Sucking disc cover with convex ribs and sucking disc

The technology of a suction cup cover and ribs is applied to a suction cup. It can solve the problems of low load-bearing capacity and durable performance of the suction cup, insufficient pressure contact area, and insufficient suction of the suction cup, and achieve the effects of simple structure, convenient production and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

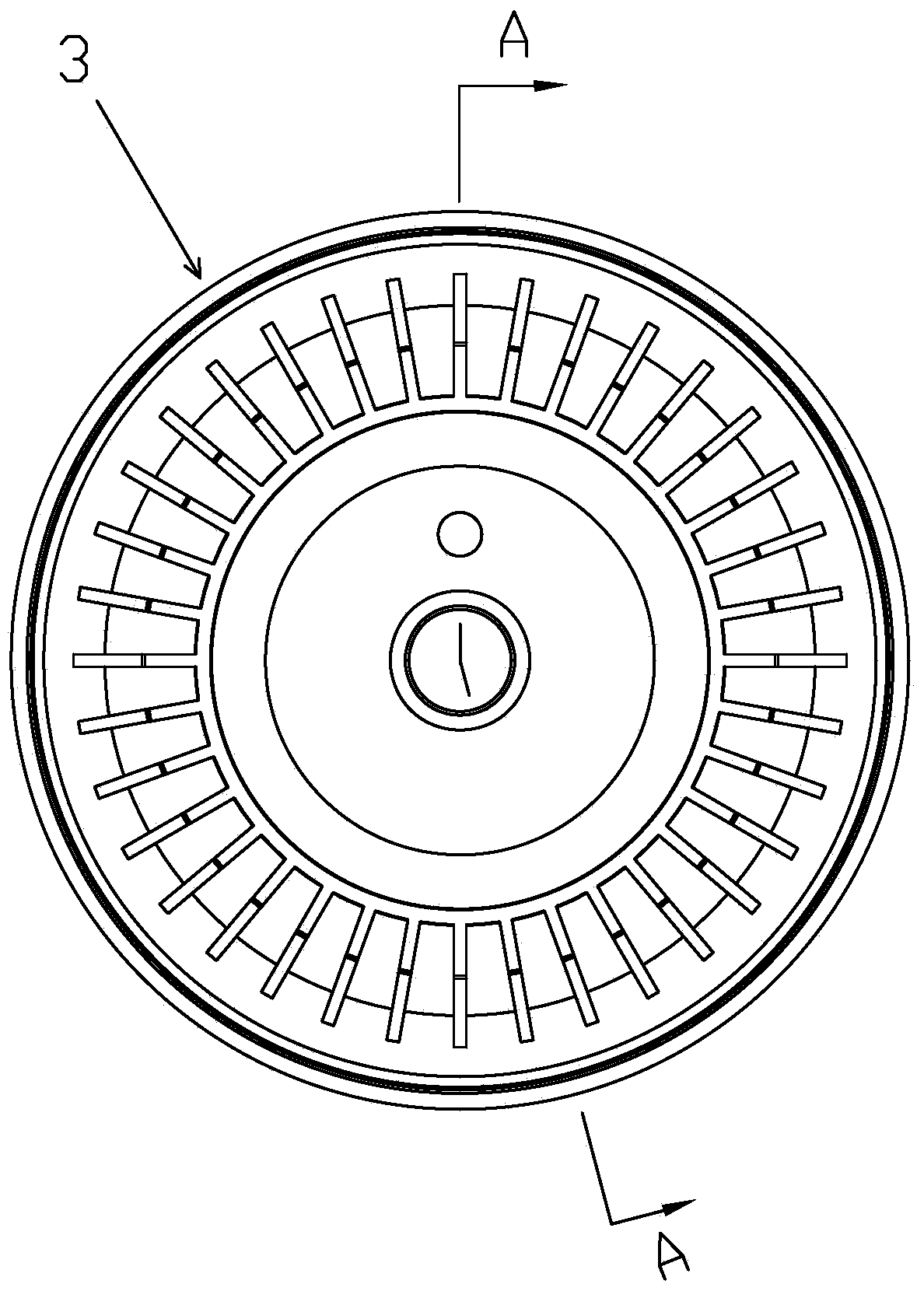

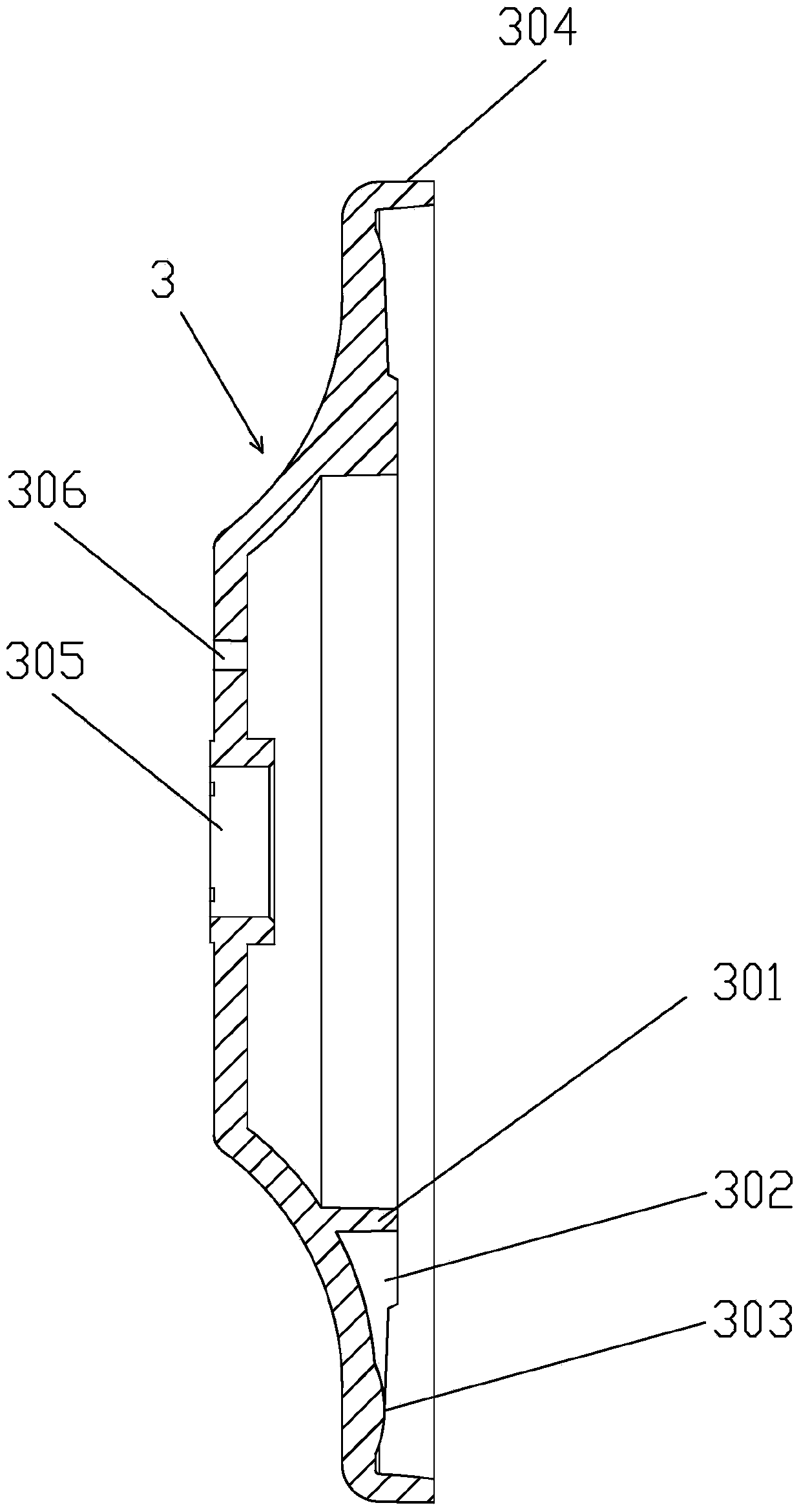

[0030] Such as Figure 1 to Figure 2 As shown, a suction cup cover with ribs includes a housing 304 with an open end, a through hole 305 is provided in the middle of the bottom surface of the housing 304, and a connecting rod from the housing is provided on the periphery of the through hole 305. 304 is an inner convex ring 301 whose bottom surface extends toward the opening side, and a plurality of ribs 302 are arranged on the outer side of the inner convex ring 301 .

[0031] The ribs 302 are arranged radially on the outside of the inner convex ring 301

[0032] An outer convex ring 303 is disposed on the periphery of the inner convex ring 301 , and the convex ribs 302 are arrayed circumferentially between the inner convex ring 301 and the outer convex ring 303 .

[0033] A concave platform 3021 is provided on the raised rib 302 .

[0034] The suction cup cover 3 is provided with a positioning hole 306 . Positioning holes 306 are provided to cooperate with external positio...

Embodiment 2

[0041] Such as Figure 8 to Figure 9 Shown, the difference of embodiment 2 and embodiment 1 is:

[0042] The pressing part 5 is a lever hinged with the upper end of the connecting rod 101, and the lever is provided with a protruding part 701 for pressing the back of the suction cup cover 3 when the suction cup is in use. .

[0043] The suction cup of the present invention can be used for hangers such as suction cup hooks and suction cup hanging baskets that need to be side hung on smooth, rough, dense and airtight walls.

[0044] The working principle of the present invention:

[0045] The working principle of embodiment 1:

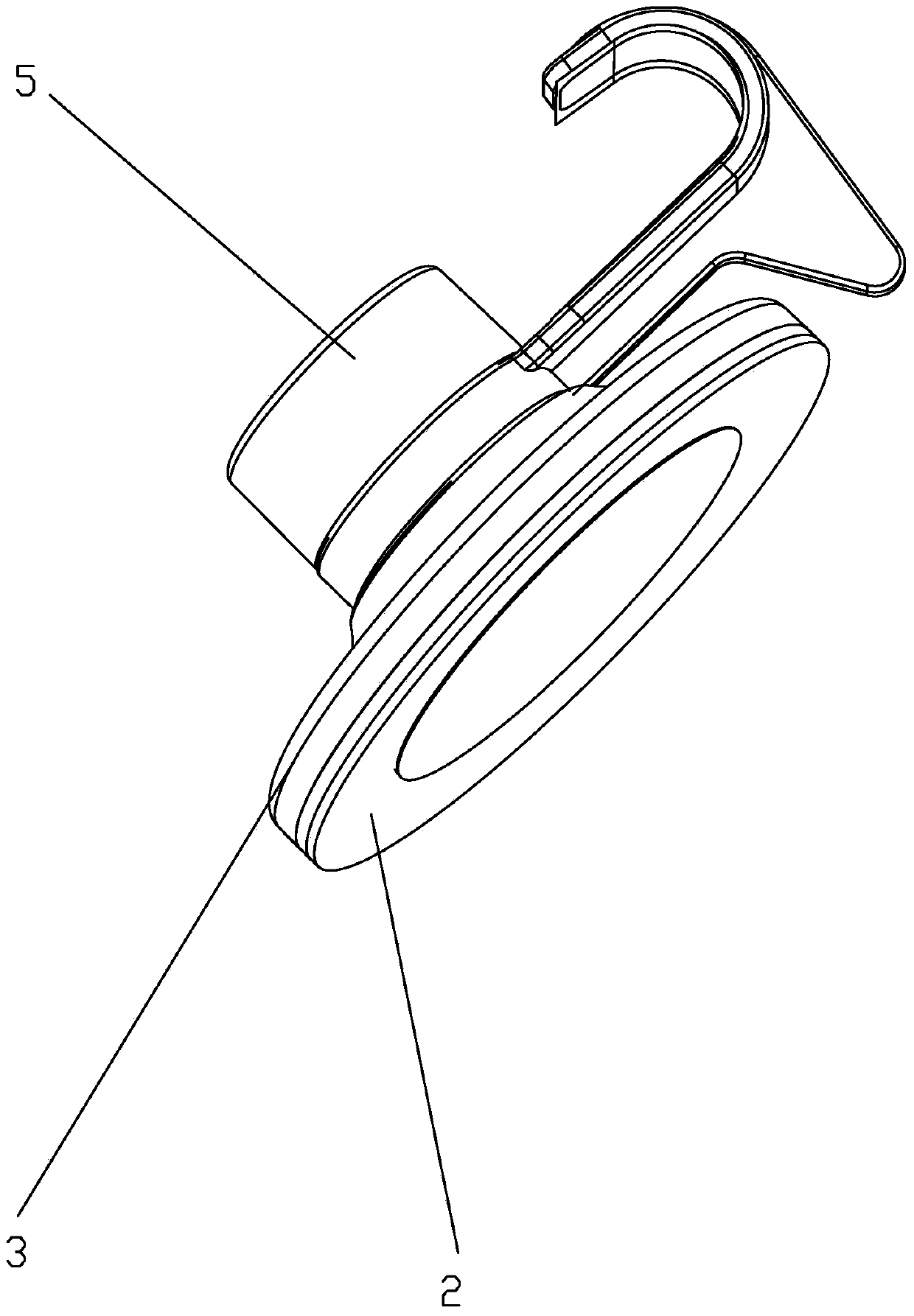

[0046] Such as Figure 6 As shown, when in use, the suction cup is pressed on the base surface 10, the bottom surface of the elastic colloid 2 is attached to the base surface 10, and then the pressing member 5 is rotated, and the pressing member 5 presses the suction cup cover 3, and the suction cup cover 3 The radial ribs 302 of the elastic colloid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com