Multi-buckle connection structure of front panel and side panel of drawer

A connection structure and front panel technology, which is applied in the direction of thin plate connection, connection components, drawers, etc., can solve the problems of time-consuming, unfavorable fast assembly or disassembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions claimed in the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

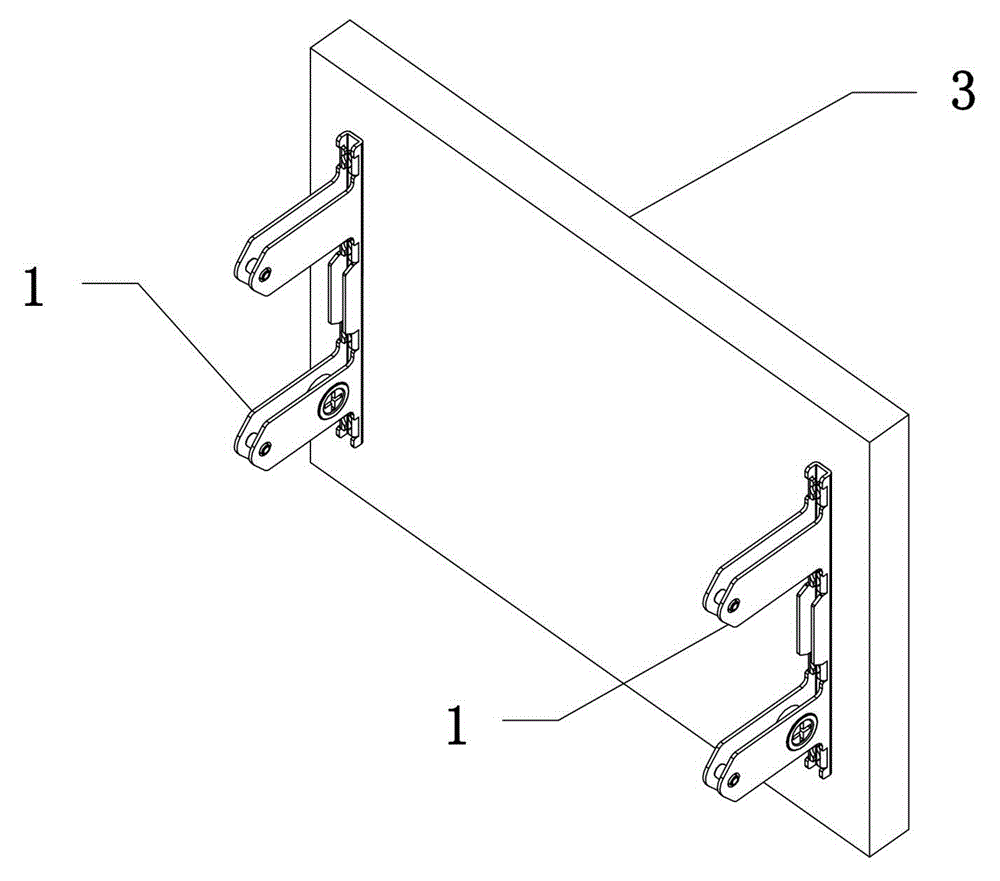

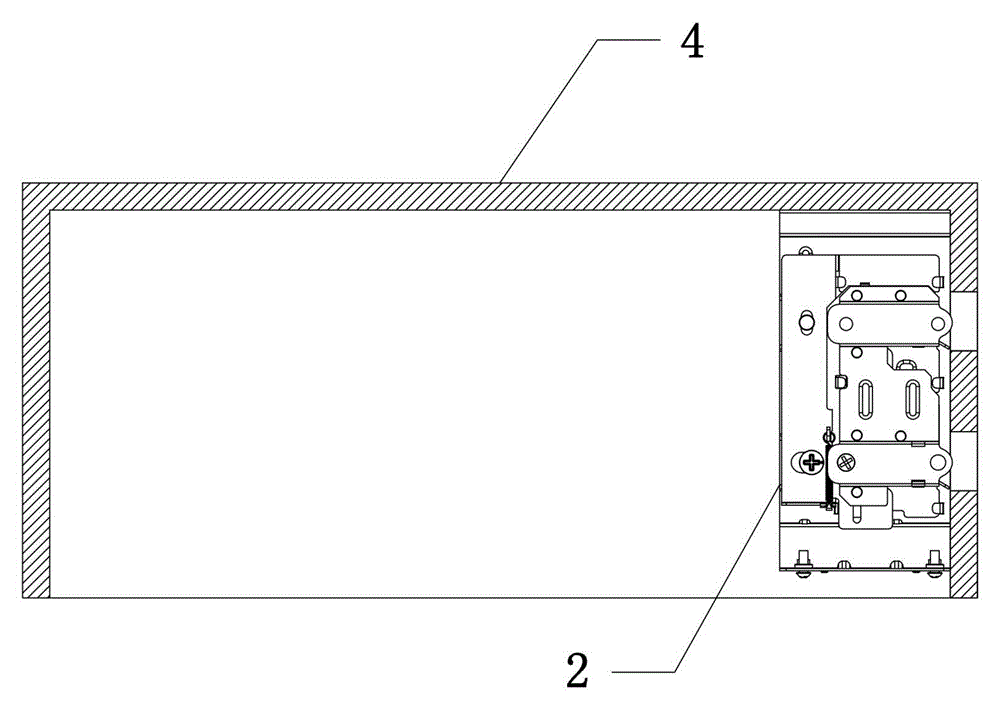

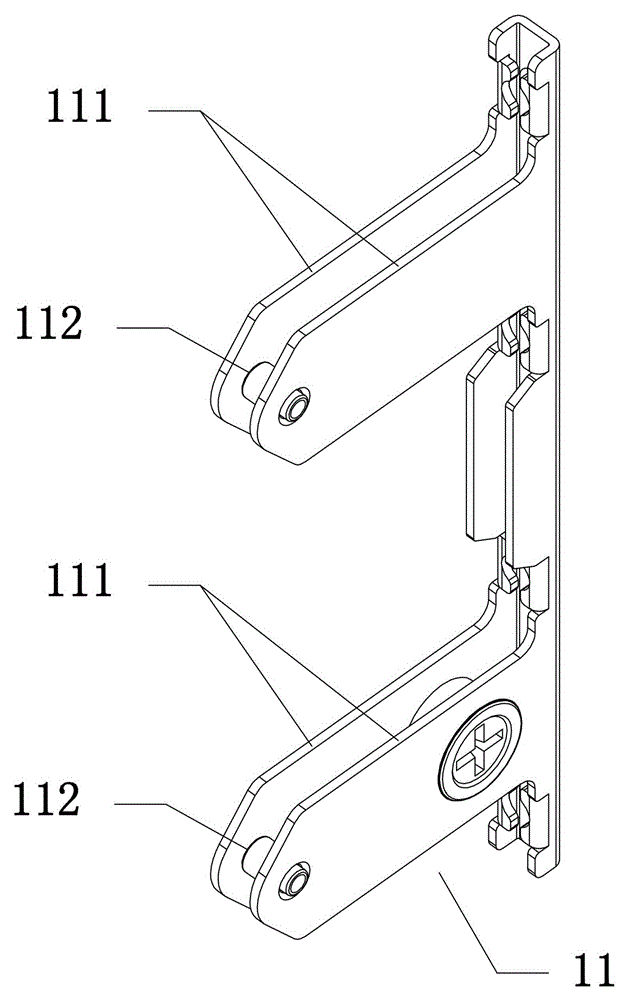

[0026] See attached figure 1 to attach Figure 7 As shown, in this embodiment, the single buckle connection structure of the drawer front panel 3 and the side panel 4 includes a buckle 1 and a panel connection assembly 2 . Wherein the buckle 1 includes two plugs 11 composed of two mutually parallel plugs 111, and each plug 11 is arranged on the same straight line. In other embodiments, the number of plugs 11 can be N, and N is greater than or equal to two. , There is a gap between the two inserts 111 on the same plug 11 , and a circular shaft-shaped block 112 axially perpendicular to the two inserts 111 is provided in the gap. In this embodiment, the buckle 1 is connected and installed on the front panel 3 , and its plug 11 is perpendicular to the surface of the front panel 3 . The buckle 1 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com