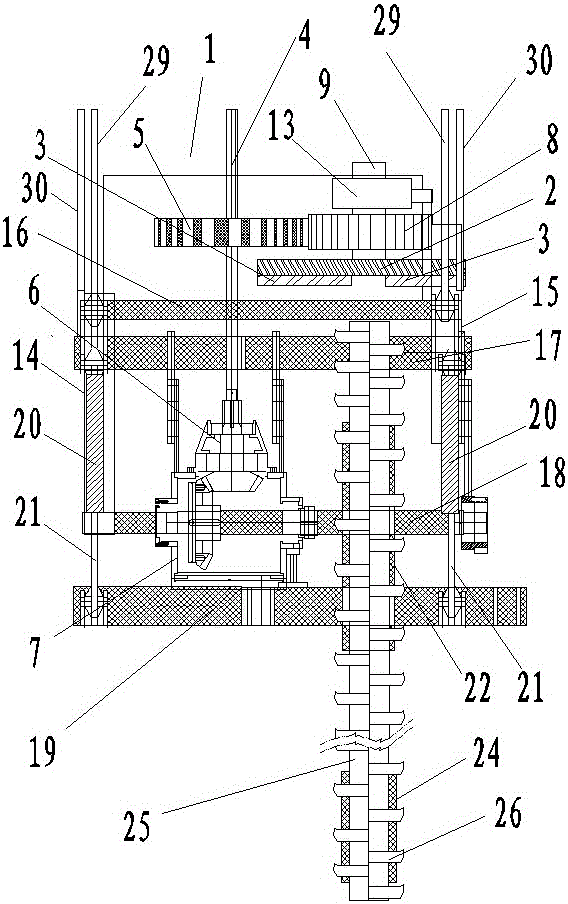

A New Type Disc Soil Divider

A ditching machine and disc-type technology, which is applied in the direction of excavation/covering trenches, planting methods, applications, etc., can solve the problems that affect the ditching efficiency of the ditching machine and the long throwing distance, and achieve novel structure and return Uniform force on the soil, easy to operate and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

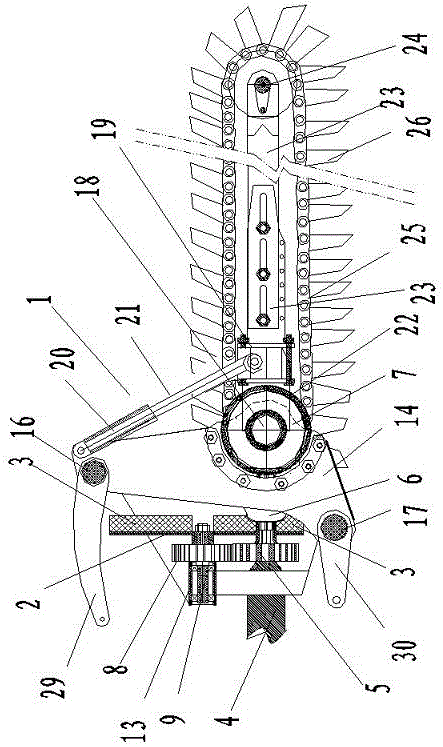

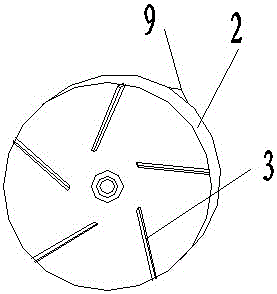

[0042] Example 2. Such as Figure 4 As shown, the only difference between this embodiment and Embodiment 1 is that the power transmission system includes the power take-off shaft 4 of the tractor, and the power take-off shaft 4 of the tractor is provided with a drive wheel; the front end of the power take-off shaft 4 is provided with a universal joint 6 , the universal joint 6 is connected with the gearbox 7 of the ditching tool system; the rotating shaft 9 of the soil dividing plate is installed on the frame body 1 through a bearing 13, and a transmission wheel 11 is arranged on the rotating shaft 9 of the dividing soil plate, and the dividing soil plate The transmission wheel 11 on the rotary shaft 9 of the tractor is connected with the transmission wheel 10 on the power output shaft 4 of the tractor by a belt 12 or a chain.

Embodiment 3

[0043] Example 3. Such as Figure 5 As shown, the only difference between this embodiment and Embodiment 1 is that the left and right ends of the support rod connecting plate 19 are provided with vertical plates 28, and the output shaft 21 of the hydraulic cylinder at the top of the left vertical plate 14 is connected with the support rod connecting plate 19. The vertical plate 28 at the left end is hinged, and the output shaft 21 of the hydraulic oil cylinder at the top of the right vertical plate 15 is hinged with the vertical plate at the right end of the support rod connecting plate 19 . The left and right ends of the support rod connecting plate 19 are provided with vertical plates 28, which increases the control range of the hydraulic cylinder to the supporting rod connecting plate 19 along the power output shaft 18 of the ditching tool.

Embodiment 4

[0044] Example 4. Such as Image 6 As shown, the only difference between this embodiment and Embodiment 1 is: the left and right ends of the ditching tool power output shaft 18 are hinged with connecting plates 27; The left end of 19 is hinged, and the connecting plate of the right-hand side of ditching cutter power output shaft 18 is hinged with the right-hand side of support bar connecting plate 19. With this structure, the rigidity of the device is improved.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap