A fully automatic machine-packed carton high-efficiency production linkage equipment

A high-efficiency and linkage technology, applied in packaging, papermaking, transportation and packaging, etc., can solve the problems of low degree of mechanization of production equipment, large area of production site, unsatisfactory cardboard waste removal effect, etc., to achieve automatic inventory and save money. The effect of increased labor, dedusting, and inventory efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

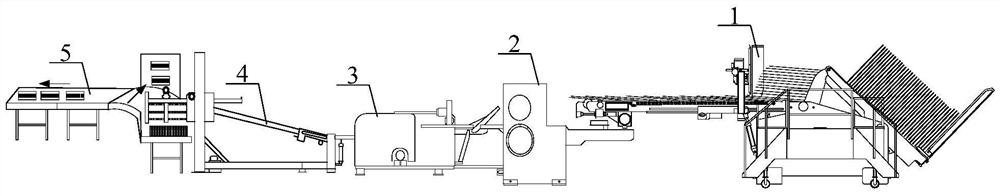

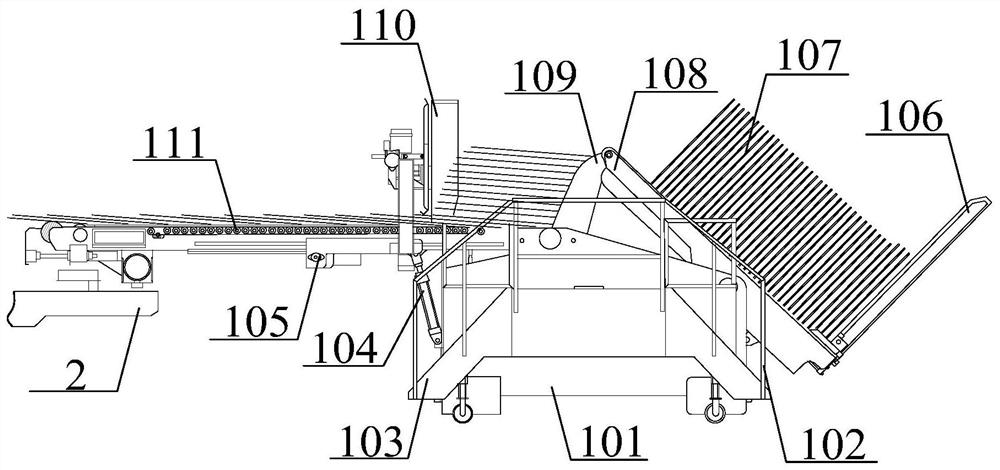

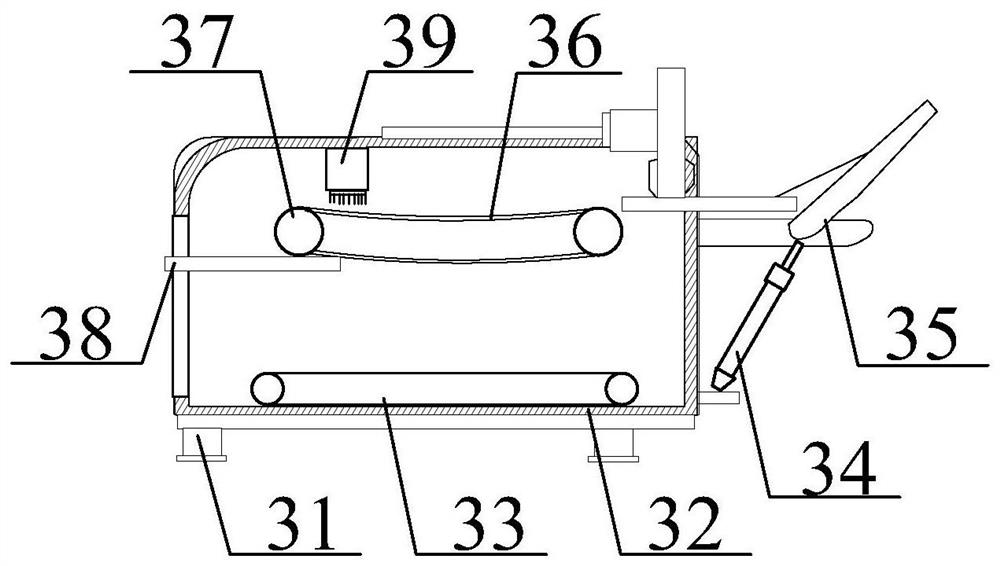

[0025] Such as Figure 1-4 As shown, the present invention provides a technical solution: a fully automatic machine-packed carton high-efficiency production linkage equipment, including an automatic paper feeder, a die-cutting machine, an oscillating dandruff removal machine, a point collector and a delivery roller table. The automatic paper feeder described above is arranged on the right end of the die-cutting machine, and the feeding roller in the automatic paper feeder is positioned at the upper end on the right side of the die-cutting machine, and is higher than 20-30cm; the left end of the die-cutting machine is provided with a shock Chip removal machine; the cardboard of the vibration chip removal machine is flush with the discharge port of the die-cutting machine; the point collector is located on the left side of the vibration chip removal machine, wherein the height of the adjustment plate and the feeding plate are consistent; the The above-mentioned paper delivery de...

Embodiment 2

[0027]A fully automatic machine-packed carton high-efficiency production linkage equipment, including an automatic paper feeder, a die-cutting machine, an oscillating dandruff remover, a point collector, and a paper delivery conveyor roller table. The automatic paper feeder is set on the die-cutting machine the right end of the die-cutting machine, and the feeding roller in the automatic paper feeder is located at the upper end of the right side of the die-cutting machine, and is 20-30 cm higher; the left end of the die-cutting machine is provided with a vibrating chip removal machine; The cardboard is flush with the discharge port of the die-cutting machine; the point collector is located on the left side of the oscillating chip removal machine, and the height of the adjustment plate and the feeding plate are the same; the delivery roller table is set in an arc shape as a whole , is set on the left side of the point collector, and is located below the discharge port, to better...

Embodiment 3

[0030] A fully automatic machine-packed carton high-efficiency production linkage equipment, including an automatic paper feeder, a die-cutting machine, an oscillating dandruff remover, a point collector, and a paper delivery conveyor roller table. The automatic paper feeder is set on the die-cutting machine the right end of the die-cutting machine, and the feeding roller in the automatic paper feeder is located at the upper end of the right side of the die-cutting machine, and is 20-30 cm higher; the left end of the die-cutting machine is provided with a vibrating chip removal machine; The cardboard is flush with the discharge port of the die-cutting machine; the point collector is located on the left side of the oscillating chip removal machine, and the height of the adjustment plate and the feeding plate are the same; the delivery roller table is set in an arc shape as a whole , is set on the left side of the point collector, and is located below the discharge port, to bette...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap