Method for measuring gas fraction of two-phase flow based on ultrasonic dual-frequency signal

A dual-frequency signal and ultrasonic technology, which is applied in the direction of analyzing fluids using sound waves/ultrasonic waves/infrasonic waves, can solve problems such as complex detection principles, large data processing capacity, and obstacles to two-phase fluid contact detection methods, and achieve simple detection principles and wear-through Strong penetration ability, realize the effect of online real-time measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

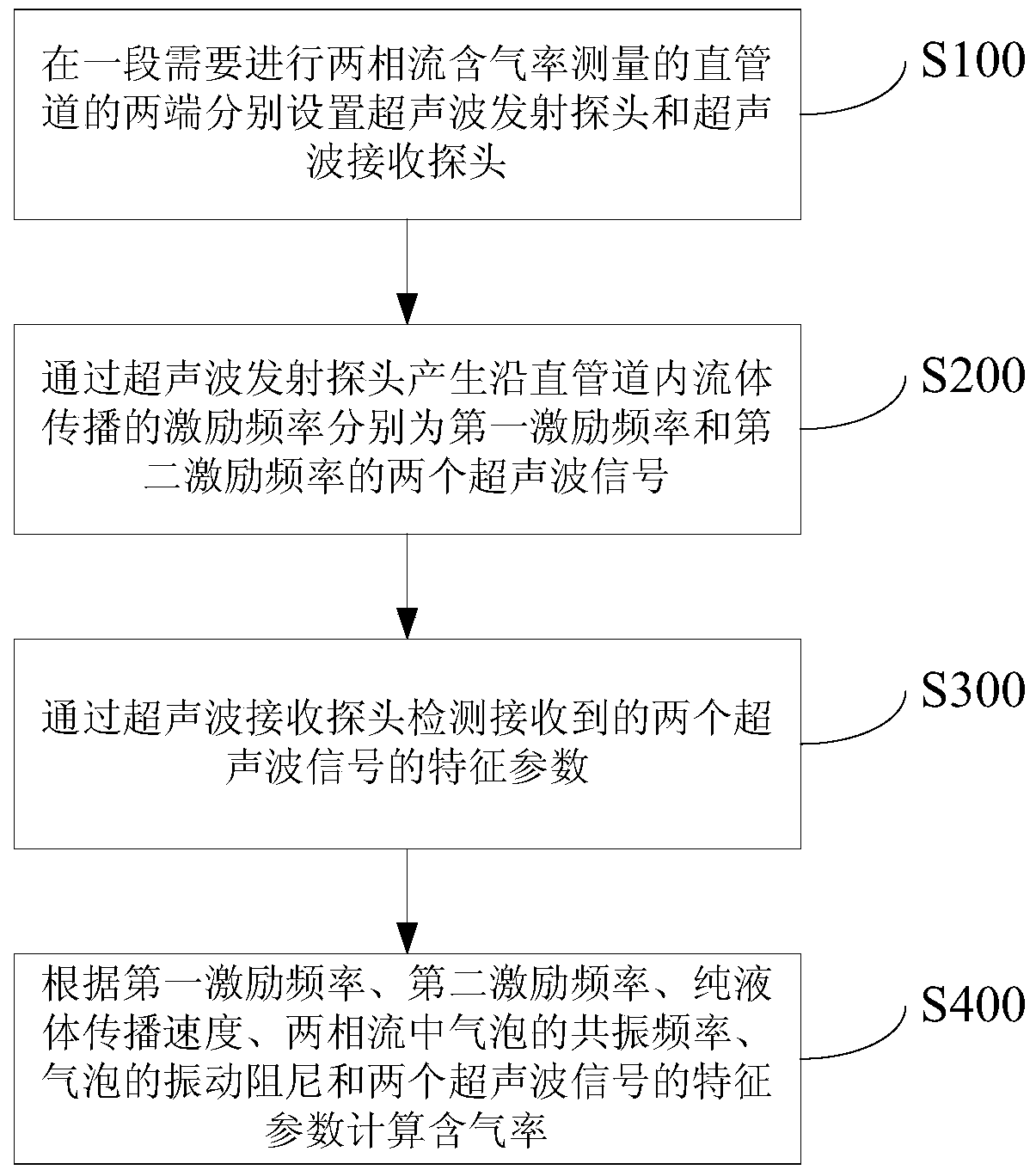

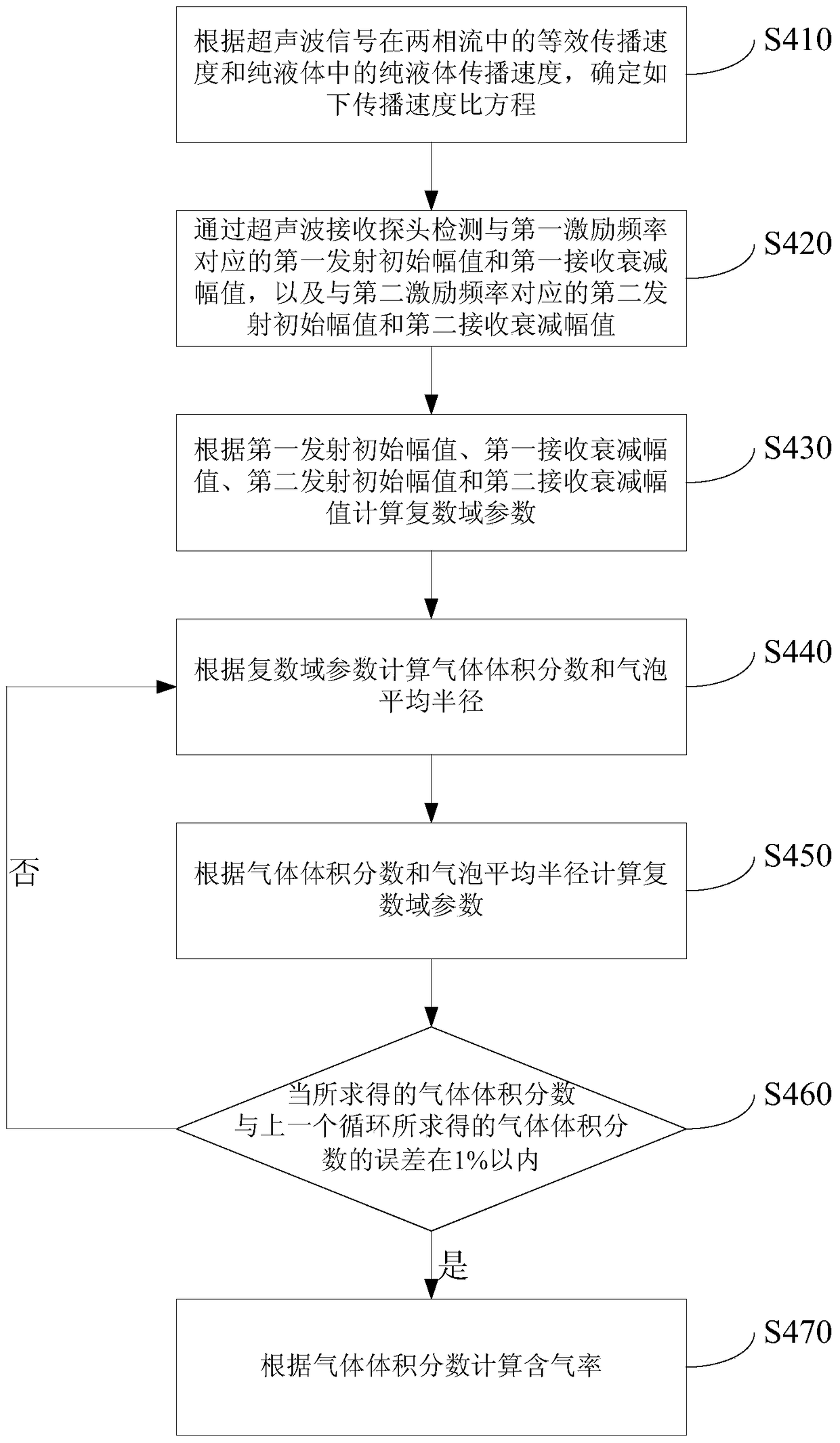

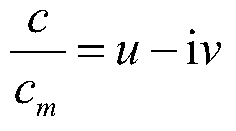

[0062] refer to figure 1 , a preferred embodiment of the present invention provides a method for measuring the gas fraction of two-phase flow based on ultrasonic dual-frequency signals, comprising the following steps:

[0063] In step S100, an ultrasonic transmitting probe and an ultrasonic receiving probe are respectively installed at both ends of a section of a straight pipeline for which two-phase flow gas fraction measurement is required;

[0064] Step S200, using the ultrasonic transmitting probe to generate two ultrasonic signals whose excitation frequencies propagate along the fluid in the straight pipeline are the first excitation frequency and the second excitation frequency respectively;

[0065] Step S300, detecting characteristic parame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com