Telescopic lock pin mechanism and automobile seat assembly

A telescopic, locking pin technology, applied in vehicle seats, vehicle parts, special positions of vehicles, etc., can solve problems such as accidental injury to passengers and poor appearance, and achieve the effect of ensuring safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific embodiments. It should be understood that the following examples are only used to illustrate the present invention but not to limit the scope of the present invention.

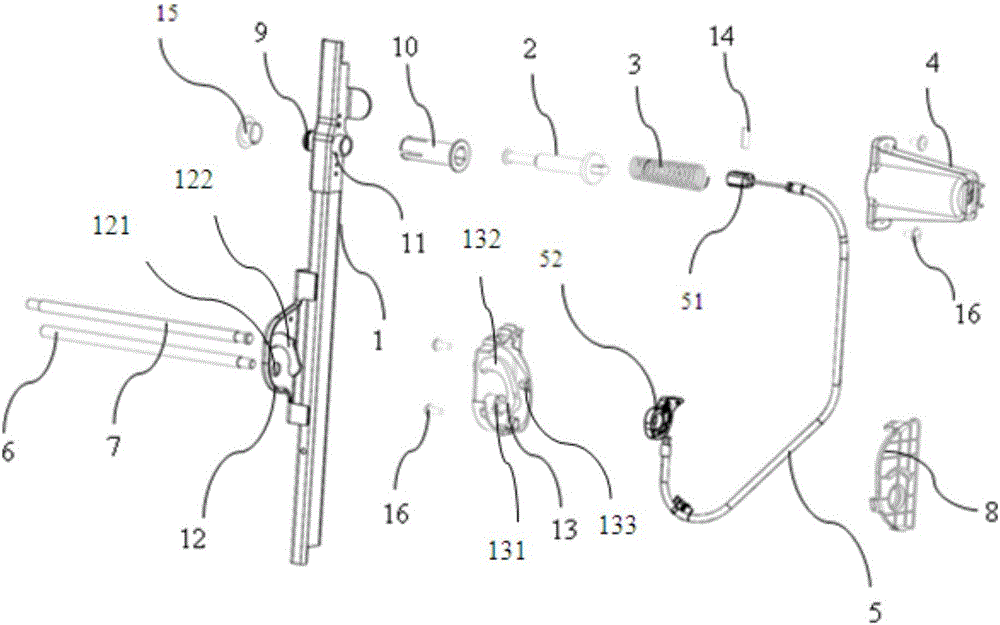

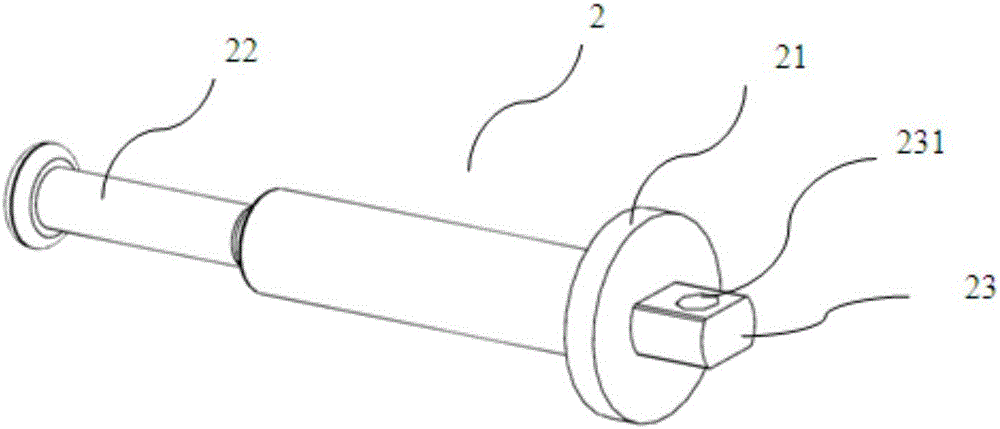

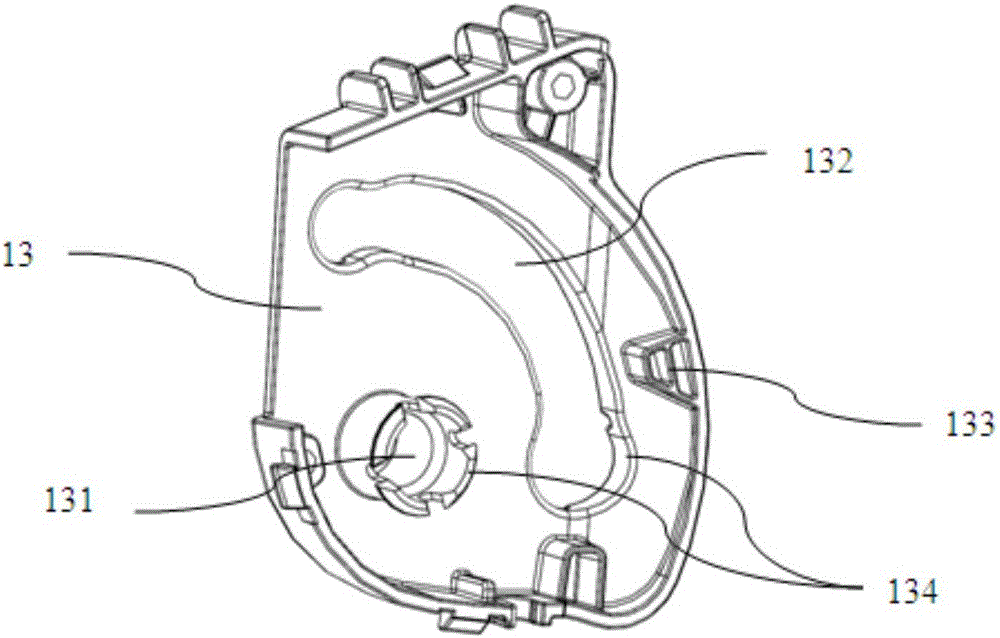

[0027] Such as Figure 1-9 As shown, a telescoping latch mechanism according to a preferred embodiment of the present invention is shown. The lock pin mechanism mainly includes: a skeleton 1, a lock pin 2, a spring 3, a fixed sleeve 4, a zipper assembly 5, a rotating shaft 6, and a limit shaft 7. Wherein, the frame 1 extends vertically, including an opening 11 at the top, and a shaft bracket 12 at the bottom. shaped hole 122, such as figure 2 As shown, the lock pin 2 has a substantially axially extending cylindrical body, wherein there is a radially extending flange 21 near one end, and locking rods 22 and connecting rods 23 respectively located on both sides of the flange 21, assembled , the locking rod 22 of the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com