Method for preventing stones from entering water turbine in rockburst areas with high buried depth, high ground temperature and high ground stress

A technology with high in-situ stress and high geo-temperature, applied in high burial depth and high geo-stress rockburst areas to prevent stones from entering the turbine in the tunnel, and in areas with high geo-temperature, it can solve problems such as reducing power generation efficiency, shutting down the water diversion power generation system, and stones entering the turbine, etc. , to improve safety and economic benefits, ensure safe operation, and avoid downtime for maintenance work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

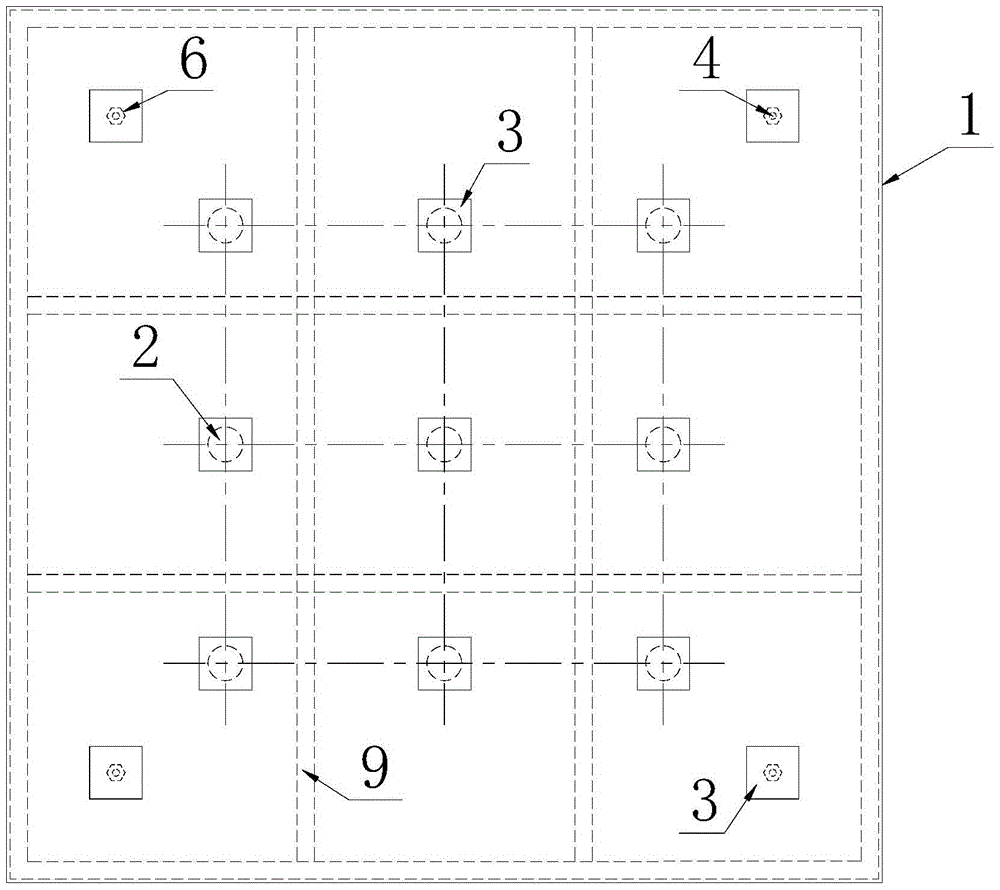

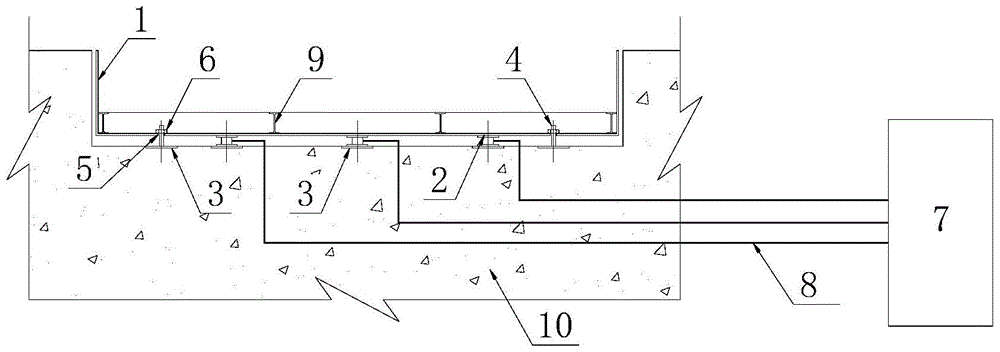

[0014] A method for preventing stones in tunnels from entering water turbines in areas with high buried depth, high ground temperature, and high ground stress rockbursts. By arranging monitoring instruments in the rock-collecting pits of power diversion tunnels, the location of the rock-collecting pits can be judged by monitoring the readings of the monitoring instruments arranged. The degree of filling determines whether to carry out block removal work.

[0015] Specifically, the following steps are included:

[0016] (1) Calibration of monitoring instruments: The monitoring instruments include an anti-corrosion metal box without a cover, a number of earth pressure gauges fixed at the bottom of the metal box, and an external reading instrument connected to the earth pressure gauge through a data transmission cable. Calibration When rocks of di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com