Novel high performance sulfur dissolving agent and preparing method thereof

A sulfur-dissolving agent and high-performance technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of high cost, low solubility, and high cost, and achieve the improvement of sulfur-dissolving ability, increasing sulfur-dissolving speed, and improving Effect of Sulfur Dissolving Ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

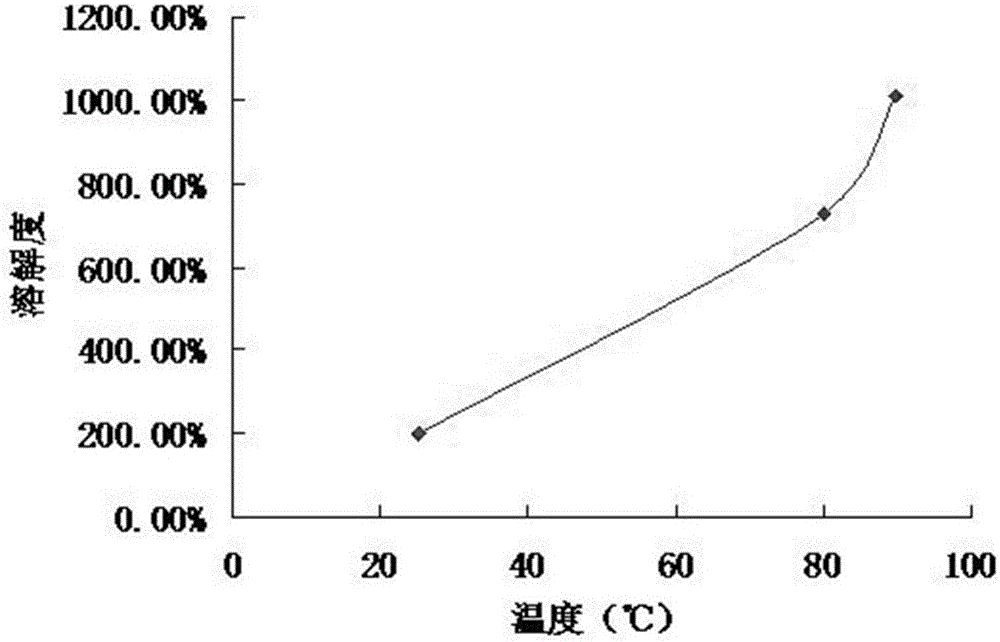

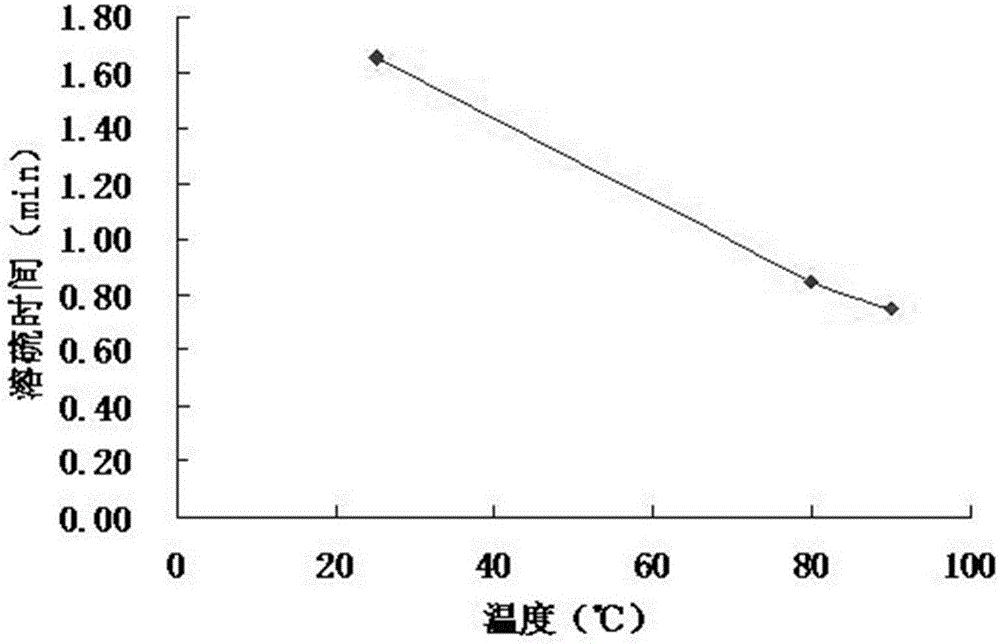

[0040] At room temperature (about 25°C), take 25 parts of the main agent (DMDS) and add it to the reaction vessel, then add 10 parts of the auxiliary solvent (DMSO), stir evenly, then add 0.125 parts of the catalyst sodium bisulfate, continue stirring evenly, and add the co-catalyst Add 0.25 parts of naphthalene, stir evenly without adding a phase transfer catalyst to obtain a sulfur dissolving agent, and conduct experiments on dissolving sublimated sulfur powder at 25°C, 80°C, and 90°C respectively, and the results are shown in the attached figure 1 . Respectively at 25°C, 80°C, and 90°C, dissolve half of the maximum amount of sulfur dissolved at each temperature, and conduct a sulfur dissolution time experiment. The results are shown in the attached figure 2 .

[0041] Experimental method and steps:

[0042] The experiment was carried out at atmospheric pressure and at a certain temperature. Sublimed sulfur (chemically pure) powder with a mass of M0 was added to a sulfur-...

Embodiment 2

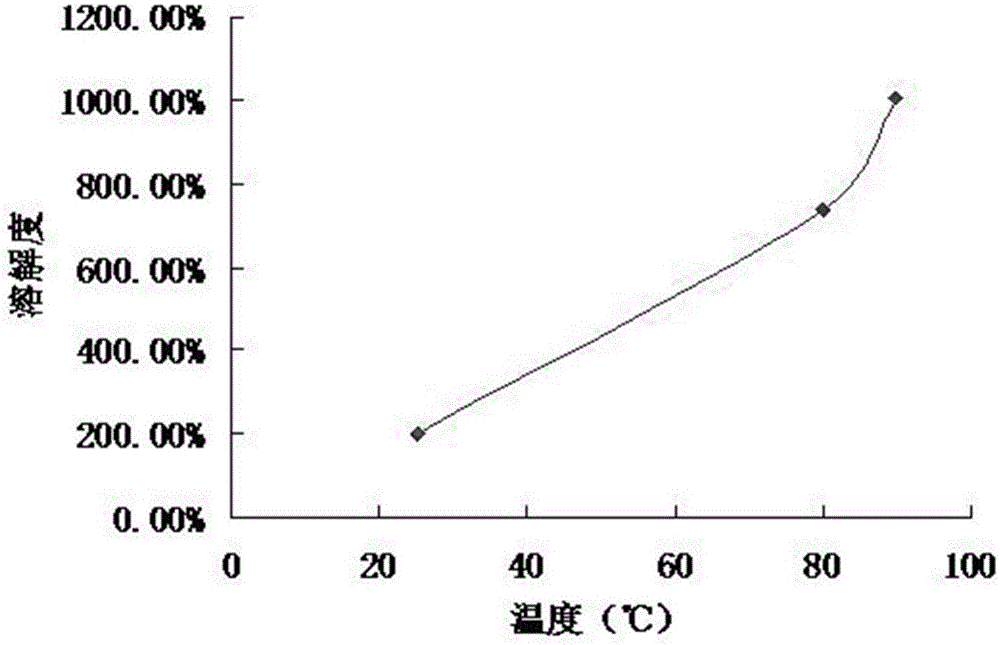

[0044] At room temperature (about 25°C), take 25 parts of the main agent (DMDS) and add it to the reaction vessel, then add 10 parts of the auxiliary solvent (DMSO), stir evenly, then add 0.125 parts of catalyst sodium bisulfate, continue stirring evenly, without adding Catalyst, add 0.25 part of phase transfer catalyst tetrabutylammonium chloride, stir evenly to obtain sulfur dissolving agent, carry out dissolving and sublimation sulfur powder experiments at 25°C, 80°C, and 90°C respectively, the results are shown in the attached image 3 . Respectively at 25°C, 80°C, and 90°C, dissolve half of the maximum amount of sulfur dissolved at each temperature, and conduct a sulfur dissolution time experiment. The results are shown in the attached Figure 4 .

[0045] Experimental method and step are identical with embodiment one;

Embodiment 3

[0047] At room temperature (about 25°C), take 25 parts of the main agent (DMDS) and add it to the reaction vessel, then add 10 parts of the auxiliary solvent (DMSO), stir evenly, then add 0.125 parts of the catalyst sodium bisulfate, continue stirring evenly, and add the co-catalyst 0.25 parts of naphthalene, continue to stir, then add 0.25 parts of phase transfer catalyst tetrabutylammonium chloride, stir evenly to obtain a sulfur dissolving agent, and carry out experiments on dissolving sublimated sulfur powder at 25°C, 80°C, and 90°C respectively. Figure 5 . Respectively at 25°C, 80°C, and 90°C, dissolve half of the maximum amount of sulfur dissolved at each temperature, and conduct a sulfur dissolution time experiment. The results are shown in the attached Figure 6 .

[0048] Experimental method and step are identical with embodiment one;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com