Pit-in-pit supporting structure and construction method of local flow-plastic muddy soil

A technology for supporting structures, silty soils, applied in the direction of foundation structure engineering, excavation, construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to facilitate the understanding of the structure of the present invention, the following description will be made in conjunction with the accompanying drawings and embodiments.

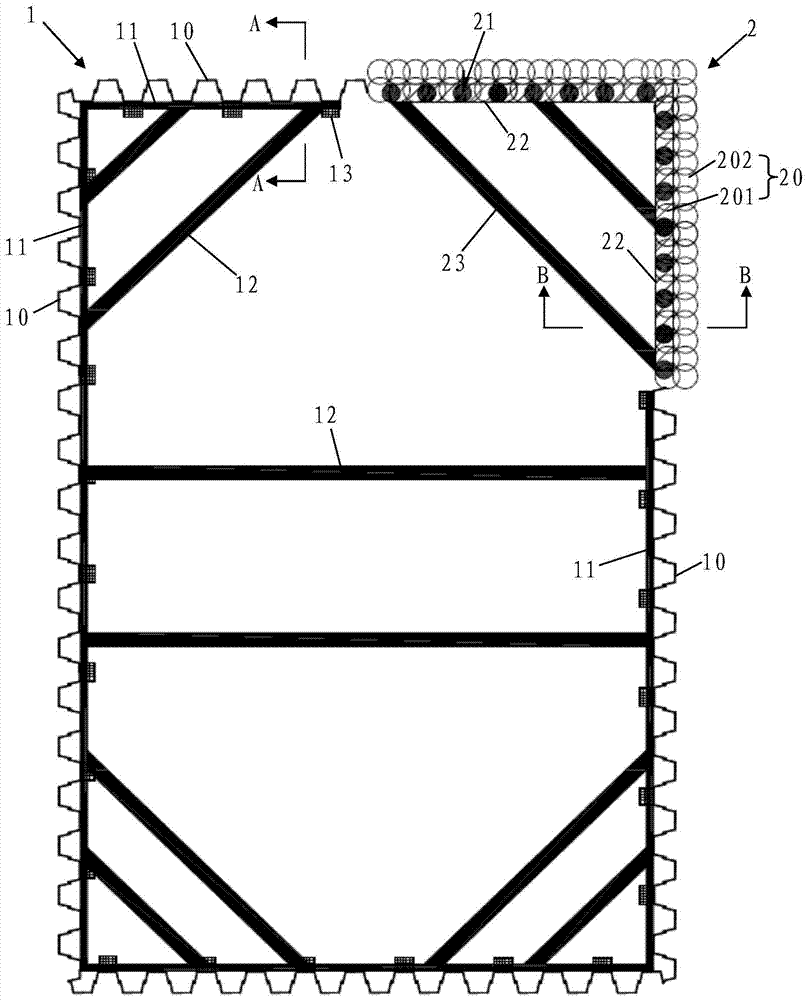

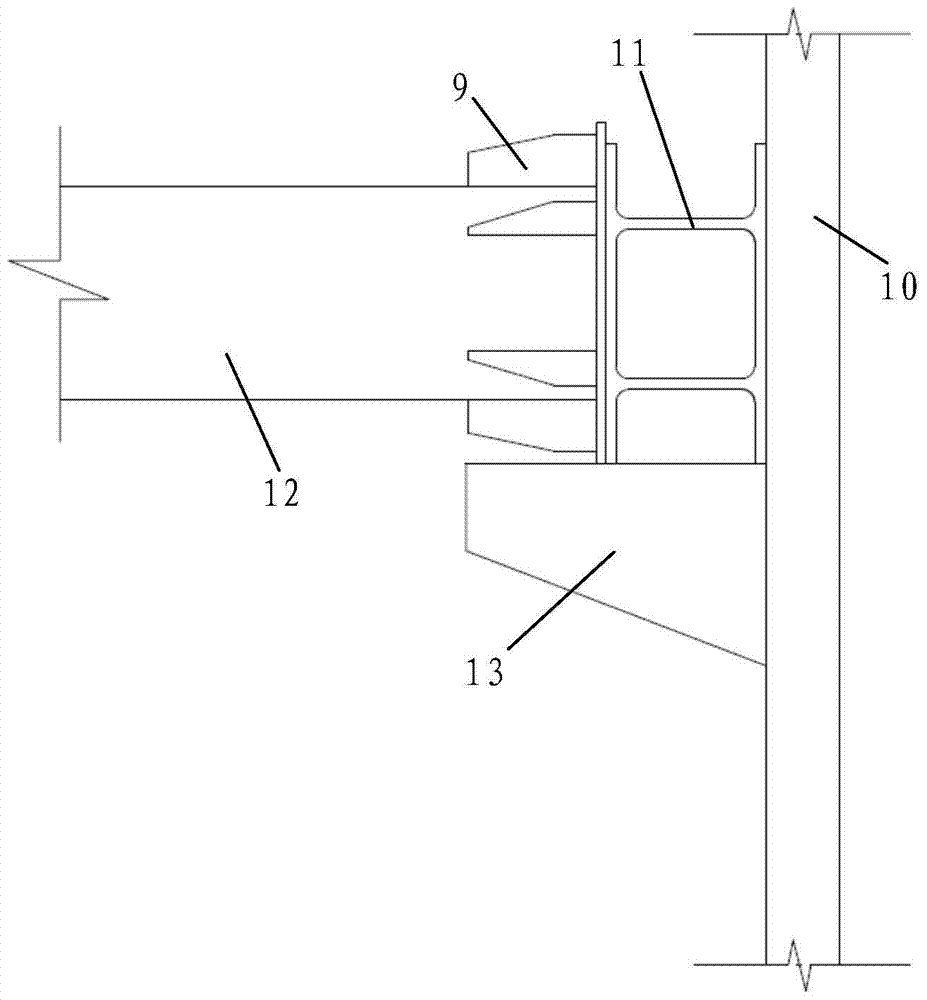

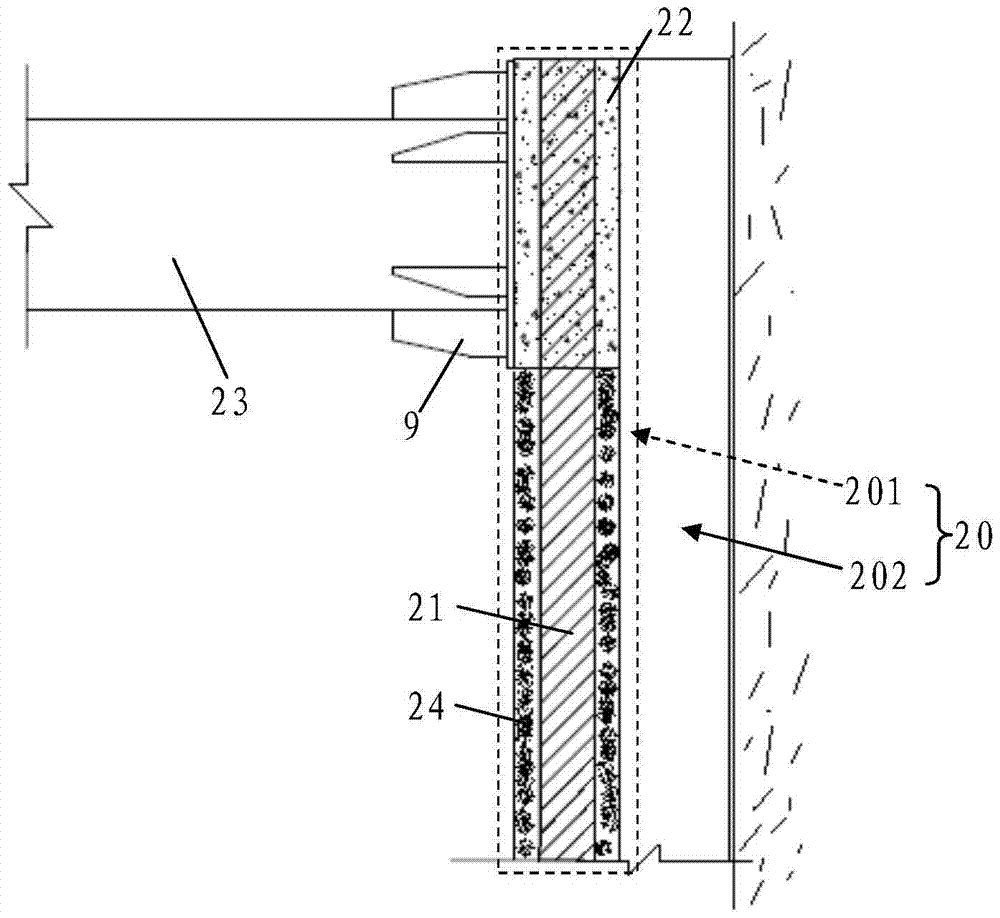

[0036] refer to figure 1 , is a schematic diagram of the overall planar structure of the pit supporting structure of the local fluid-plastic muddy soil mass of the present invention. like figure 1 As shown, the present invention provides a pit-in-pit support structure with local fluid-plastic muddy soil. There are ordinary soil areas and muddy soil areas in the pit-in-pit. The support structure includes the first A support structure 1 and a second support structure 2 supported in the muddy soil area, the first support structure 1 and the second support structure 2 are mutually enclosed and connected; wherein, the first support structure 1 includes: A plurality of steel sheet piles 10 are respectively arranged on the side of the common soil area; purlins 11 surround the inner side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com