An automatic ranging, leveling and shearing production line

A production line and leveling technology, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve problems such as inaccurate size measurement, low secondary leveling accuracy, and poor consistency, so as to improve precision and accuracy and avoid damage Good effect with maintenance, stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

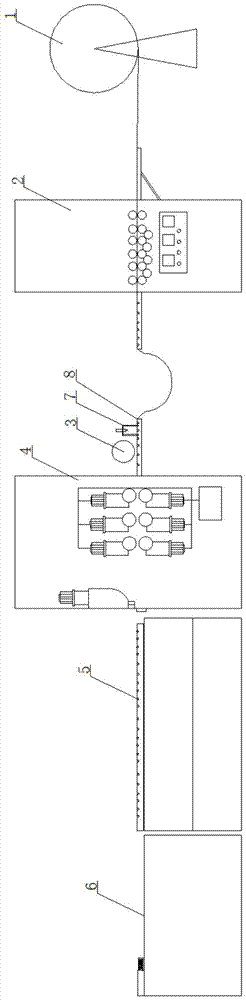

[0038] Such as figure 1 As shown, this scheme includes an unwinding machine 1, a primary leveling machine 2, a distance measuring roller 3, a conveyor belt 5, a receiving machine 6 and a transition conveyor belt 8, and also includes a secondary leveling and shearing machine 4 and a probe module 7. The unwinding machine 1, the primary leveling machine 2, the transition conveyor belt 8, the secondary leveling machine 4, the conveyor belt 5 and the material receiving machine 6 are connected in sequence, and the probe module 7 and the distance measuring roller 3 are sequentially arranged on the transition conveyor belt 8 above;

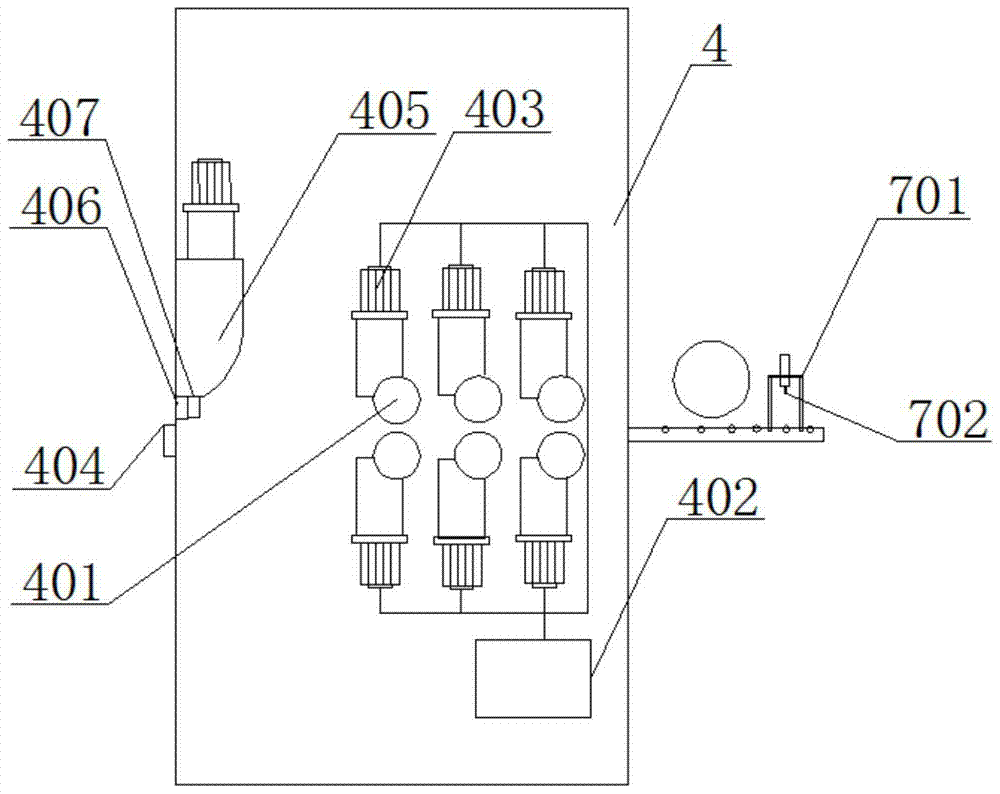

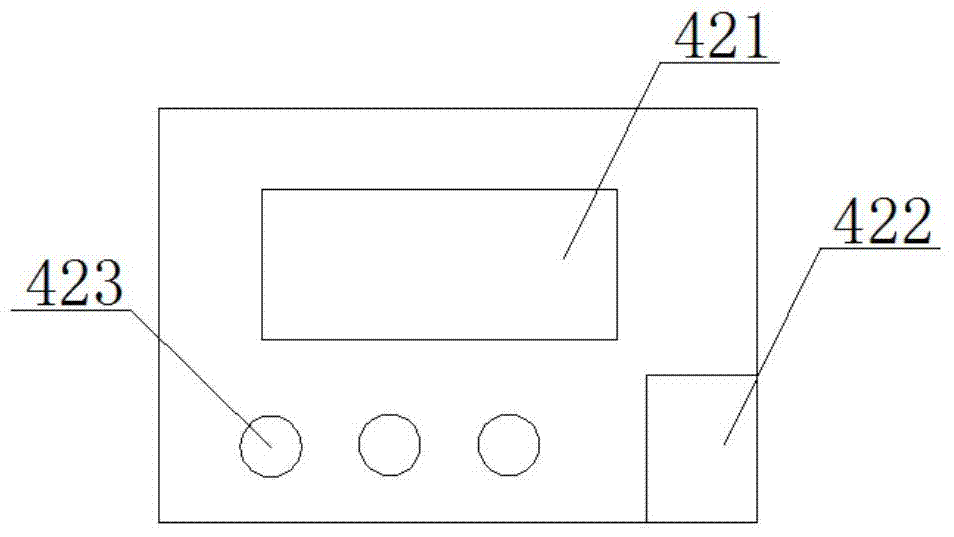

[0039] Such as figure 2 As shown, the secondary leveling and shearing machine 4 includes a leveling roller 401, a control box 402, a drive motor 403, a lower knife 404, a slider 405, an upper knife 406 and a vertical distance measuring device 407, the described The bottom of the slide block 405 facing the entrance of the shearing machine is arc-shaped....

Embodiment 2

[0048] Such as figure 1 As shown, this scheme includes an unwinding machine 1, a primary leveling machine 2, a distance measuring roller 3, a conveyor belt 5, a receiving machine 6 and a transition conveyor belt 8, and also includes a secondary leveling and shearing machine 4 and a probe module 7. The unwinding machine 1, the primary leveling machine 2, the transition conveyor belt 8, the secondary leveling machine 4, the conveyor belt 5 and the material receiving machine 6 are connected in sequence, and the probe module 7 and the distance measuring roller 3 are sequentially arranged on the transition conveyor belt 8 above;

[0049] Such as figure 2 As shown, the secondary leveling and shearing machine 4 includes a leveling roller 401, a control box 402, a drive motor 403, a lower knife 404, a slider 405, an upper knife 406 and a vertical distance measuring device 407, the described The bottom of the slide block 405 facing the entrance of the shearing machine is arc-shaped....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com