Actuation of fuel injectors for multiple injections

A technology of fuel injectors and drives, which is applied in the direction of fuel injection control, combustion engines, machines/engines, etc. It can solve problems such as not considering the influence of relative quantity difference, and achieve the effect of precise injection quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] It is to be noted that the embodiments described hereinafter represent only a limited selection of possible embodiment variants of the invention.

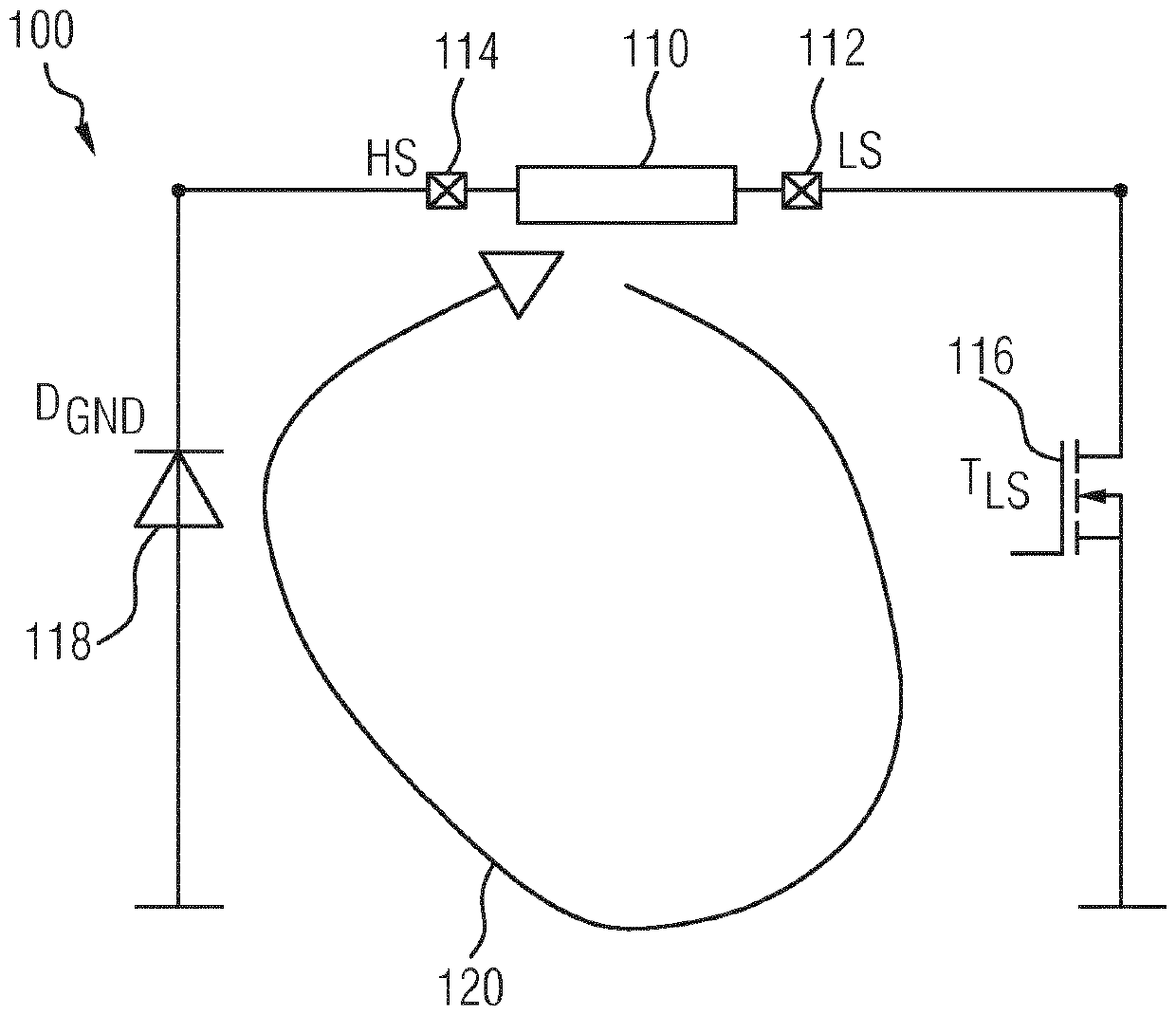

[0036] figure 1 A circuit diagram 100 shows a portion of a circuit for actuating a fuel injector 110 according to one embodiment. Fuel injector 110 has terminals 112 (low side LS) and 114 (high side HS). Terminal 112 is connected to transistor 116 (low side transistor T LS ), and can therefore be grounded. terminal 114 through diode 118 (freewheeling diode D GND ) to ground.

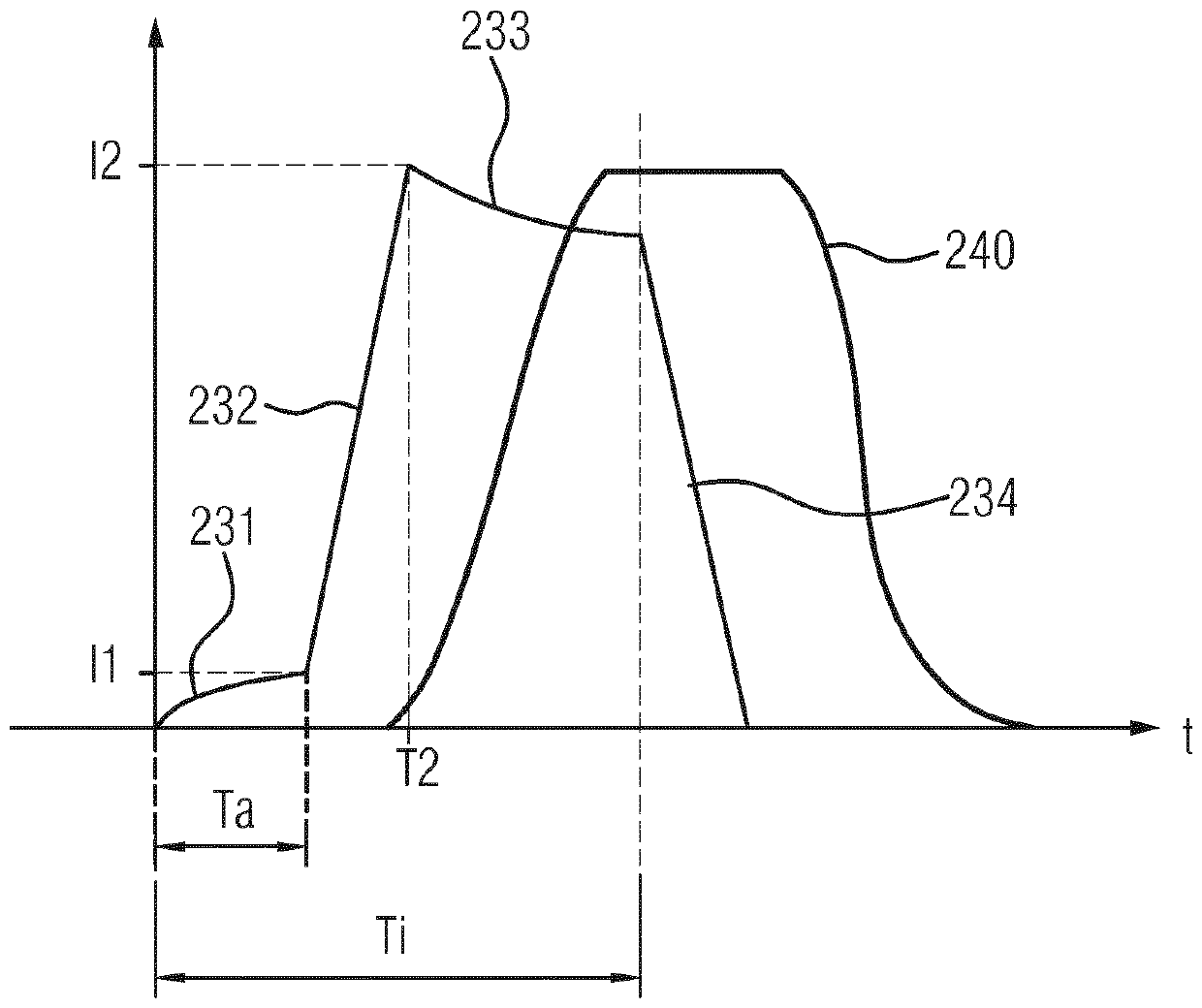

[0037] figure 2 Graph 201 shows exemplary time current curves 231 - 234 according to one embodiment. Diagram 201 also shows the temporal profile of fuel quantity introduction 240 .

[0038] The following will refer to figure 1 and 2The actuation of the fuel injector according to the present invention will be described. In operation, transistor 116 is actuated so that terminal 112 is grounded. If there is residual magnetization in fuel injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com