Horizontal type tubular pump device adopting voltage buildup gap installation

A technology of through-flow pumps and gaps, which is applied in the field of horizontal through-flow pump devices, can solve the problems of complex installation and adjustment, difficulty, and labor intensity, and achieve saving of civil engineering investment costs, good repeatability of equipment installation, and wide pump pit The effect of shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

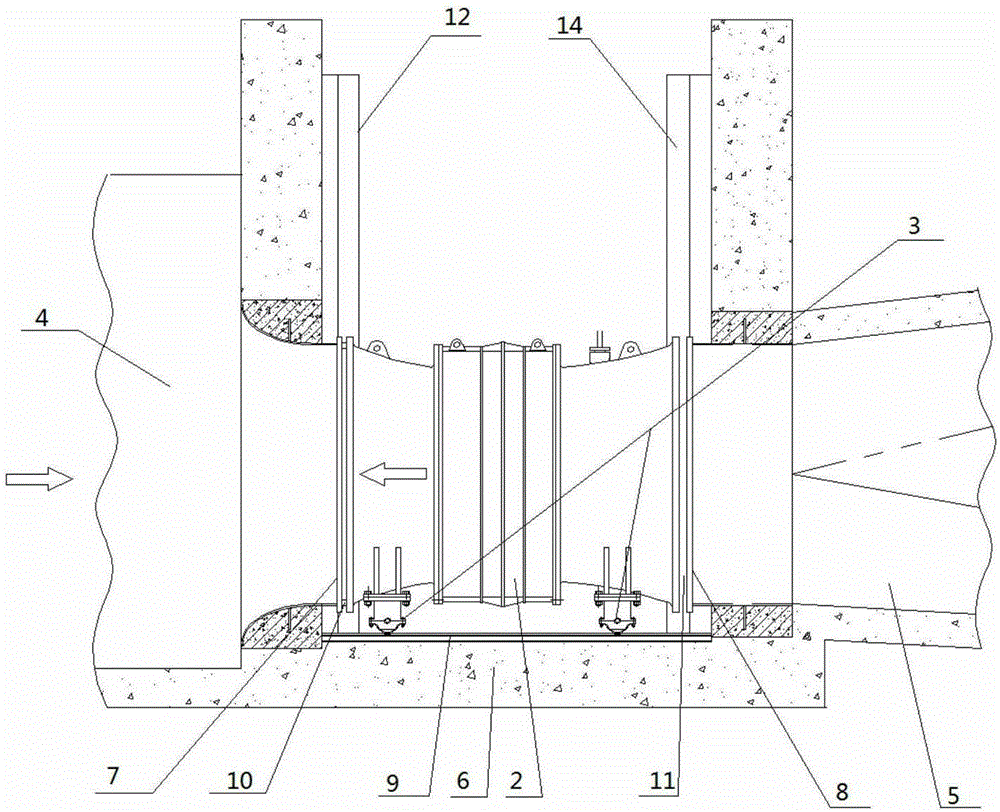

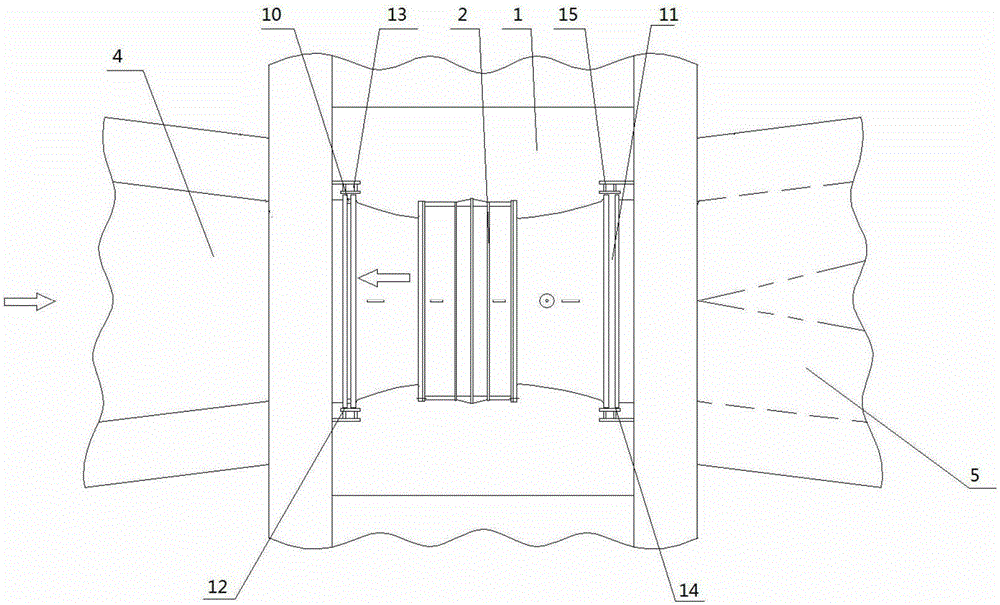

[0015] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

[0016] As shown in the figure, a horizontal tubular pump device installed with a pressure building gap includes a pump pit 1 and a tubular pump 2. Several wheelsets 3 are provided on both sides of the bottom of the tubular pump. One side of the pump pit is provided with a water inlet pool 4, and the other side is provided with an outlet pool 5; the bottom of the pump pit is provided with a base 6, and a pre-embedded water inlet pipe 7 is arranged between the water inlet pool 4 and the pump pit 1, so that A pre-buried water pipe 8 is provided between the outlet pool 5 and the pump pit 1, and a rail 9 for supporting the wheel pair 3 is provided on the top surface of the base 6; the rail 9 approaches the outlet pool from the side near the inlet pool 4 5 extends on one side; the water inlet end of the tubular pump 2 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com