Capacitor cover floating riveting mechanism

A technology for riveting mechanism and capacitor cover, applied in capacitors, capacitor manufacturing, circuits, etc., can solve the problems of uneven force on the terminals of the cover, scrapped products, deformation of the cover, etc., to eliminate adverse effects, rational structure, and improve production. The effect of efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

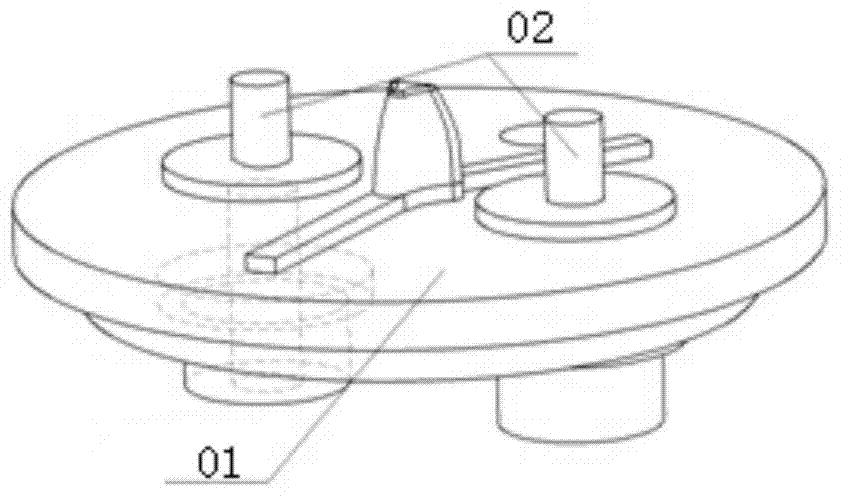

[0036] The manufacturing process of aluminum electrolytic capacitors mainly includes nailing and winding of electrode foil and electrolytic paper, electrolyte impregnation, pin puncture, cover riveting, aluminum shell glue filling, core packing into shell, aluminum shell sealing, high temperature aging, casing Pipe coating and other processes. After the puncture hole cutting of the capacitor core package pins is completed, the cover plate needs to be riveted. The material of the cover plate is phenolic resin, the material of the terminal is aluminum, the main body of the cover plate 01 and the two terminals 02 are integrally formed, such as figure 1 shown.

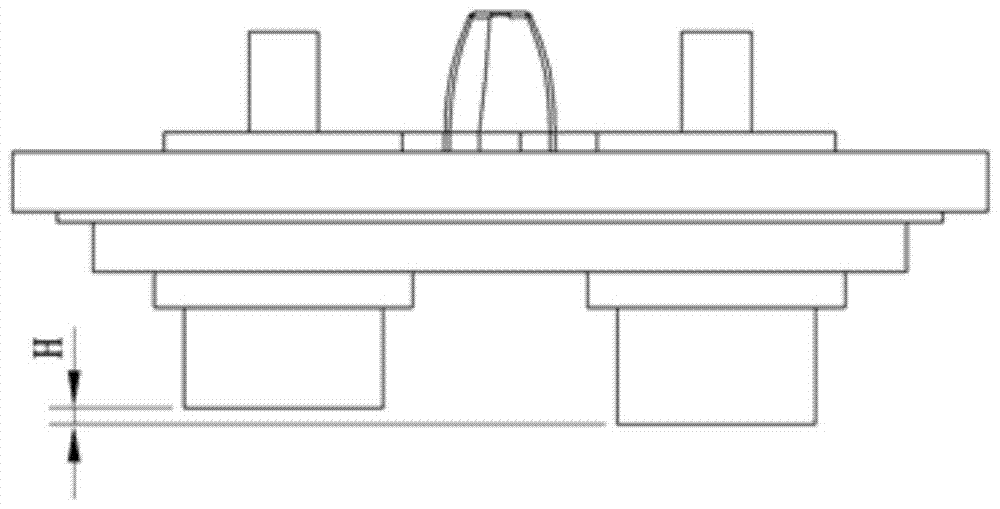

[0037] Capacitor cover plates are generally manufactured by professional manufacturers. Due to technological reasons, there are errors in the flatness and height of the two terminals 02 of the cover plate, such as figure 2 shown.

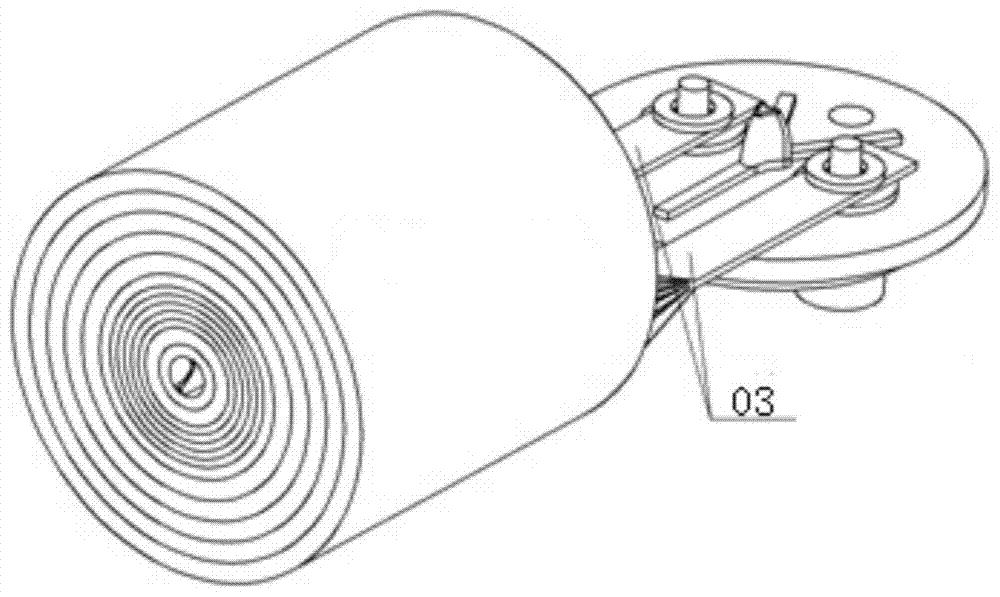

[0038] The capacitor pin 03 after the puncture cutting is installed on the cover plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com