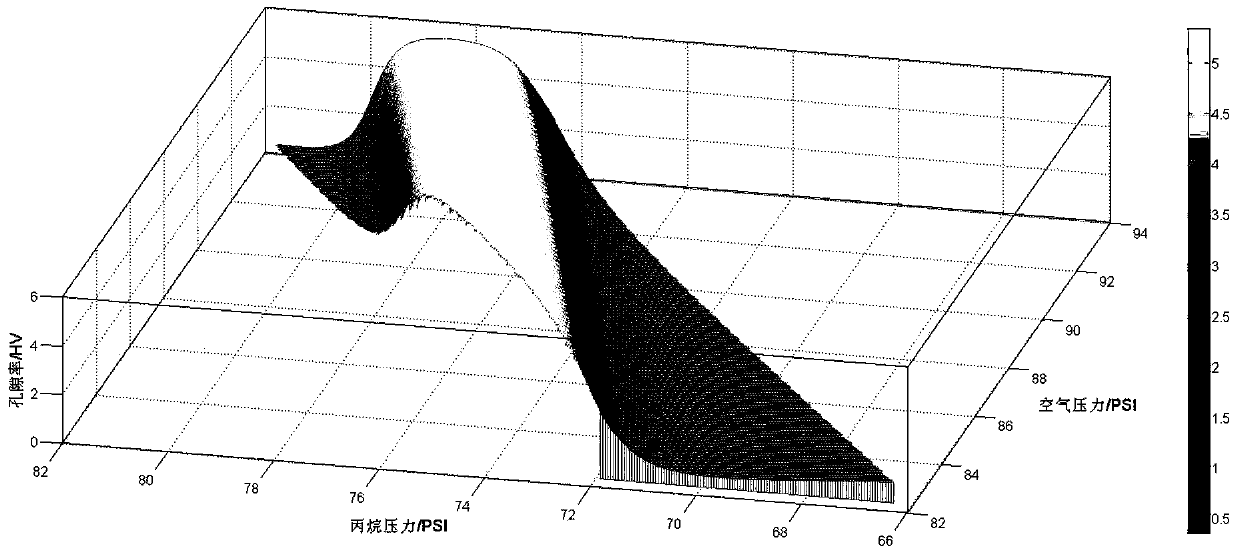

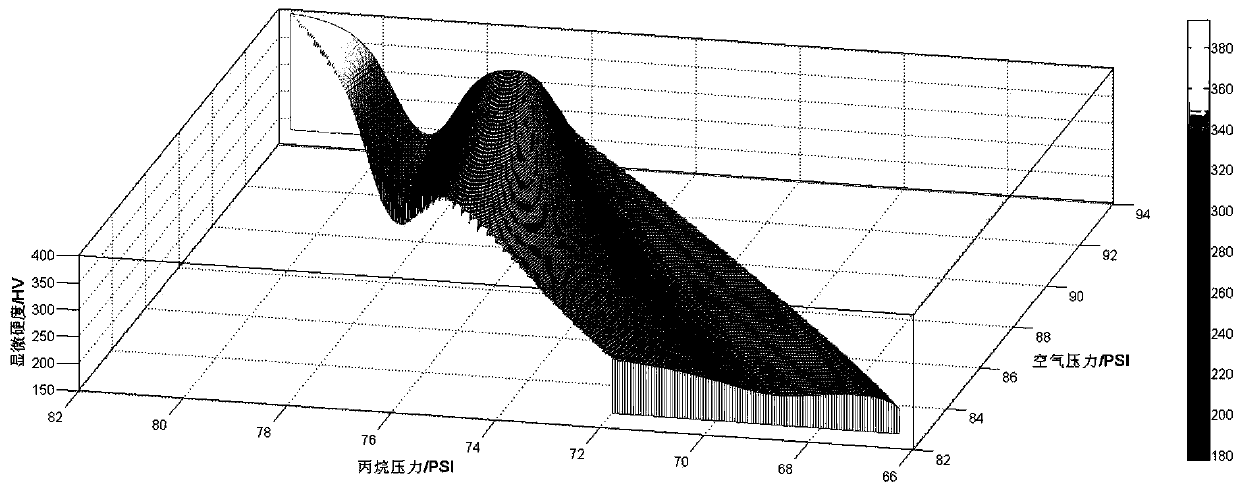

[0056] Among them, the process parameters such as spraying distance, powder feeding rate, spray gun linear speed, air pressure and propane pressure are used as input variables, and the performance indicators such as bonding strength, porosity, microhardness and oxygen content are used as output variables.

[0057] S12: Use low-temperature supersonic spraying technology to prepare high-alumina bronze coatings with uniform and discrete spraying process parameters in a laboratory environment, complete the performance index test of high-alumina bronze coatings, and collect experiment...

Embodiment 2

[0091] In this embodiment, the performance prediction model of the high-alumina bronze coating established in step S4 is used to optimize the extreme value of a single performance index of the high-alumina bronze coating through a genetic algorithm.

[0092] Specifically as follows: adopt the method of real number coding, process parameter is used as the population individual in the genetic algorithm, the each performance index predictive value (wherein binding strength, microhardness) of the high-alumina bronze coating behavior prediction model output that step S4 obtains Take its reciprocal) as the individual fitness value in the genetic algorithm, the smaller the fitness value, the better the individual. The optimal value of each performance index and its corresponding process parameters are deduced through the selection operator, crossover operator and mutation operator (same as step S3).

[0093] Wherein the optimal process parameters of each performance index are shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com