Connecting structure of pipe shell type heat exchanger pipe plate and heat exchange pipe

A heat exchanger and connection structure technology, which is applied in the field of connection structure between tube sheets and heat exchange tubes of shell-and-tube heat exchangers, can solve problems such as difficulty in ensuring connection strength and sealing between tube sheets and heat exchange tubes, and prevent Other failure modes, improving sealing performance, and ensuring the effect of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

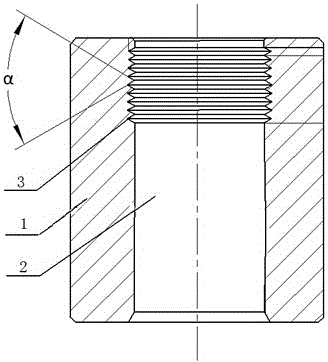

[0023] Such as figure 1 The connection structure between the tube plate and the heat exchange tube of a shell-and-tube heat exchanger shown includes a tube plate 1, a heat exchange tube hole 2 is provided on the tube plate 1, and a heat exchange tube hole 2 is provided on the inner wall of the heat exchange tube hole 2 There is a group of sealing groove group 3. The included angle α between the sides of two adjacent sealing grooves in the sealing groove group 3 is 30° to 60°. The sealing groove group 3 includes 3 to 12 sealing grooves.

Embodiment 2

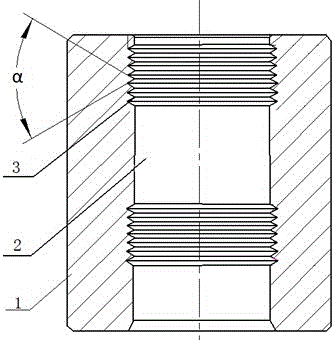

[0025] Such as figure 2 The connection structure between the tube plate and the heat exchange tube of a shell-and-tube heat exchanger shown includes a tube plate 1, a heat exchange tube hole 2 is provided on the tube plate 1, and a heat exchange tube hole 2 is provided on the inner wall of the heat exchange tube hole 2 There are two sets of seal groove sets 3 . The included angle α between the sides of two adjacent sealing grooves in the sealing groove group 3 is 30° to 60°. The sealing groove group 3 includes 3 to 12 sealing grooves.

[0026] In the present invention, at least one group of sealing grooves is arranged on the inner wall of the heat exchange tube hole on the tube plate, so that the connection mode between the tube plate and the heat exchange tube includes not only the expansion joint between the seal groove group and the outer wall of the heat exchange tube, but also includes The portion on the inner wall of the tube hole of the heat exchange tube that is not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com