Out-of-tolerance product removal mechanism for weighing equipment

A technology for removing mechanisms and equipment, applied in sorting and other directions, can solve the problems of easy damage of parallel moving devices, increase production costs, affect product use, etc., and achieve the effect of reducing component replacement, saving production costs, and long service life of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0016] Example 1

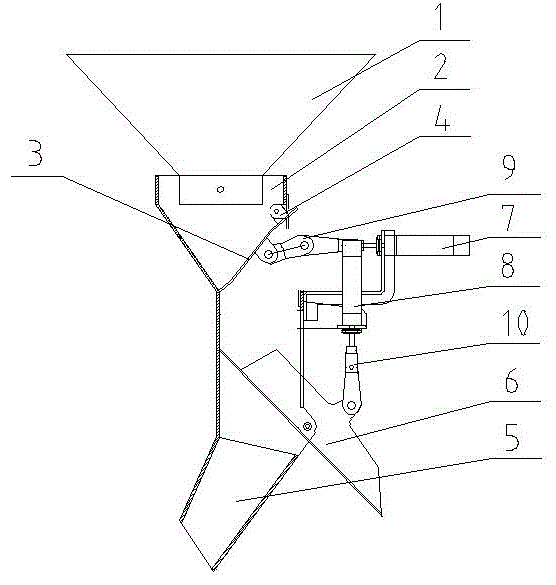

[0017] The present invention is an out-of-tolerance rejection mechanism for weighing equipment, which is characterized by comprising a feed hopper 1, a collection hopper 2, a collection hopper gate 3, a rotating shaft 4, a discharge hopper 5, a rejection hopper 6, a drive device, and a drive The drive device includes a first drive device 7 and a second drive device 8. The drive shaft includes a first drive shaft 9 and a second drive shaft 10. The feed hopper 1 and the collection hopper 2 are connected, and the collection hopper 2 is installed on the lower side of the collection hopper. The hopper gate 3, the collection hopper gate 3 is fixed on the collection hopper 2 through the rotating shaft 4, the first drive shaft 9 is connected to one side of the collection hopper gate 3, and the first drive shaft 9 is connected with the first drive device 7. The collection hopper 2 A discharge hopper 5 is installed on the lower side. The discharge hopper 5 is connected t...

Example Embodiment

[0018] Example 2

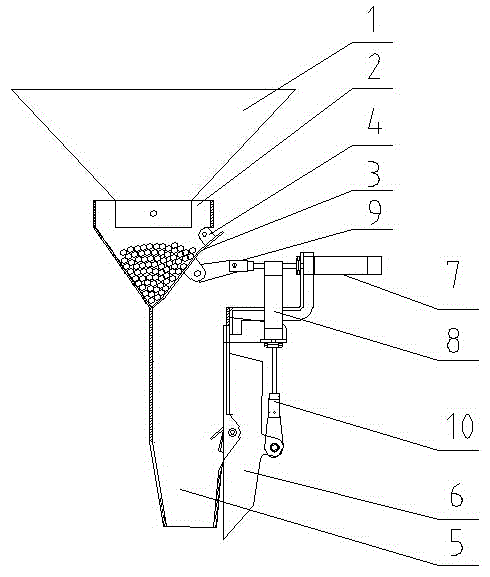

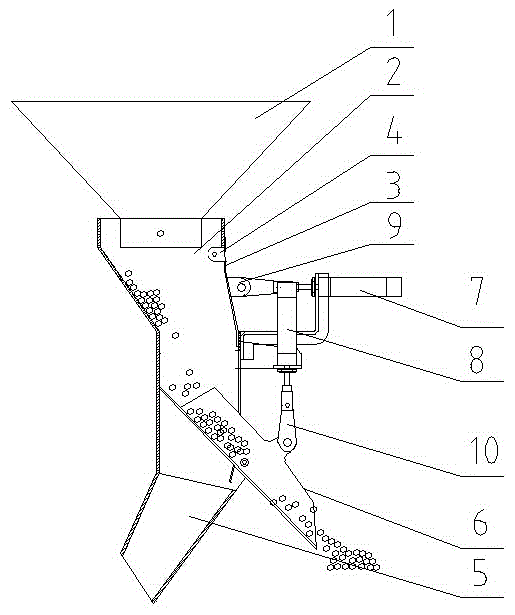

[0019] When in use, the product to be tested is put into the weighing device, and the weighing device acts on it. The product to be tested falls into the present invention through the action of the weighing device, and falls into the collection hopper 2 through the feed hopper 1. When the product needs to be tested When the requirements of the weighing device setting are not met, the weighing device transmits the information to the drive device. The first drive device 7 and the second drive device 8 act on the drive shaft according to the instruction, and the second drive shaft 10 is lifted up to drive the rejection The hopper 6 moves upward, and then the first drive shaft 9 moves backward, which in turn drives the collection hopper door 3 to move backward, the collection hopper door 3 is opened, and the unqualified products in the collection hopper 2 are rejected to the outside through the rejection hopper 6. When the product to be detected meets the requireme...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap