Seamless pipe of martensitic stainless steel for oil well pipe and process for producing same

A technology of seamless steel pipe and manufacturing method, which is applied in the field of martensitic stainless steel seamless steel pipe for oil well pipes, can solve problems such as the increase of steel pipe characteristic deviation, and achieve the effect of less increase in yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

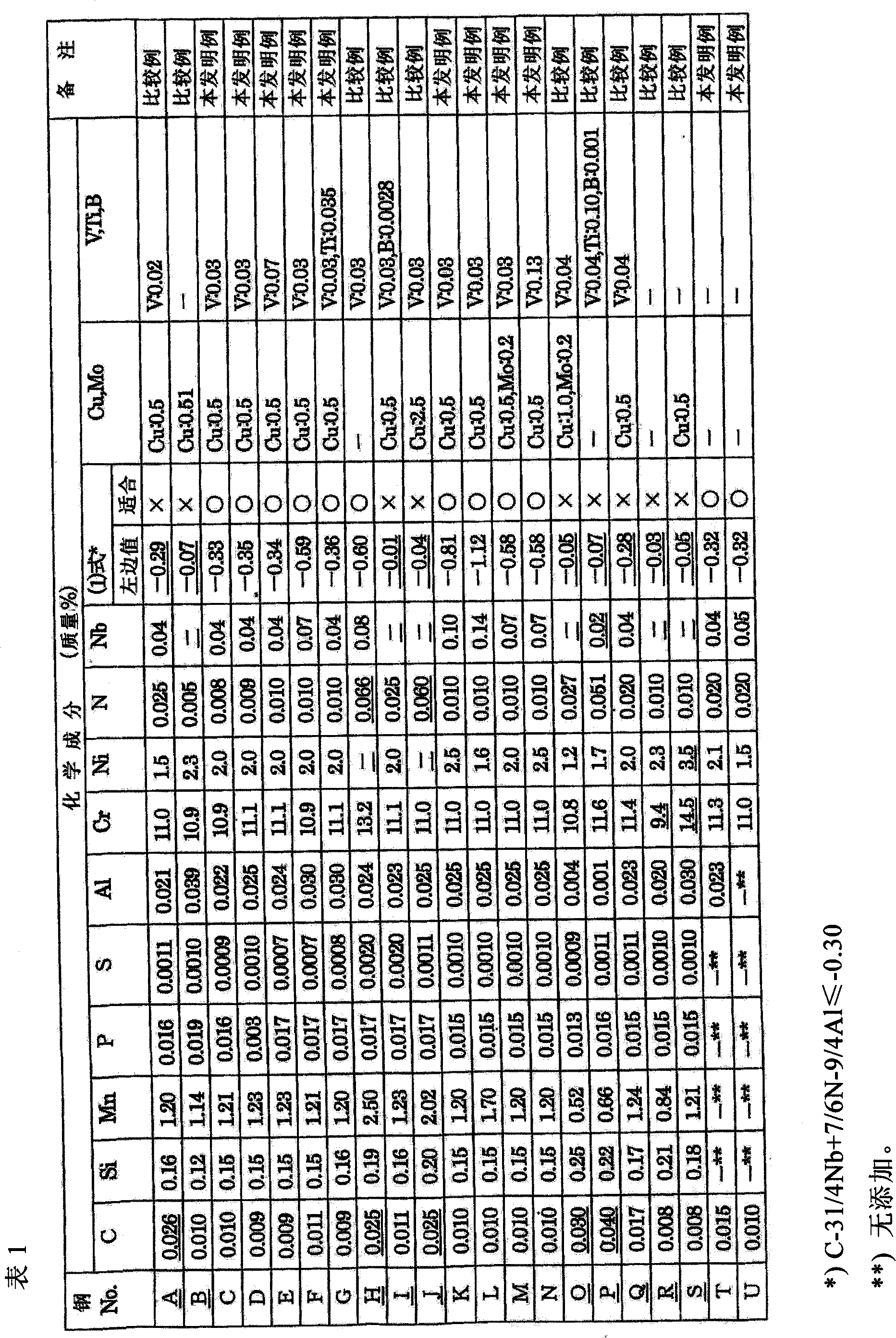

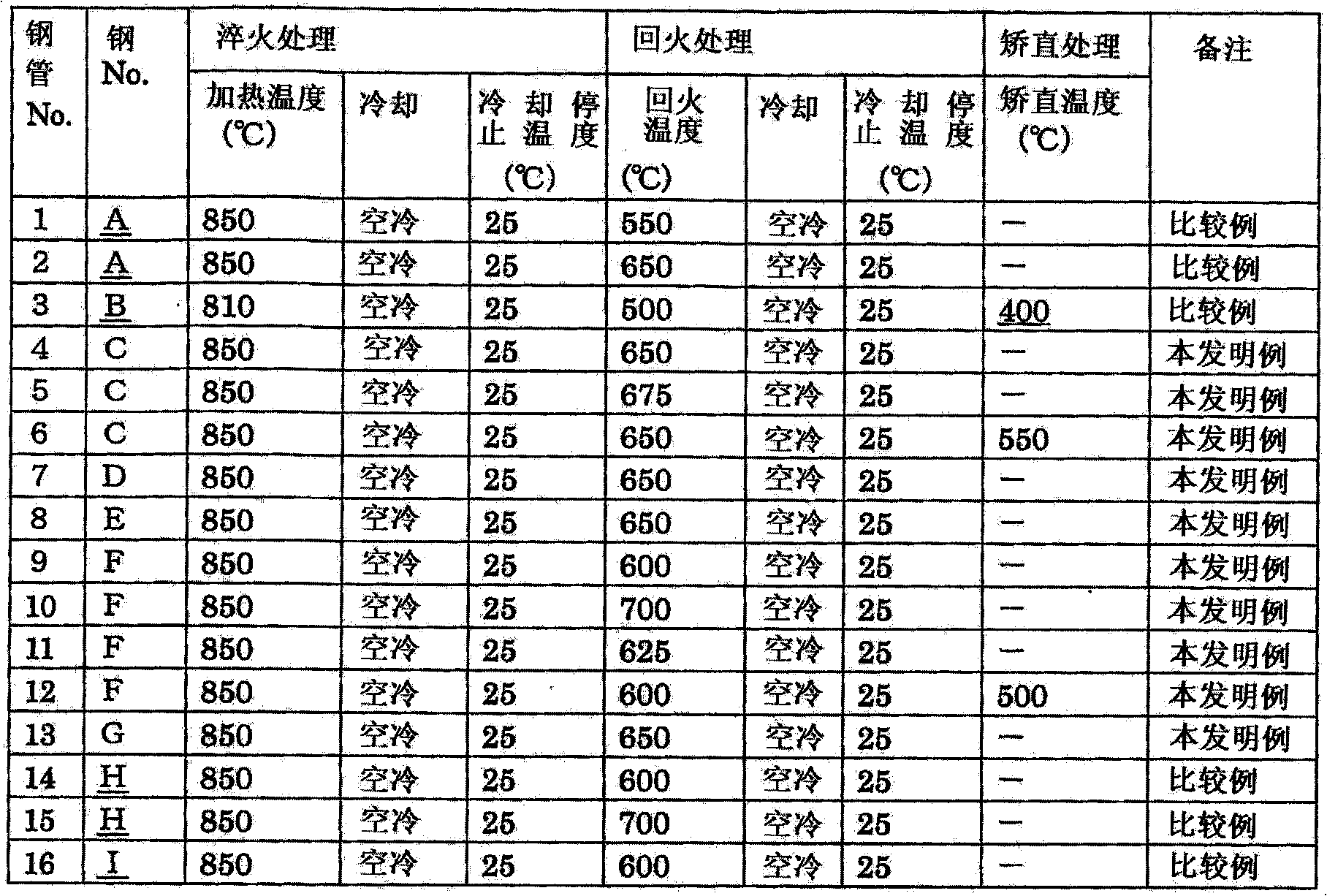

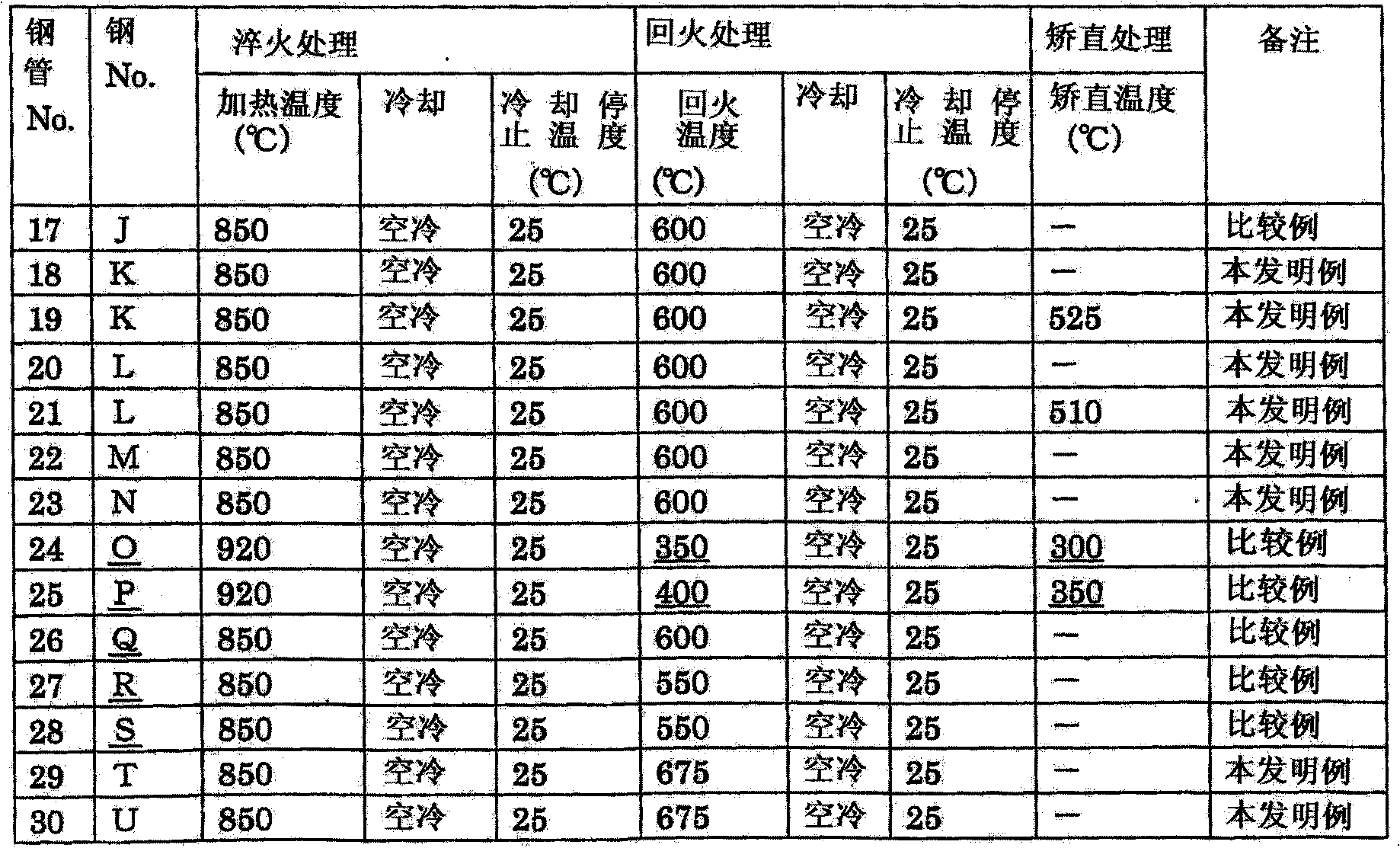

[0084] After degassing the molten steel with the composition shown in Table 1, it was cast into a billet (size: 207mmΦ) by continuous casting to produce a steel pipe material. These steel pipe materials were heated, hot-processed using a Mannesmann method manufacturing process to manufacture pipes, and then air-cooled to obtain seamless steel pipes (outer diameter 177.8 mmΦ×wall thickness 12.65 mm).

[0085] A test material (steel pipe) was cut from the obtained seamless steel pipe, and the test material (steel pipe) was quenched and tempered under the conditions shown in Table 2 and Table 3, or further subjected to straightening treatment.

[0086] A test piece for electrolytic extraction was cut out from a test material (steel pipe) subjected to quenching treatment and tempering treatment, or further subjected to straightening treatment. Using the cut test piece for electrolytic extraction, the amount of Nb contained in the obtained electrolytic residue was determined using ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com