Power battery system for electric automobile and electric automobile

A technology for power batteries and electric vehicles, applied in battery circuit devices, secondary battery charging/discharging, secondary batteries, etc., can solve the problem of increasing the difficulty of vehicle manufacturing, the cost of use and maintenance, the increase of electric vehicle curb weight, and the reduction of vehicle quality Using coefficients and other issues to overcome the contradiction between its own weight and driving range, balance the volume of the battery itself, and overcome the difficulty of charging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

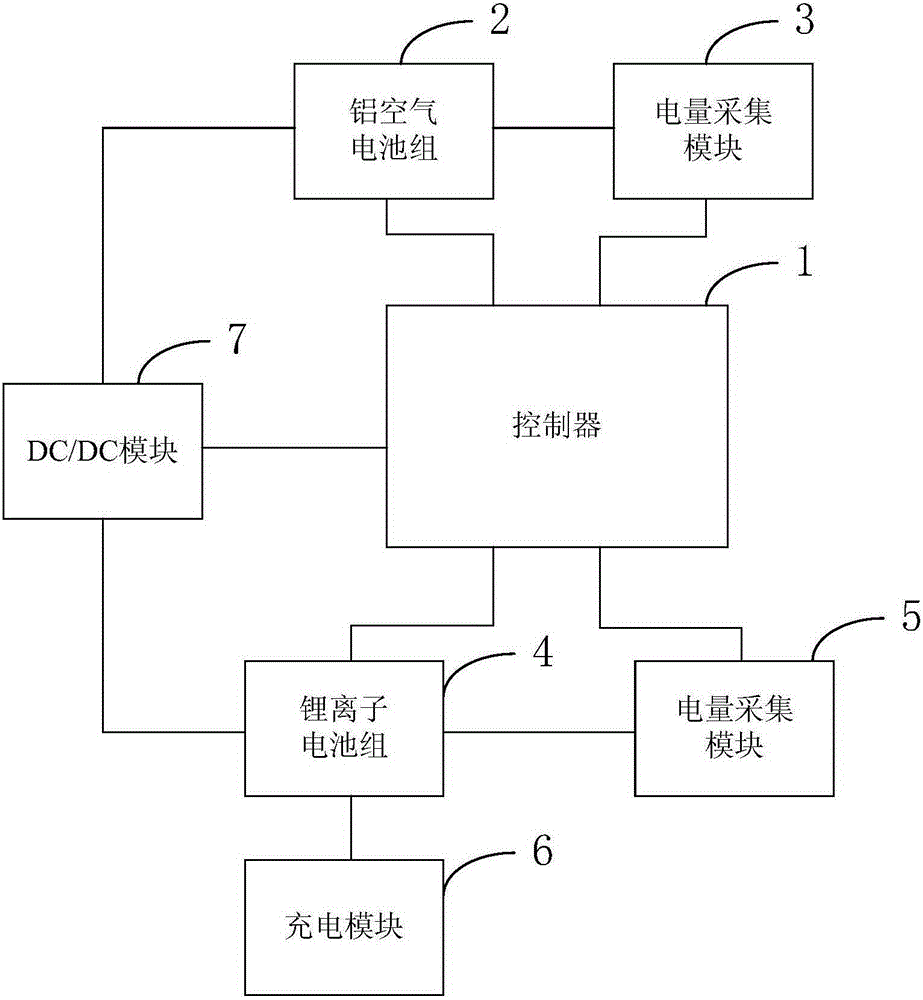

[0029] figure 1 It is a functional block diagram of a power battery system of an electric vehicle provided by an embodiment of the present invention. Such as figure 1 As shown, the power battery system includes a controller 1, an aluminum-air battery pack 2, a power collection module 3, a lithium-ion battery pack 4, a power collection module 5, a charging module 6 and a DC / DC module 7, and the output of the power collection module 3 terminal, the output terminal of the power collection module 5, the aluminum-air battery pack 2, the lithium-ion battery pack 4, and the DC / DC module 7 are all connected to the controller 1, and the input terminal of the power collection module 3 is connected to the aluminum-air battery pack 2. The input end of the acquisition module 5 is connected to the lithium-ion battery pack 4, the aluminum-air battery pack 2 is connected to the lithium-ion battery pack 4 through a DC / DC module 7, the output end of the charging module 6 is connected to the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com