Control system and control method of oil-air dual-fuel engine supplied by mechanical pump

A dual-fuel engine and control system technology, applied in engine control, machine/engine, mechanical equipment, etc., can solve problems such as increased fuel consumption, exhaust emissions, poor stability, and impact on engine life, so as to improve stability and reliability performance, improving accuracy, and overcoming accuracy problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

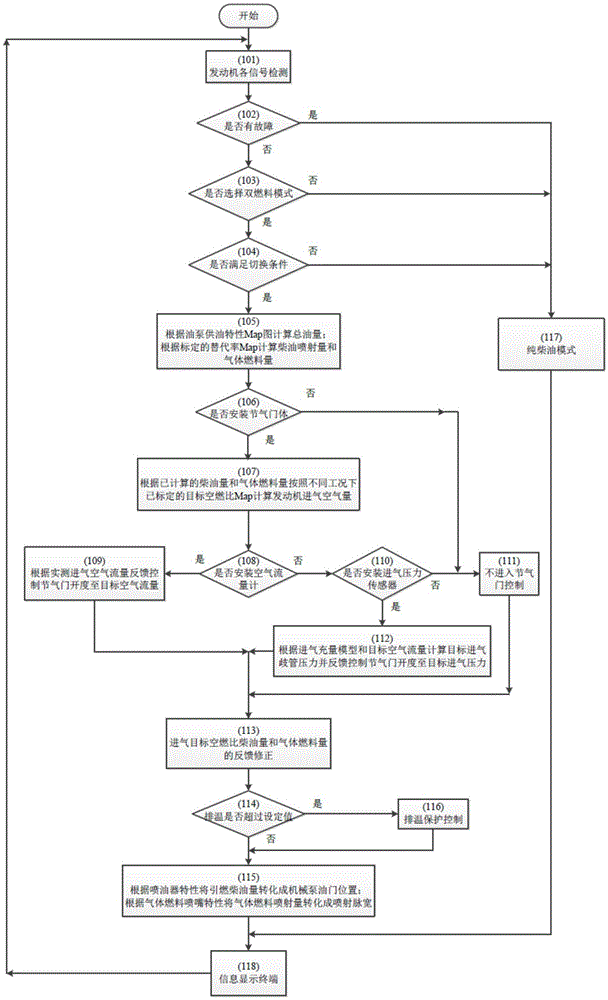

[0041] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

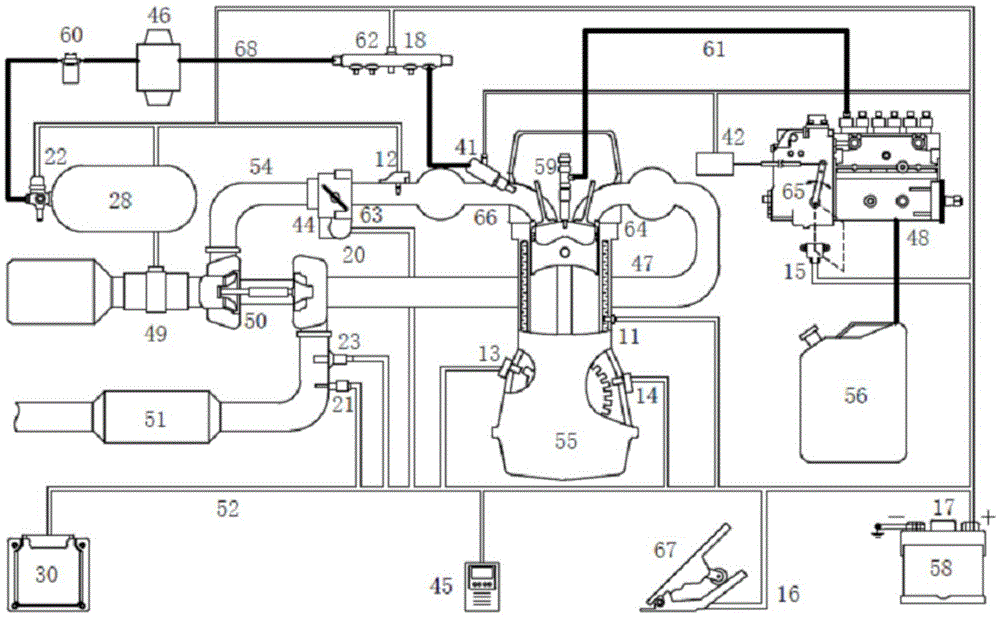

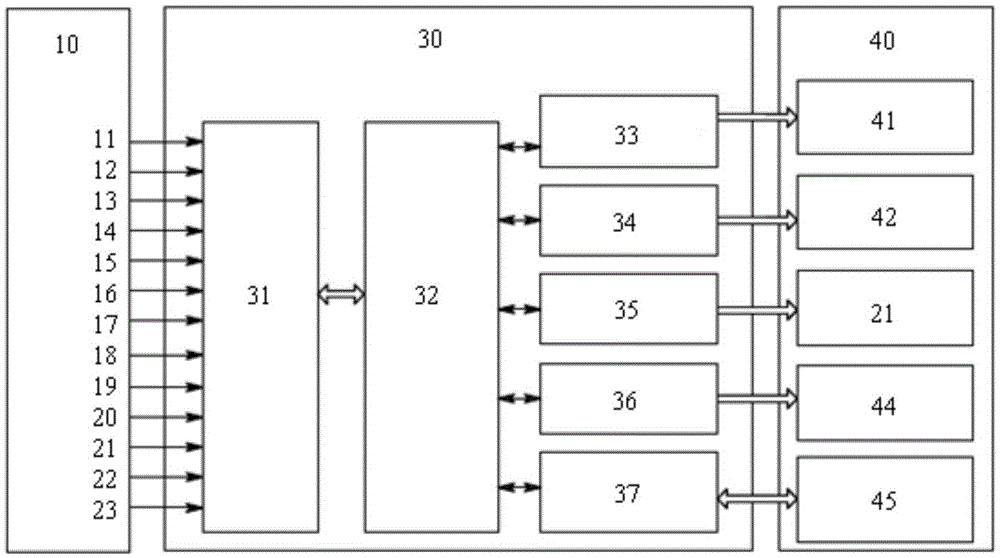

[0042] refer to figure 1 and figure 2 , the control system of the oil-gas dual-fuel engine supplied by the mechanical pump provided by the present invention includes a mechanical high-pressure oil pump 48 implementing diesel quantity control and high-pressure injection, a gas electronically controlled injection system and an oil-gas dual-fuel electronically controlled system.

[0043] The mechanical high-pressure oil pump 48 is installed on the engine body 55. The mechanical high-pressure oil pump 48 completes the metering control of the amount of diesel oil and the formation of the high pressure required for high-pressure injection. The metered and pressurized diesel oil reaches the injection nozzle through the high-pressure oil pipe 61. The oiler (nozzle) 59 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com