Upward exhaust type welded turbine condensing exhaust hood

A technology for exhausting cylinders and steam turbines, which is applied in the field of condensing and exhausting cylinders of upper-row welded steam turbines, which can solve problems such as reducing the installation height of steam turbines, reducing the installation height of input components, and increasing the installation height of steam turbines, so as to achieve lower center of gravity, lower installation height, and higher The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

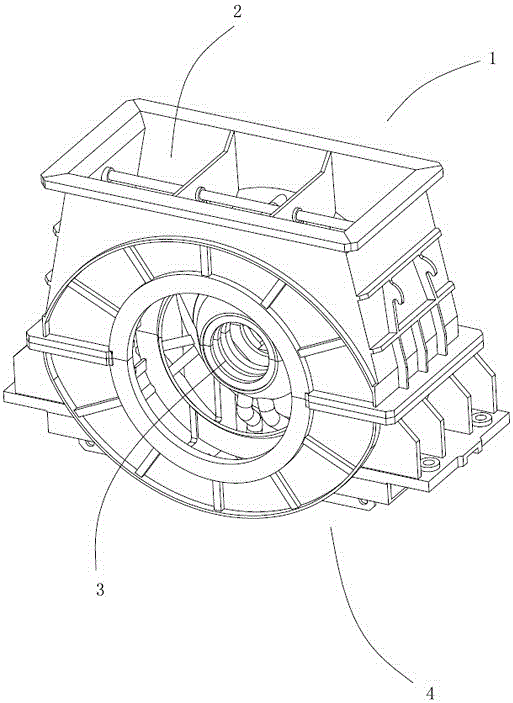

[0026] Embodiment: a kind of upper row welded steam turbine condensate exhaust cylinder (see figure 1 ), including the upper part 1 of the exhaust cylinder and the lower part 4 of the exhaust cylinder, the joint part of the upper part of the exhaust cylinder and the lower part of the exhaust cylinder is provided with a blade shaft connection part 3, and the upper part of the exhaust cylinder is provided with an upwardly facing upper exhaust port 2.

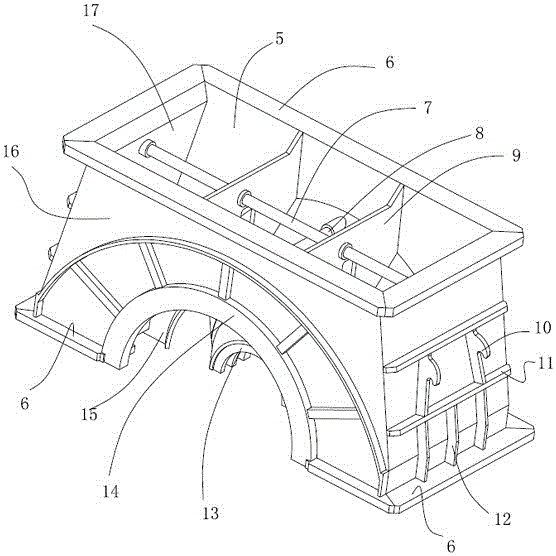

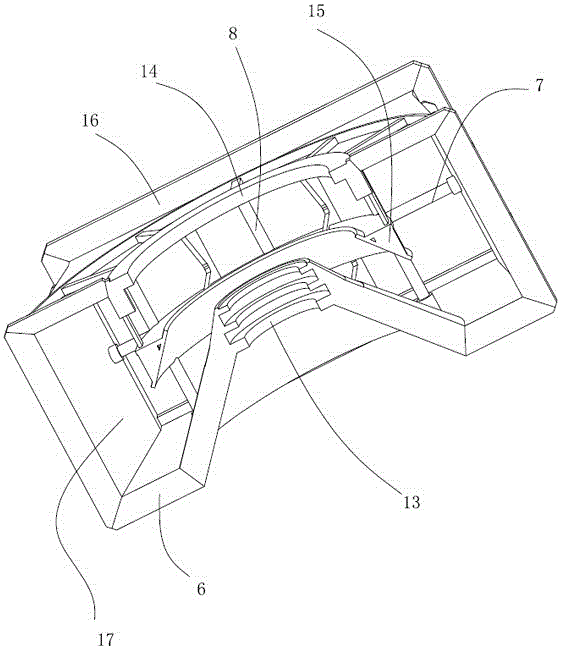

[0027] Exhaust cylinder top (see figure 2 image 3 ) is welded and fixed by two upper side walls 17, an upper front wall 16 and an upper rear wall 5; The upper exhaust port is formed, and the flange at the lower end is provided with a connection hole, and the flange at the lower end is connected with the lower part of the exhaust cylinder by bolts. An upper seal file 13 is fixed in the exhaust cylinder top, and the upper seal file is the upper half of the seal file of the whole steam turbine exhaust cylinder. The lower part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com