Variable control device of hydraulic pump and control method thereof

A technology of variable control and hydraulic pumps, which is applied in the direction of fluid pressure actuators, servo motors, servo motor components, etc., can solve problems such as low efficiency, high heat generation, and inability to comprehensively consider pressure, flow, power, and efficiency performance. Achieve good system stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

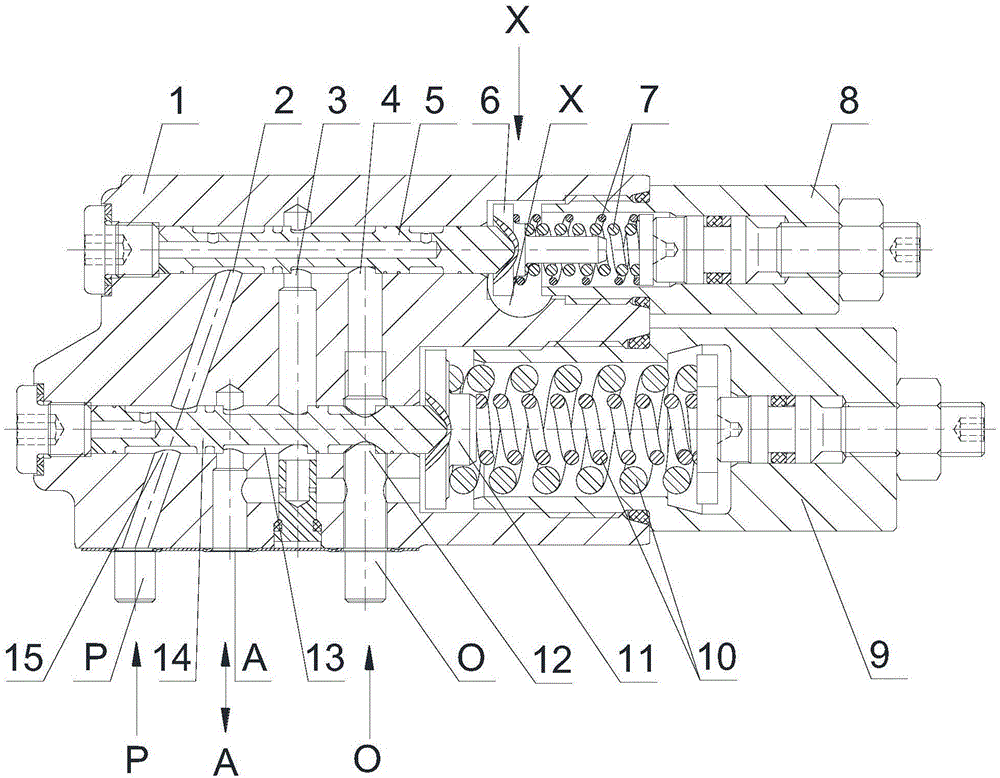

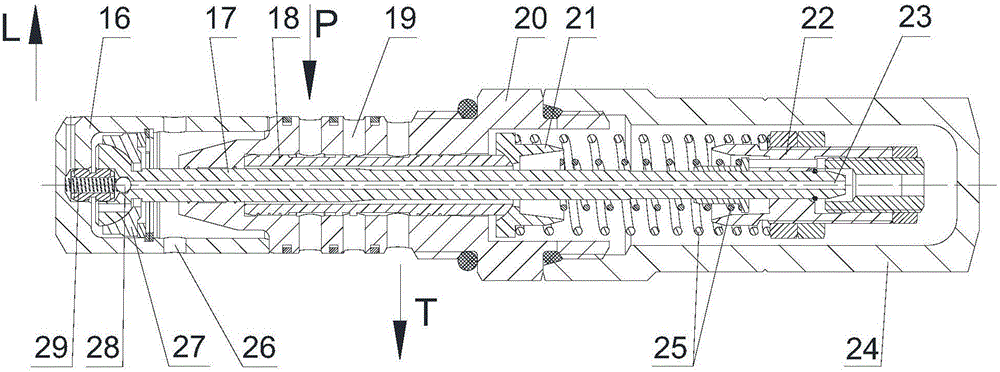

[0022] see Figure 1-3 , the present invention includes: valve body 1, first left working port 2, first middle working port 3, first right working port 4, first valve core 5, first spring seat 6, first spring 7, first valve Cover 8, second valve cover 9, second spring 10, second spring seat 11, second right working port 12, second middle working port 13, second spool 14, second left working port 15, regulating piston 16 , piston rod 17, spool 18, lateral middle hole 19, piston guide sleeve 20, spring seat 21, adjustment screw 22, hydraulic oil through hole 23, protective cap 24, reset adjustment spring 25, high-pressure oil inlet 26, spherical surface Seat 27, steel ball 28, check valve spring 29.

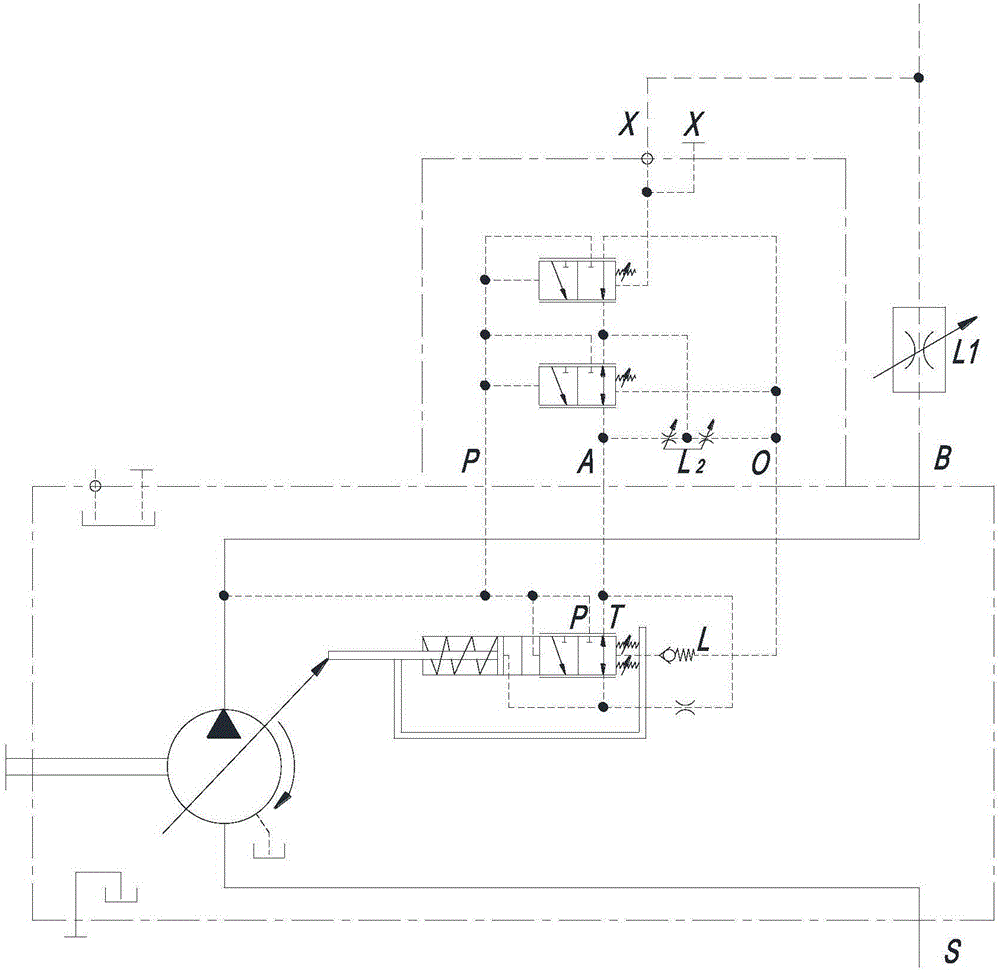

[0023] figure 1 The hydraulic control princ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com