Compound control method and system based on plug-in type rapid repetitive controller

A repetitive controller and composite control technology, applied in general control systems, control/regulation systems, adaptive control, etc., can solve the problems of slow dynamic response of repetitive controllers, slow dynamic response, and inability to work with sub-harmonics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further explained below in conjunction with the drawings.

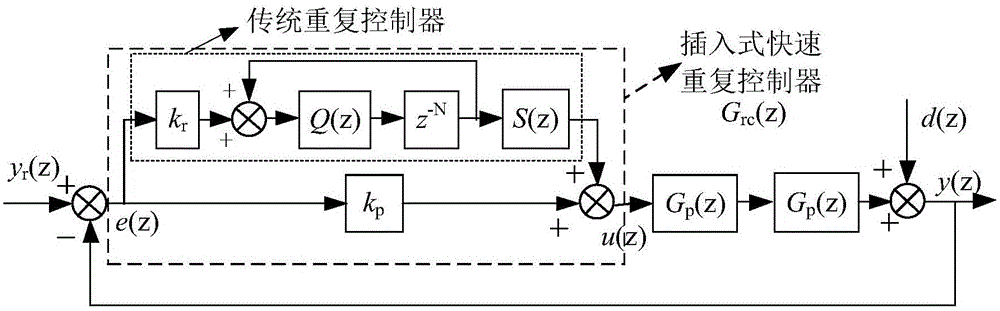

[0049] Such as figure 1 As shown, the composite control system based on the plug-in fast repeat controller of the present invention includes a plug-in fast repeat controller, a plug-in fast repeat controller feedforward gain module, a repeat control gain module, a positive feedback gain module, and two additions Loop, internal model constant module or internal model low-pass filter, internal model delay module, compensator module, the two addition loops are the first addition loop and the second addition loop, in which the input of the repeated control gain module is used as The input terminal of the repeat controller and the input terminal of the feedforward gain module, the output terminal of the repeat control gain module is connected to the input terminal of the first addition loop, and the output terminal of the first addition loop is connected to the internal modulus module of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com