Floating Roller Traction-Driven Card Collector for Cards of Different Thicknesses

A technology of traction drive and floating roller, which is applied in the direction of computer components, instruments, transmission record carriers, etc. It can solve the problems of small bite force between the roller and the card, cannot float up and down, and affects work efficiency, etc., and achieves great card thickness compatibility. , large bite force, large friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

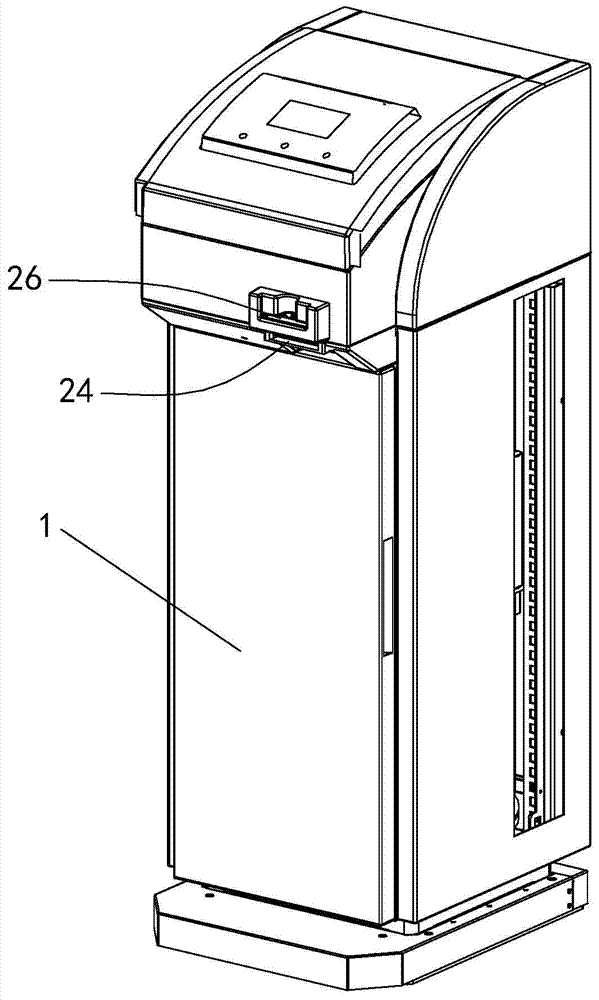

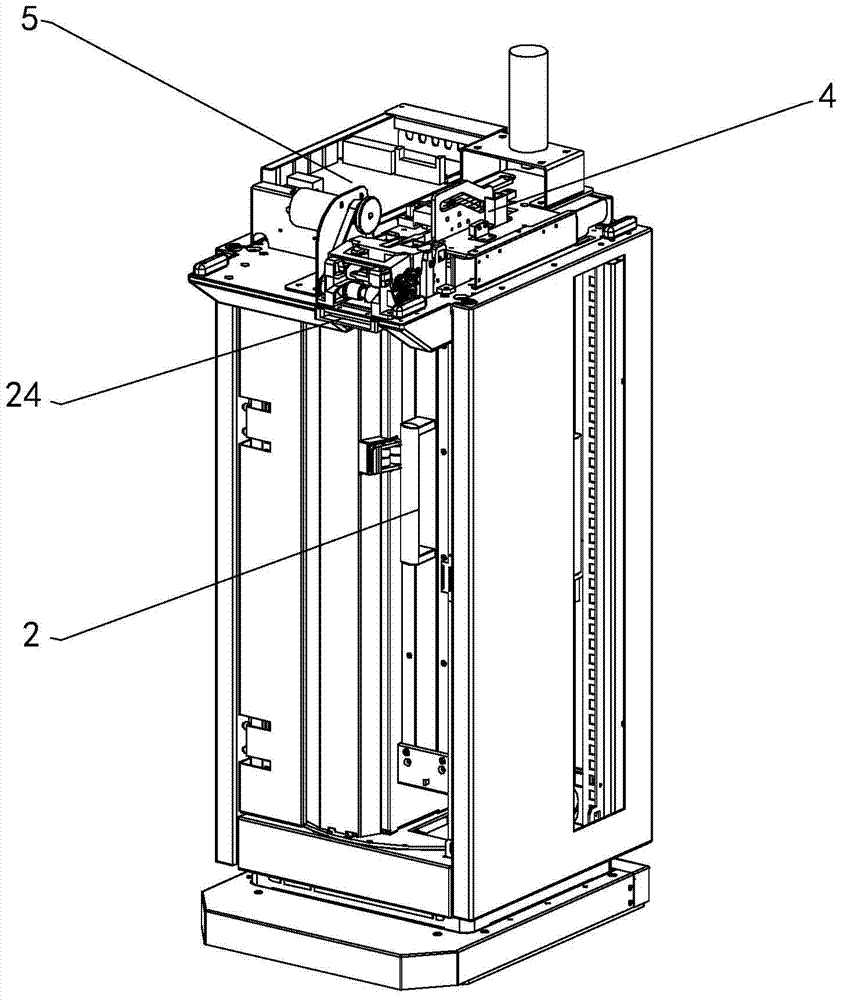

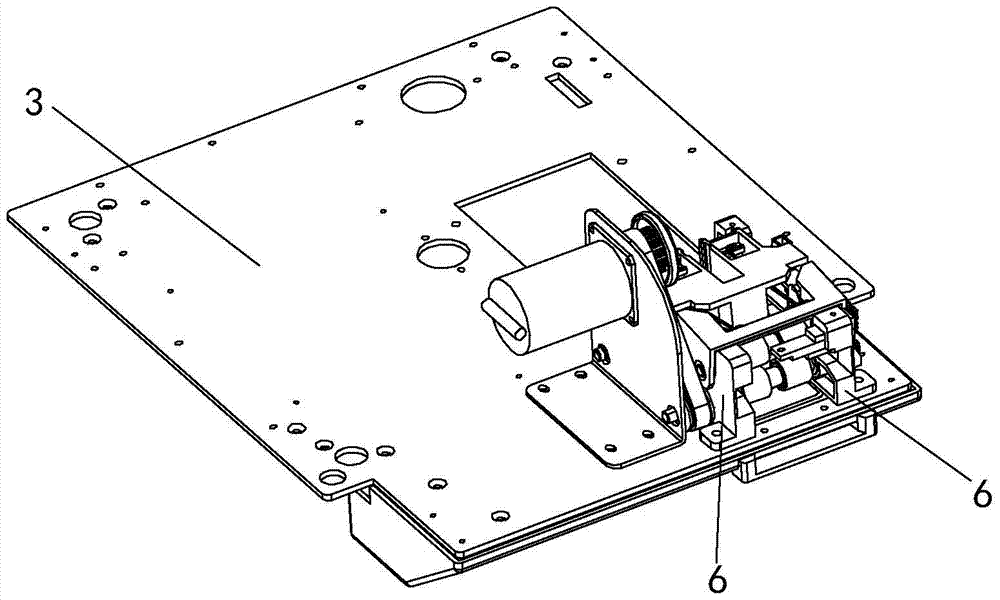

[0042] Such as Figure 1 to Figure 11 The shown front floating roller traction-driven card collector for collecting cards of different thicknesses includes a casing 1, a card holder 2, a mounting base plate 3, a traction device, a card collecting device 4, a driving device and a control device, and the installation The base plate 3 is a hollow plate frame with openings. The mounting base plate 3 is horizontally and fixedly arranged in the casing 1 and is located above the clip 2. The clip 2 is arranged vertically. The clip 2 has a slot and a bayonet for storing The card cavity of the card and the supporting card mechanism that drives the card in the cavity to move upwards and output the card from the cavity, the traction device and the card collection device 4 are both arranged on the installation substrate 3, and the traction device is compatible with the bayonet of the card holder 2 , used to pull the card from the card inlet 26 of the card collector to the card holder 2, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com