Bending machine

A bending machine and frame technology, applied in the field of bending machines, can solve problems such as inconvenient adjustment of bending angles, and achieve the effects of saving man-hours and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing.

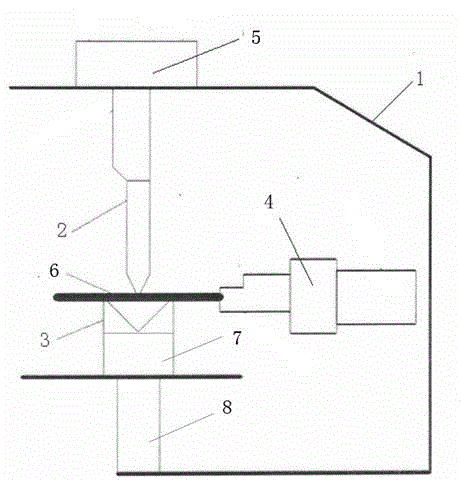

[0011] The structure of the present invention is as figure 1 As shown, including a frame 1, a power mechanism 5 is installed on the top of the frame 1, and the power mechanism 5 is connected with the upper mold 2 in the frame 1, and the corresponding position below the upper mold 2 is provided with a lower mold 3, and the lower mold 3 is installed on the machine. At the bottom of the frame 1, a feeding device 4 is provided in the horizontal direction between the upper mold 2 and the lower mold 3. The lower mold 3 is a triangle with two opposite hypotenuses, and a drive motor 7 is installed below the lower mold 3 to drive The motor 7 drives the triangular movement of the lower mold 3 to adjust the angle between the triangles, and the lower part of the driving motor 7 is connected with the frame 1 through the telescopic rod 8 .

[0012] During work, first according to workpi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com