Doughnut dough, frozen doughnut dough, doughnut, and process for producing doughnut

A manufacturing method and technology for doughnuts, which are applied to doughnut doughnuts of doughnuts, and the manufacturing field of doughnuts, can solve complicated manufacturing processes, inability to provide doughnuts stably, deviation of green bodies, etc. problem, to achieve the effect of simple and stable manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

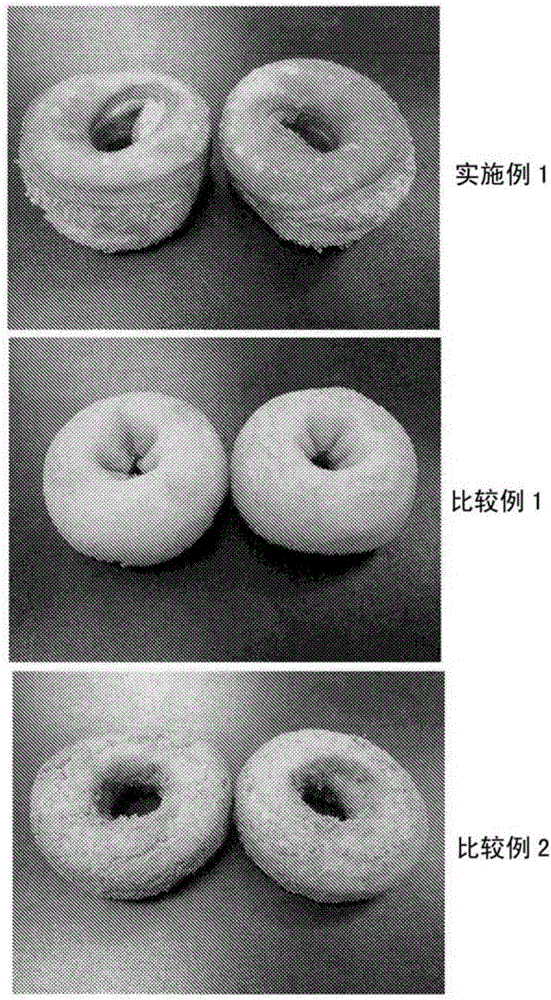

[0083] In Experimental Example 1, it was investigated which kind of donuts manufactured by the technique of the present invention was classified into various donuts manufactured by a conventional manufacturing method.

[0084] (1) Production of donuts

Embodiment 1

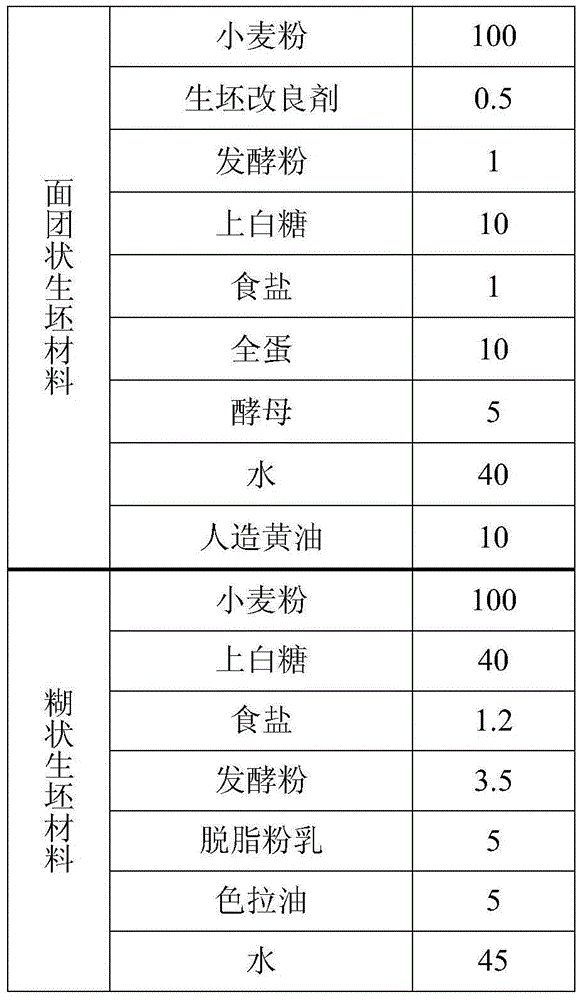

[0086] The materials of the dough-like dough shown in Table 1 below were kneaded to produce the dough-like dough. Moreover, the materials of the paste-form green body shown in following Table 1 were mixed, and the paste-form green body was produced. The prepared dough-like dough and paste-like dough were stacked in 16 layers at a weight ratio of 60:40 to produce donut dough. After demolding this green donut body, it was deep-fried at 180° C. for 3 minutes (dipping in oil: submerged frying) to manufacture donuts.

Embodiment 2

[0088] After demolding the raw dough dough produced by the method similar to Example 1, it was frozen at -18 degreeC or less, and the frozen doughnut dough was produced. The produced frozen donut raw material was preserved at -18 degreeC for 4 weeks, and then it was deep-fried at 180 degreeC for 4 minutes without thawing (dipping in oil: deep-frying), and the donut was manufactured.

[0089] [Table 1]

[0090] (g)

[0091]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com