Adjustable supporting device of magnetic powder pressing automatic production line feeding plate

A technology of automatic production line and support device, applied in the direction of supporting machine, machine table/support, non-rotation vibration suppression, etc., can solve the problems of non-adjustment, offset of support rod, neglect of adjustment, etc., and achieve fine adjustment of the position of the feeding plate , The adjustment method is accurate, and the effect of stable adjustment is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

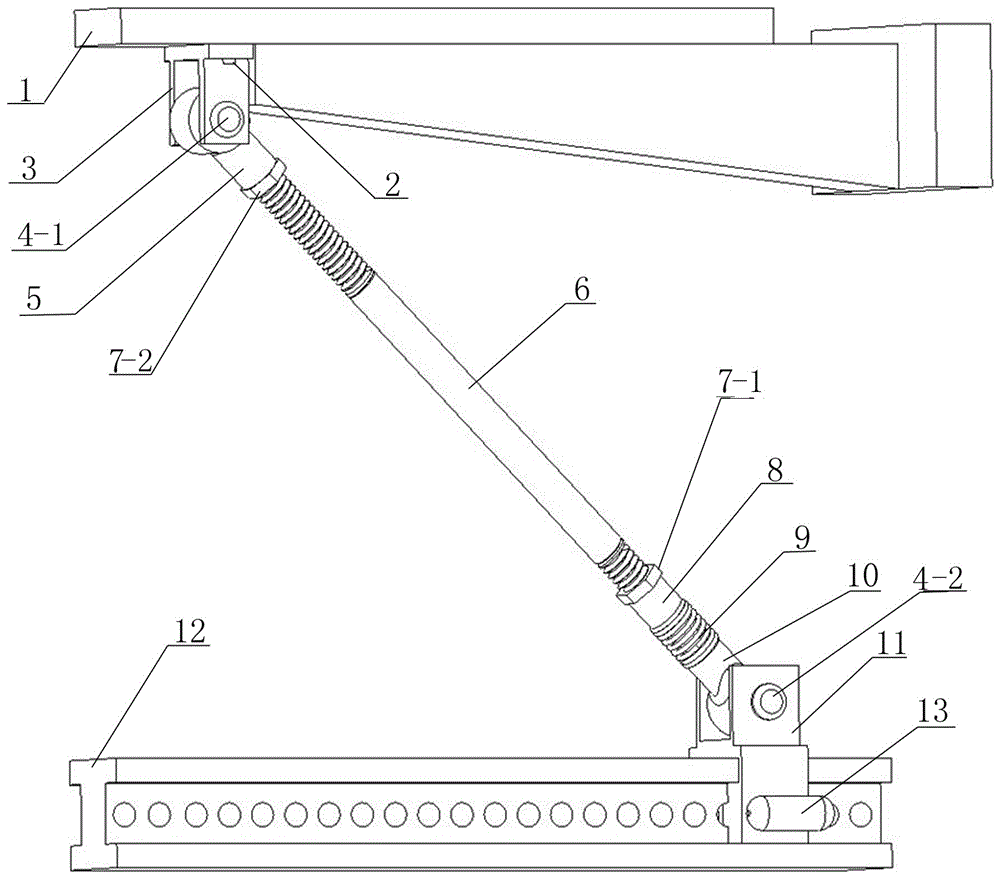

[0027] refer to Figure 1-2 , an adjustable supporting device for a feeding plate of a magnetic powder pressing automatic production line, including a feeding plate 1, an I-shaped guide rail 12, and a double-headed stud 6 arranged between the feeding plate 1 and the I-shaped guide rail 12, and also includes a reduction Vibration device, the upper end of described double-ended stud 6 is connected with feeding plate 1, and the lower end is connected with shock absorber, and shock absorber is connected with I-shaped guide rail 12.

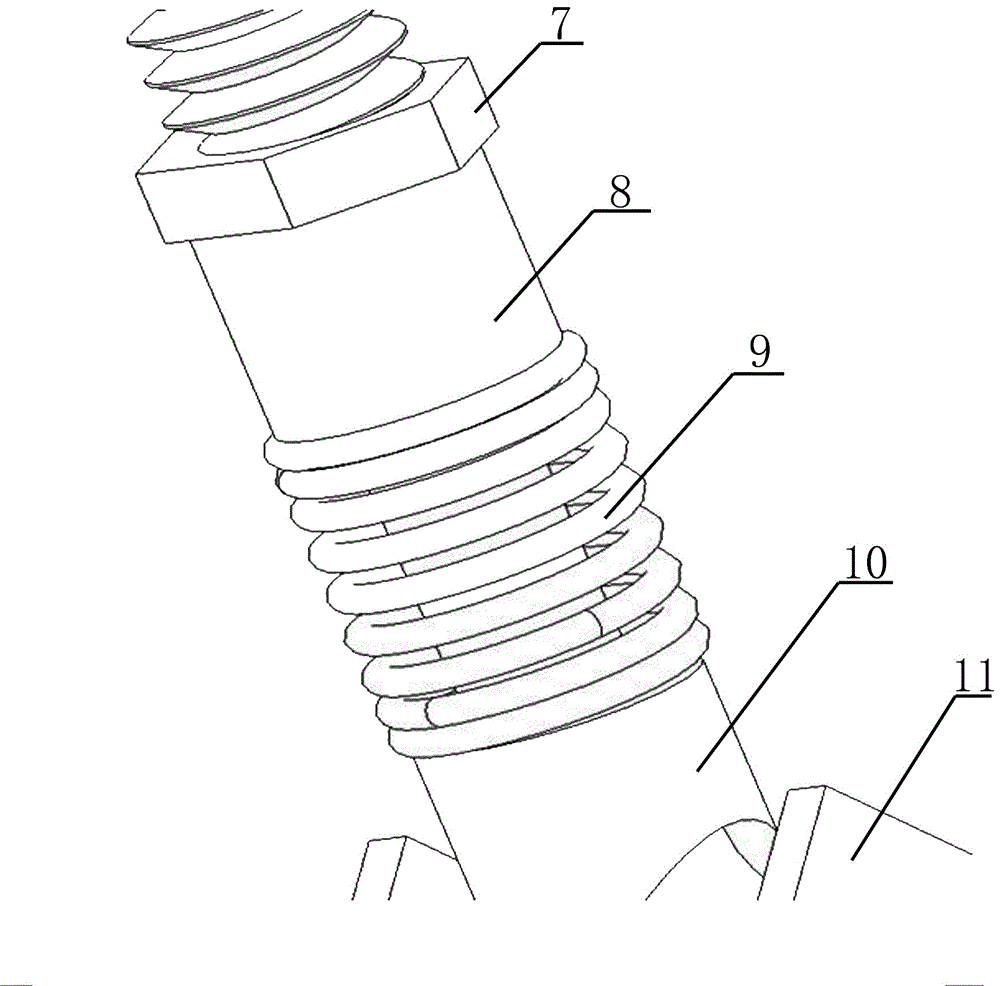

[0028] Described damping device is made up of spring 9, the first connector 10 that is located at the two ends of spring 9 and the second connector 8, and the first connector 10 is a cylindrical polished rod, and the second connector 8 is a cylindrical rod that is provided with internal thread , the lower end of the double-ended stud 6 is screwed into the upper cylindrical rod of the second connecting piece 8, and a first nut 7-1 is provided to tighte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com