Implementation method of conducting dry-wet cycle by simulating soil body bearing load in engineering

A dry-wet cycle and realization method technology, applied in the direction of soil material testing, weighing by removing certain components, material inspection products, etc., can solve the problems of affecting the experimental results, large difference, slow dry-wet cycle process, etc., to achieve The effect of simple and cheap installation, convenient engineering application and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

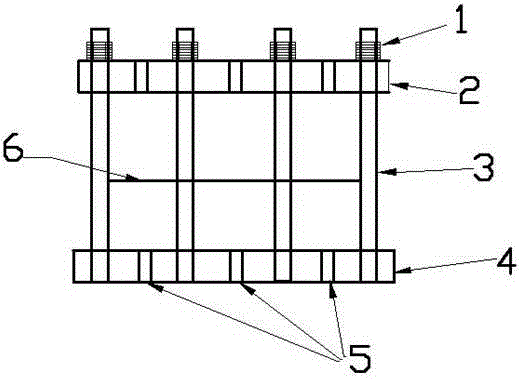

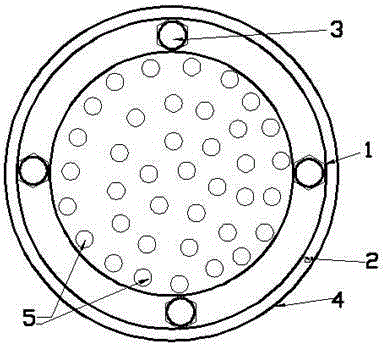

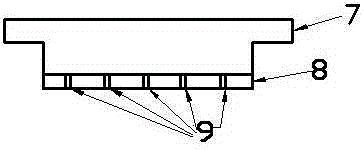

[0023] (1) Set up a device that simulates the dry-wet cycle of the soil under load in the project, including nut 1, fixed ring 2, vertical rod 3, lower bottom plate 4, lower bottom plate drainage hole 5, ring knife 6, cross Ridge 7, upper cover plate 8 and upper cover plate drainage hole 9, the full length of vertical rod 3 is threaded and is fixedly connected with lower base plate 4; cm; the internal diameter of the fixed ring 2 is slightly larger than the outer diameter of the ring knife 6, which is convenient for the ring knife 6 to be put in, and four vertical grooves are arranged at the diagonal positions on the ring wall of the fixed ring 2, and the internal thread of the vertical groove and the thread of the vertical rod 3 are interlocked, and the nut 1. The internal thread and the thread of the vertical rod 3 interlock; the whole device is made of PEEK plastic.

[0024] (2) make the ring knife sample 12 of required water content according to the experimental plan, resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com