Trans-scale geometrical parameter measurement method based on microscopic visual sense

A microscopic vision and measurement method technology, applied in the direction of measuring devices, measuring/indicating equipment, instruments, etc., can solve the problems of large feature size span and difficult measurement of graphic parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

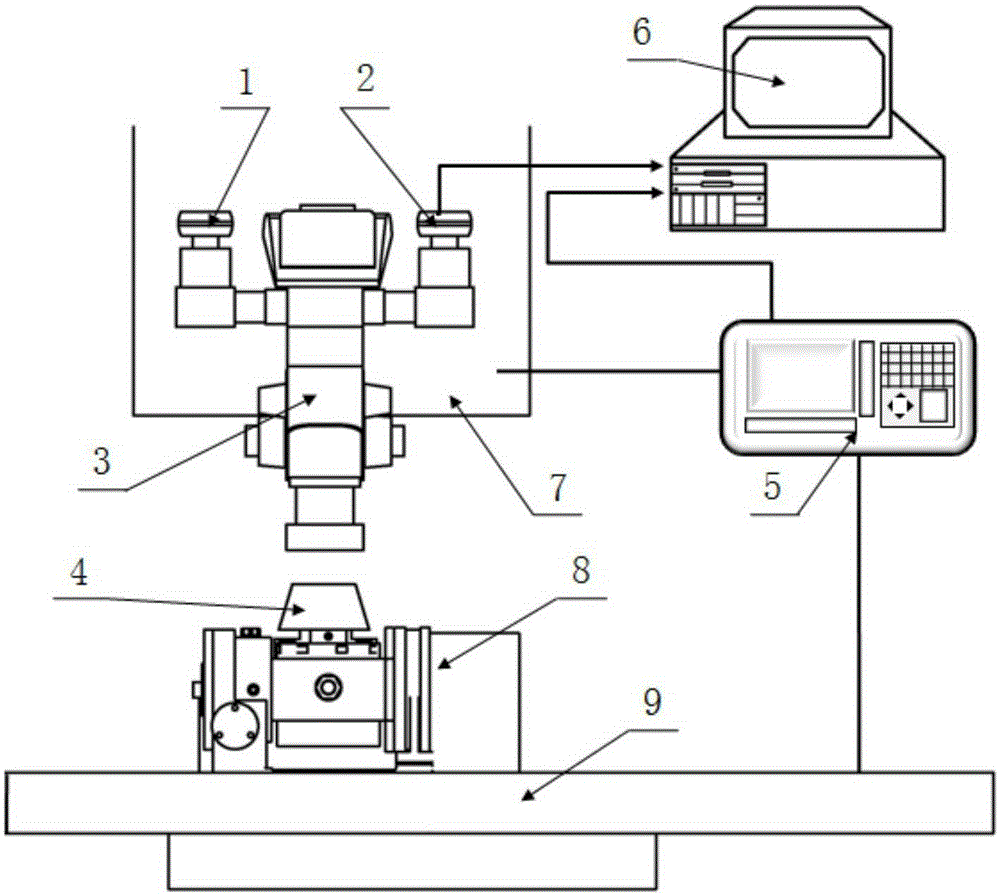

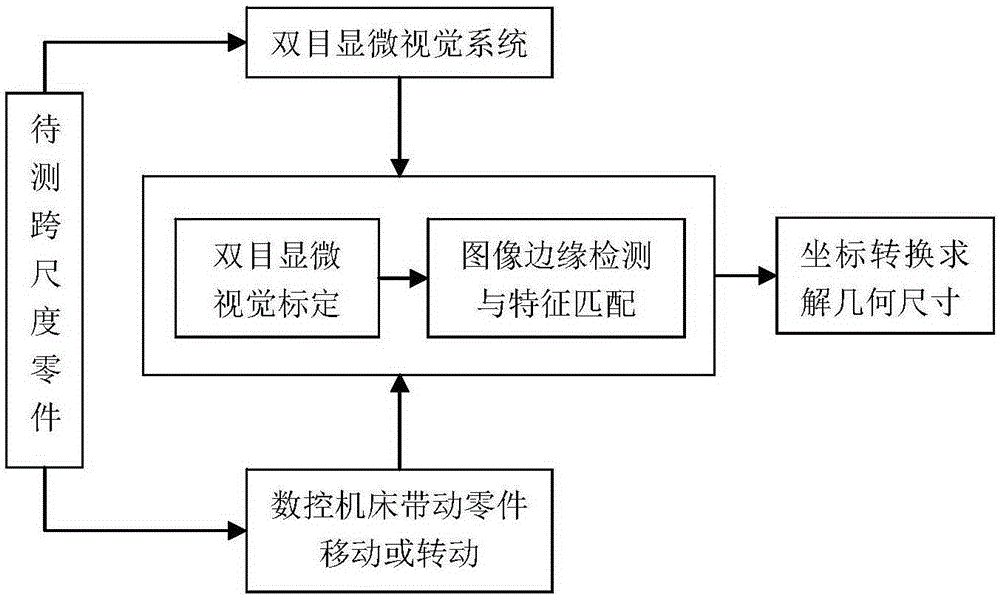

[0043] attached figure 1 It is a schematic diagram of the cross-scale measurement method based on microscopic vision. This method uses microscopic vision to measure local microscopic feature information, and drives the microscopic vision to move through the machine tool to realize the measurement of large-scale feature information, and finally solves it through coordinate transformation to fuse the two measurement results to achieve cross-scale measurement.

[0044] The high-precision moving device adopted in the present invention is a five-axis numerical control machine tool, as attached figure 1 shown. The workpiece 4 to be measured is installed on the turntable 8, and the multi-directional and multi-angle rapid measurement of the workpiece can be realized through the linear movement or rotation of the machine t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com