Temperature control valve element

A technology of temperature control valve and valve stem, which is applied in the field of faucet spool, can solve the problems of large volume, complex structure of thermostatic faucet, high manufacturing cost, etc., and achieve the goal of avoiding excessive volume, avoiding too complicated internal structure and reducing production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

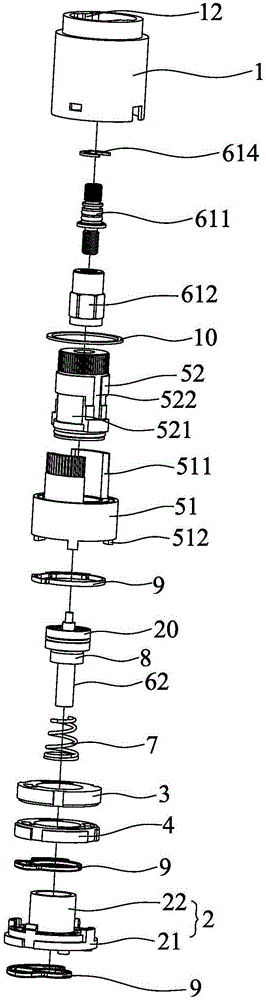

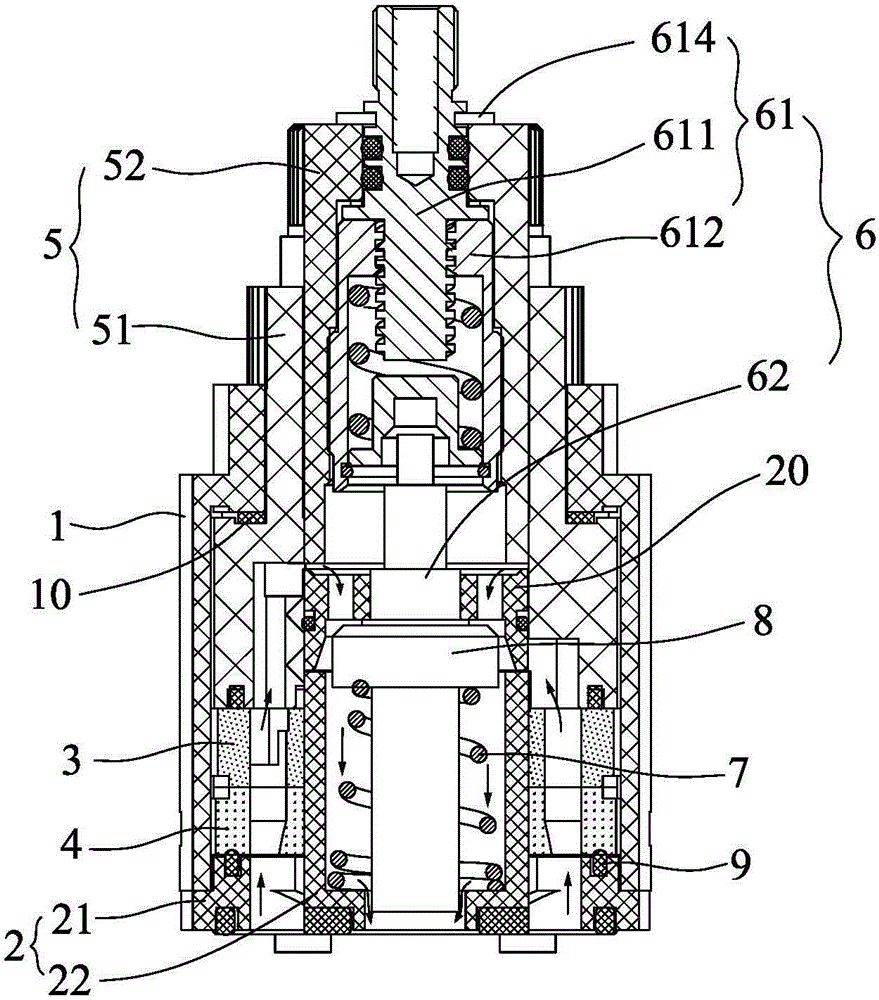

[0035] Such as Figure 1 to Figure 9 As shown, the temperature control valve core disclosed by the present invention includes:

[0036] A housing 1, forming an accommodating space 11 in the housing 1;

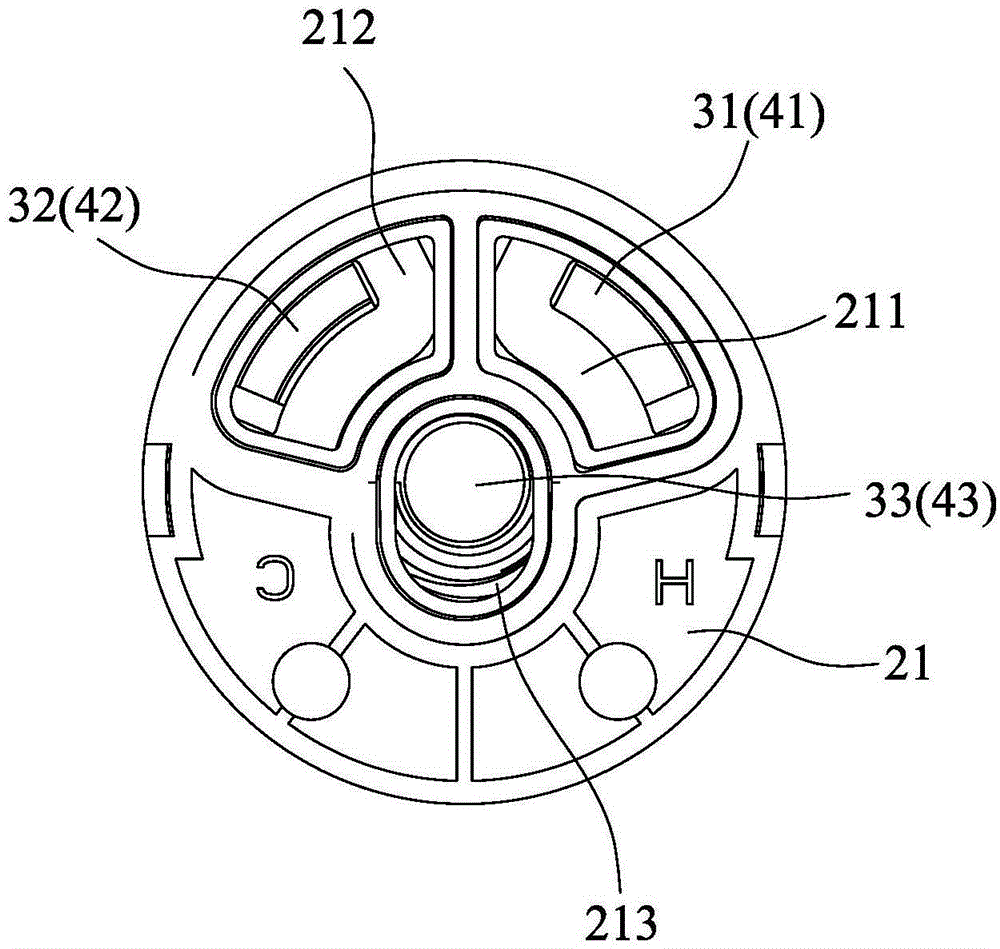

[0037] Base 2, the base 2 is socketed on the bottom of the housing 1, and the base 2 is provided with a hot water inlet, a cold water inlet and a mixed water outlet; specifically, the base 2 includes a seat body 21, and the seat body 21 and the bottom end of the housing 1 For docking, the seat body 21 is provided with a hot water inlet 211 , a cold water inlet 212 and a mixed water outlet 213 , and a spacer 22 extends upward from the periphery of the seat body mixed water outlet 213 .

[0038] The moving ceramic sheet 3 and the static ceramic sheet 4 are all socketed in the accommodation space of the housing 1, the moving ceramic sheet 3 is docked with the base 2, and the moving ceramic sheet 3 and the static ceramic sheet 4 tight fit; the moving ceramic sheet 3 and the static ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com