Simple double-piece nail box machine

A simple, box-stitching machine technology, applied in the direction of container manufacturing machinery, paper/cardboard containers, box production operations, etc., can solve the problems of corrugated cardboard folding, importing manually, low production efficiency, high labor intensity, etc., to achieve saving The effect of human resource input cost, simple structure and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

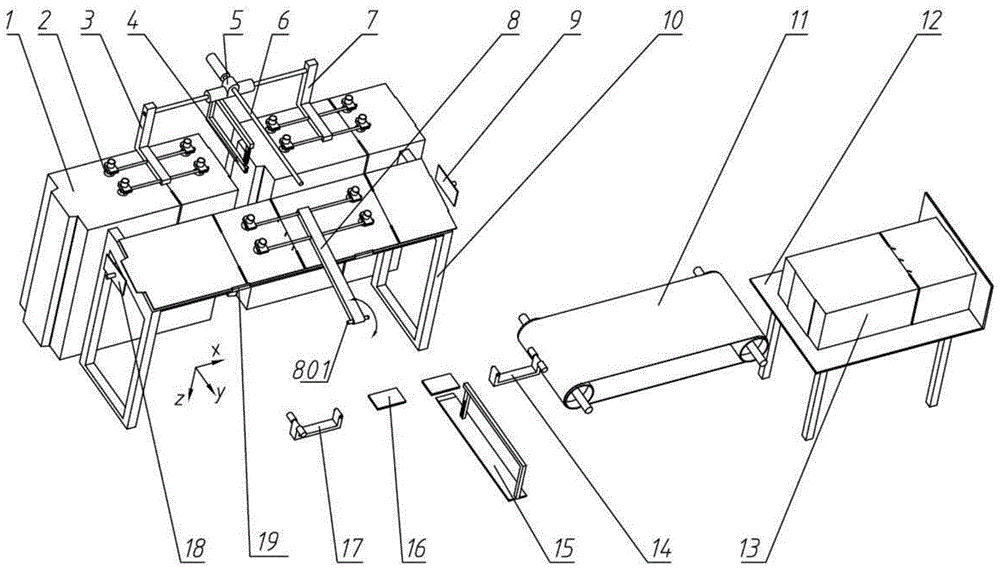

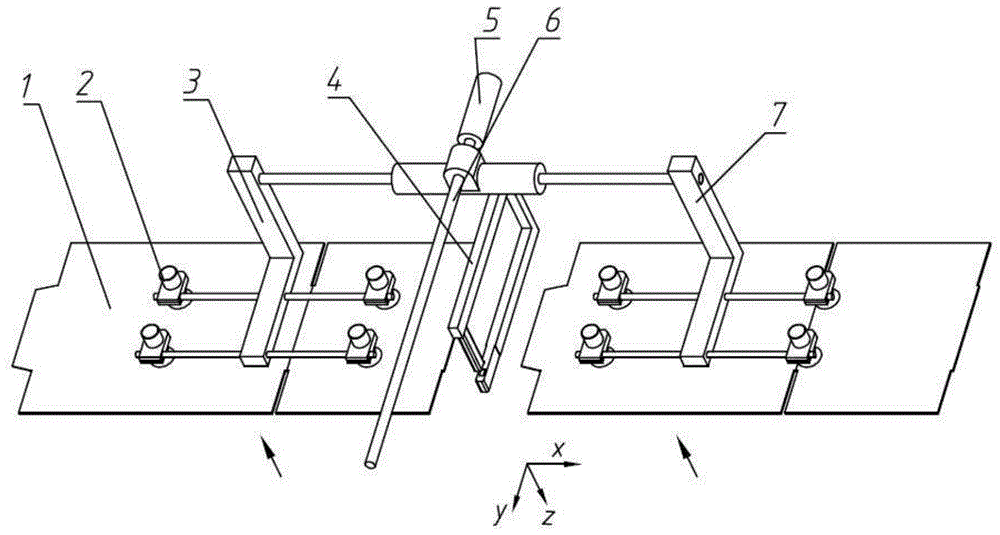

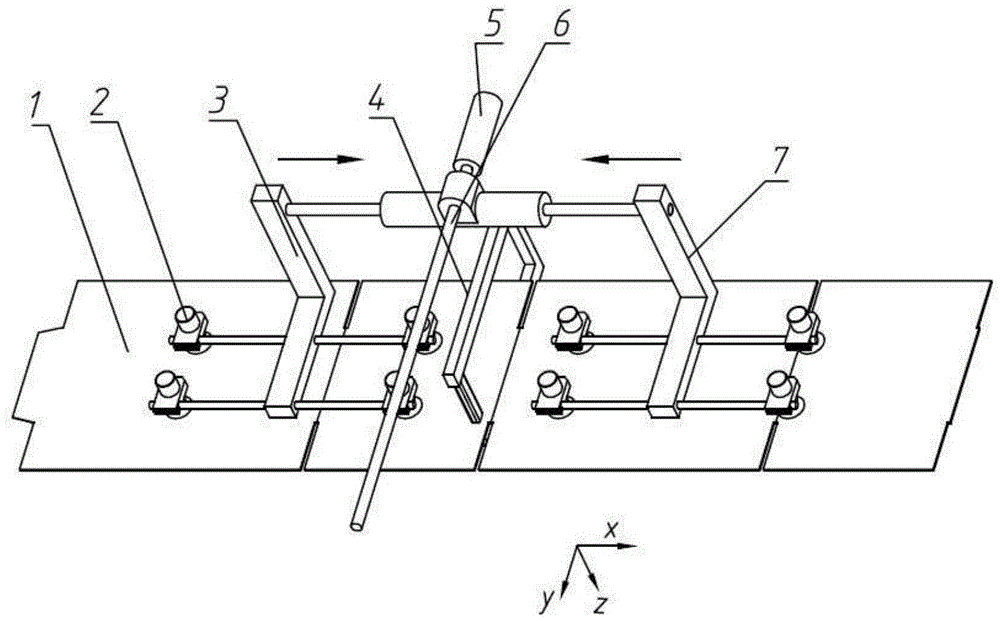

[0025] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0026] Such as figure 1 As shown, the simple double-piece nail box machine includes a mobile assembly 5 that can slide on the paper feeding guide rod 6, and a fixed nailing head 4 is provided below the paper feeding guide rod 6, and the paper stack 1 is fixed for nailing. The head 4 is arranged symmetrically to the center. With the paper feeding guide rod 6 as the center, the left suction nozzle support 3 and the right suction nozzle support 7 are respectively connected to the two ends of the moving assembly 5, and are respectively arranged on the left suction nozzle support 3 and the right suction nozzle support 7. There are a plurality of suction nozzles 2 for absorbing corrugated cardboard. In this embodiment, there are two groups of suction nozzles 2, and each group has 4 suction nozzles. Each suction nozzle 2 is arranged on the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com