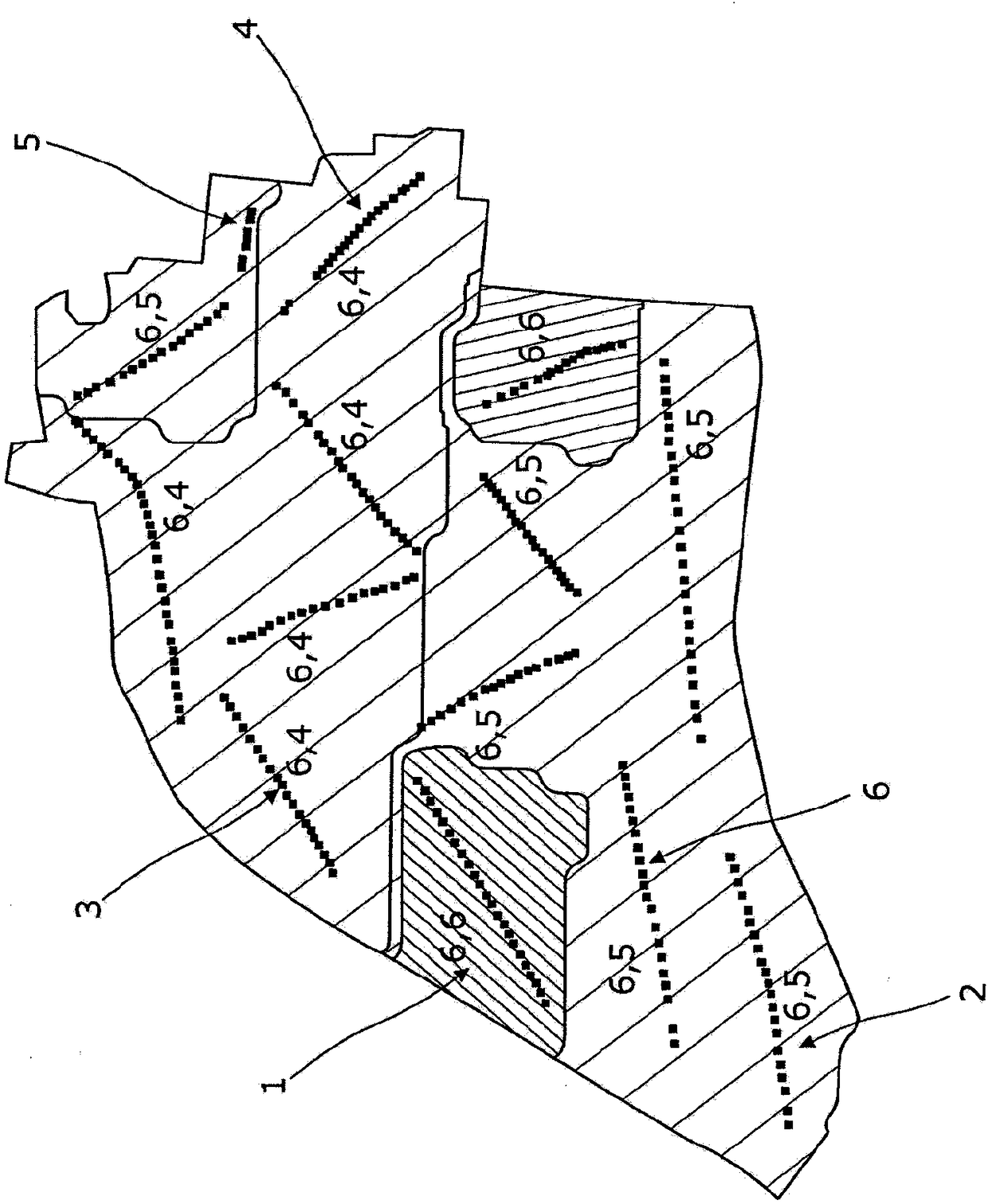

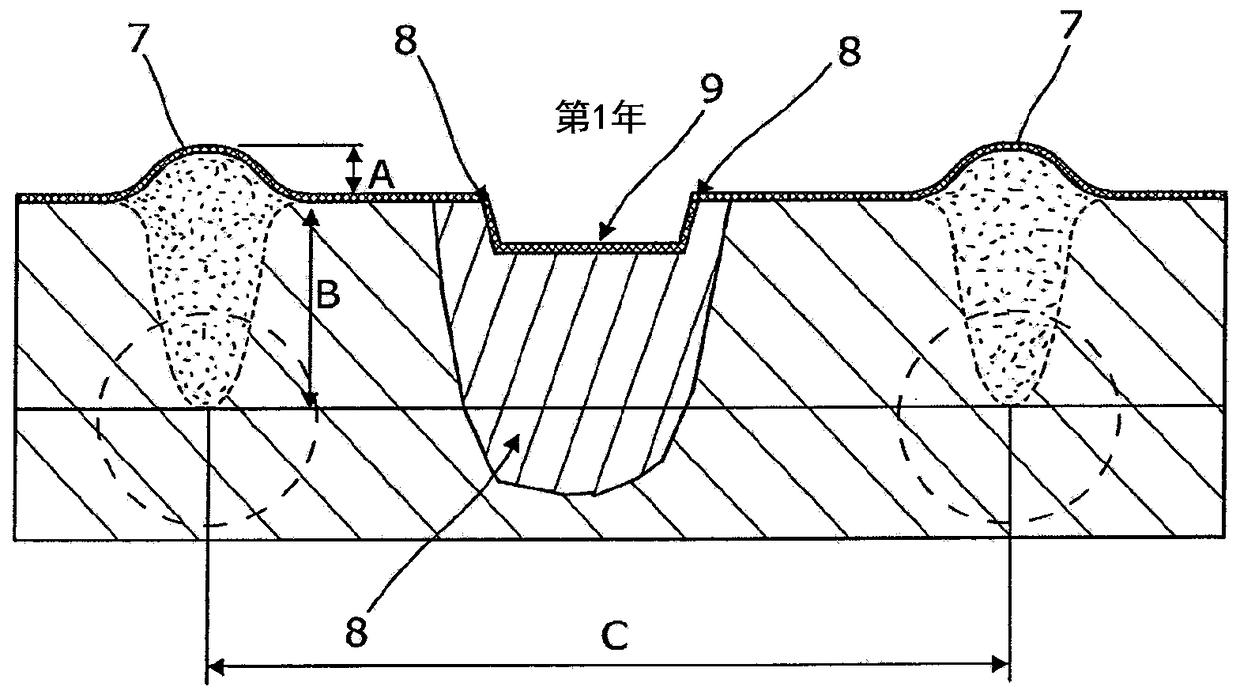

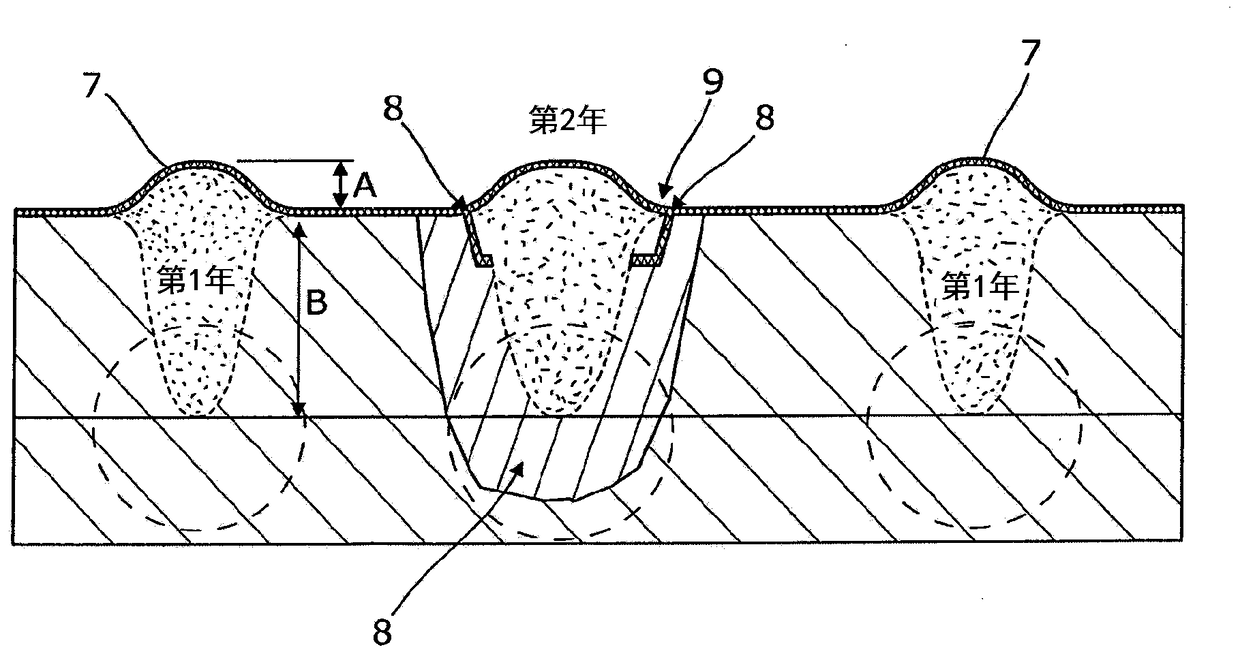

strip tillage system

A farming system and strip-shaped technology, applied in the direction of farming machines, shovels, sowing, etc., can solve the problems of good seed growth, reduced harvest, and inability to fully break the soil, so as to achieve the effect of optimizing fertilizer delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Figure 4 to Figure 8 , Figure 10 to Figure 12 A strip tillage device 11 according to the invention is shown. The apparatus 11 comprises: at least one tillage unit (commonly referred to as a "set") 13, each set 13 including an adjustable tooth 15; and a control system 17 for adjusting the position of each tooth 15 relative to its corresponding set. Group 13 position.

[0061] The arrangement of one set 13 will be described in more detail below, which description is applicable to each set 13 (of the six illustrated).

[0062] Cover set 13 comprises support frame 19 (see Figure 5 and Figure 7 ). The support frame 19 includes a first support member 19a and a second support member 19b. The first support member 19a and the second support member 19b are disposed substantially parallel to and spaced apart from each other. The tooth 15 is mounted on the support frame 19 between the first support member 19a and the second support member 19b in such a way that the contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com