fuel injection system

A fuel injection system and fuel technology, applied in fuel injection pumps, fuel injection devices, fuel injection control, etc., can solve problems such as noise and achieve the effect of reducing torque peaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

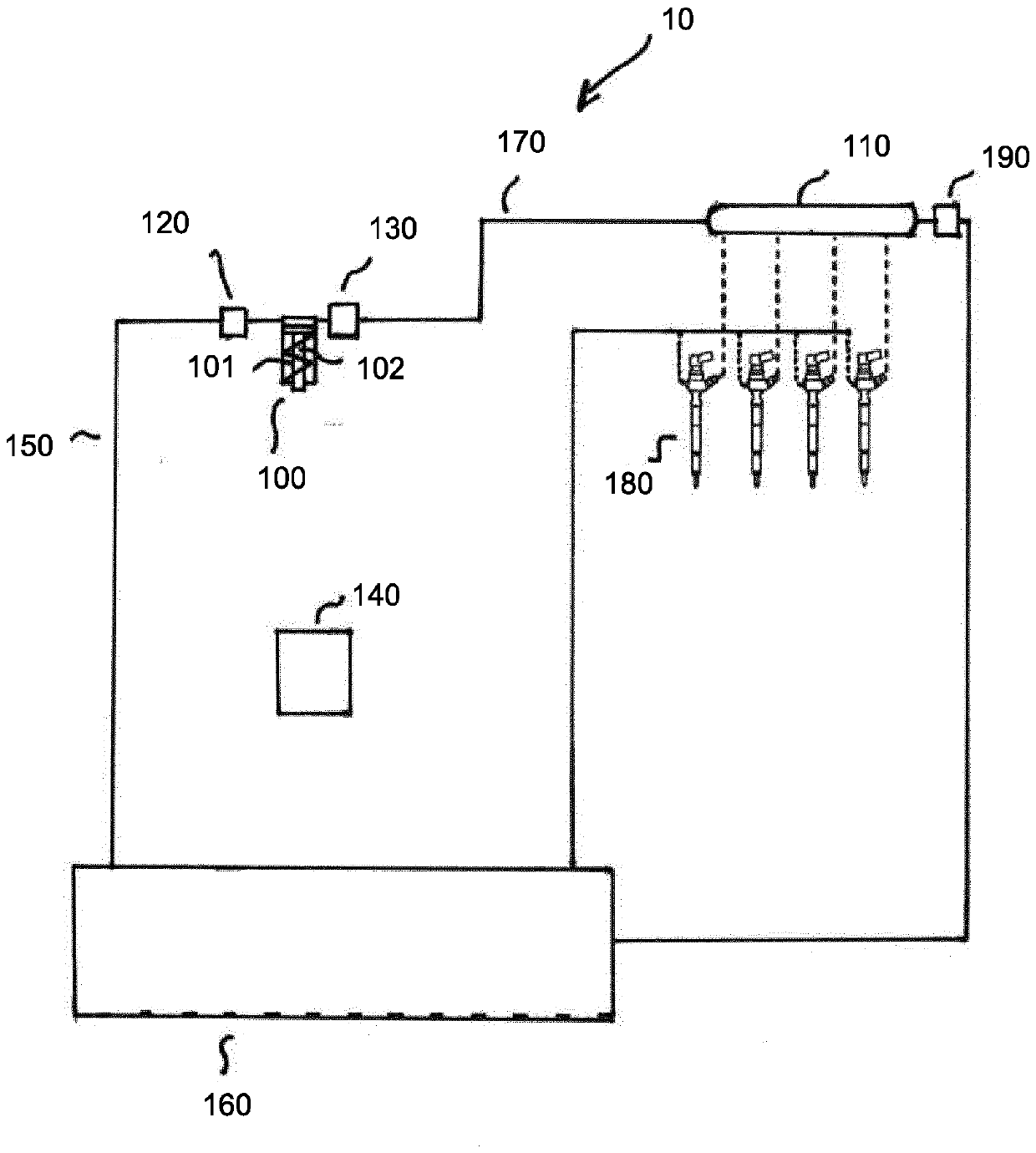

[0018] figure 1 An exemplary embodiment of a fuel injection system 10 is shown, which can be designed, for example, as a common rail fuel injection system. The fuel injection system includes a high-pressure pump 100 with a pump working space 101 for compressing fuel. The high-pressure pump has a pump piston 102 which is supported on the tappet by means of a spring. A tappet is movably disposed in the tappet guide. In order to compress the fuel in the pump working space, the pump piston performs a complete up and down movement in the pump working space 101 during each pump stroke. To move the pump piston, the tappet is coupled to the drive shaft. The drive shaft can have one or more cams on which the tappet rests via rollers. During rotation of the drive shaft, the rotational motion of the shaft is converted by the cam into reciprocating motion of the piston.

[0019] The fuel injection system 10 further has a pressure accumulator 110 for supplying fuel for injection into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com