A belt conveyor tensioning system

A belt conveyor and tensioning system technology, applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of easy shock, motor suction, and inability to use winches in emergency, and achieves the possibility of lifting. The effect of controllability and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following is a specific embodiment of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

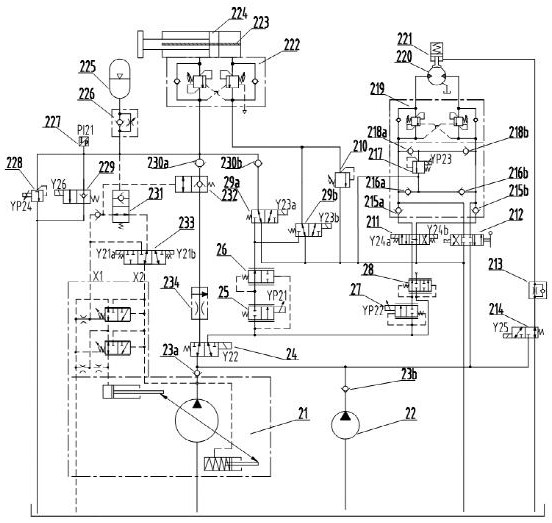

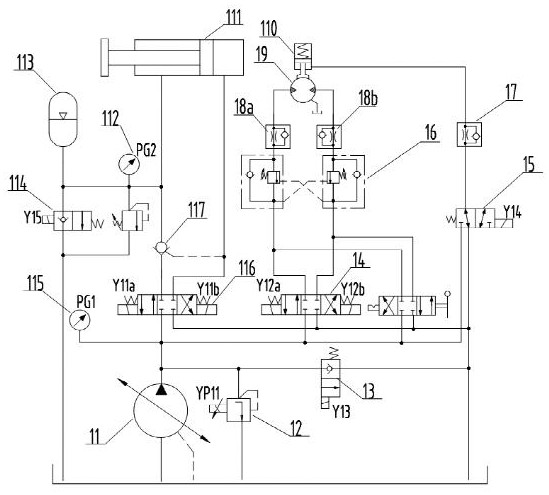

[0046] combine figure 1 As shown, a belt conveyor tensioning system, the oil outlet of the constant pressure pump 21 is connected to the first one-way valve I23a, and the oil outlet of the emergency pump 22 is connected to the second one-way valve I23b. The first one-way valve I23a and the second one-way valve I23b are respectively connected to the two-position three-way valve I24, the mechanical three-position four-way valve 212 and the two-position three-way valve III214 after confluence.

[0047] The two-position three-way valve I24 is connected to the speed control valve 234, the two-position two-way proportional valve I25 and the two-position two-way proportional valve II27;

[0048] The speed regulating valve 234 is connected to the hydraulically controlled two-position two-way valve II232, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com