Novel propelling mechanism for double bookbinding machines

A technology of a propulsion mechanism and a binding machine, applied in binding and other directions, can solve problems such as unguaranteed, affecting the appearance of documents, affecting the quality of binding, etc., and achieve the effect of beautiful binding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

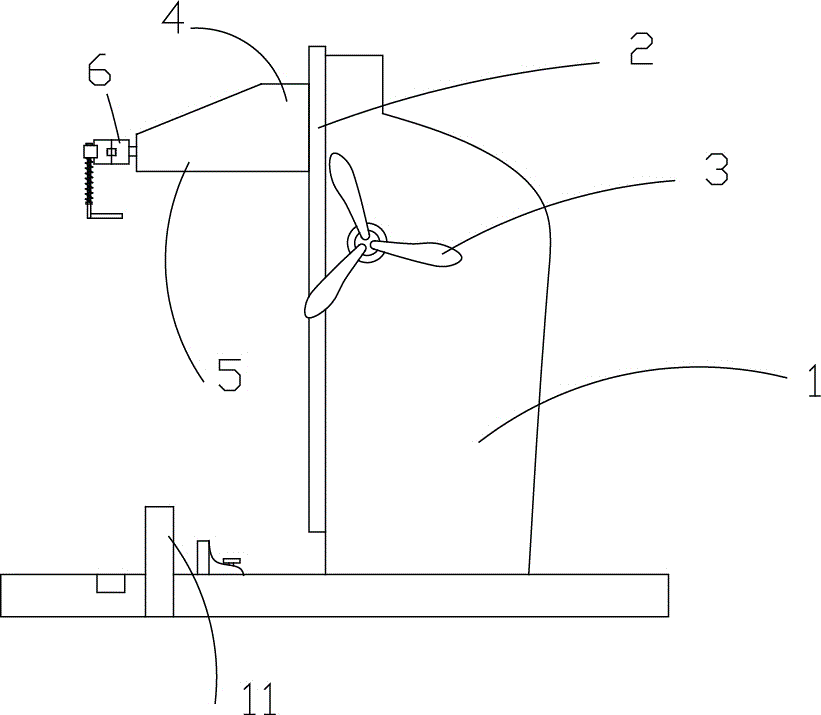

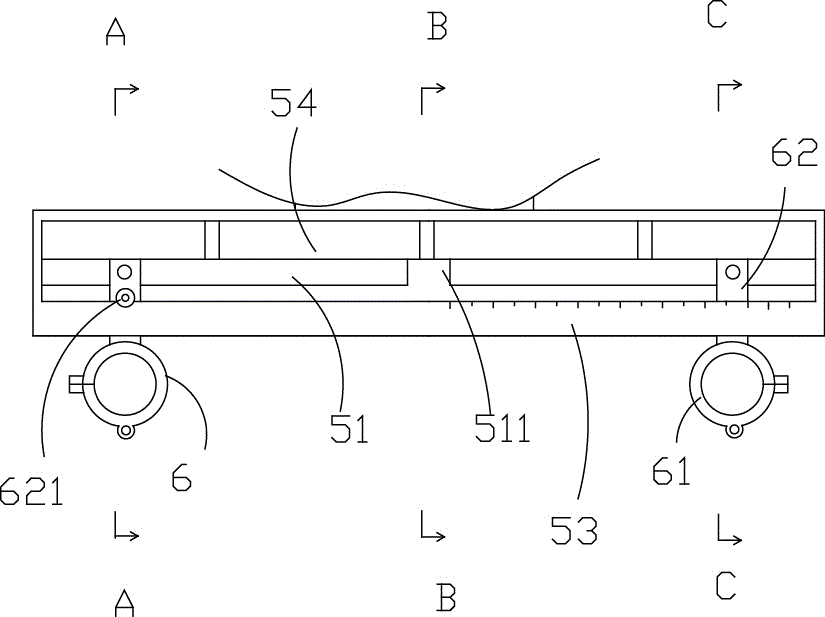

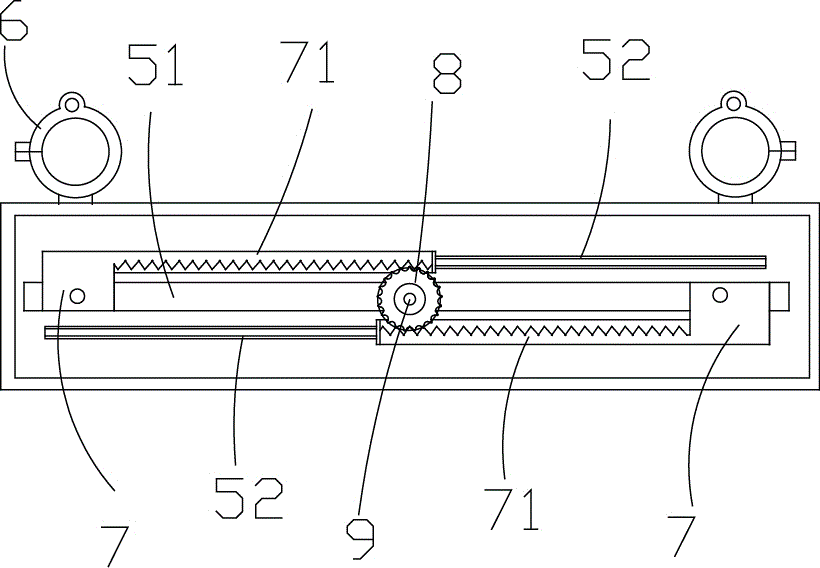

[0026] Such as Figure 1 to Figure 8 Shown is the structural representation of the present invention,

[0027] The reference signs therein are: bracket 1, guide 2, feed unit 3, propulsion unit 4, adjustment table 5, slotted hole 51, mounting beam 511, adjustment chuck 6, moving seat 7, rack 71, gear 8. Fastening screw 9, rib 52, flange body 81, lower cylinder 82, upper cylinder 83, bottom plate 10, lower installation part 101, upper installation part 512, clamper 61, strip-shaped horizontal plate 62, Front baffle 53 , rear baffle 54 , locking device 621 , positioning caliper 11 .

[0028] Such as Figure 1 to Figure 8 as shown,

[0029] A new type of double binding machine propulsion mechanism, including a bracket 1, a guide 2 is arranged on the bracket 1, a feed unit 3 can be operated automatically or manually through a rod, and a push un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com