Locking device

A technology for locking devices and locking positions, applied in transportation and packaging, web wheels, connecting components, etc., can solve problems such as time-consuming, achieve high-speed connection process, time-limited or permanent connection, and shorten the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

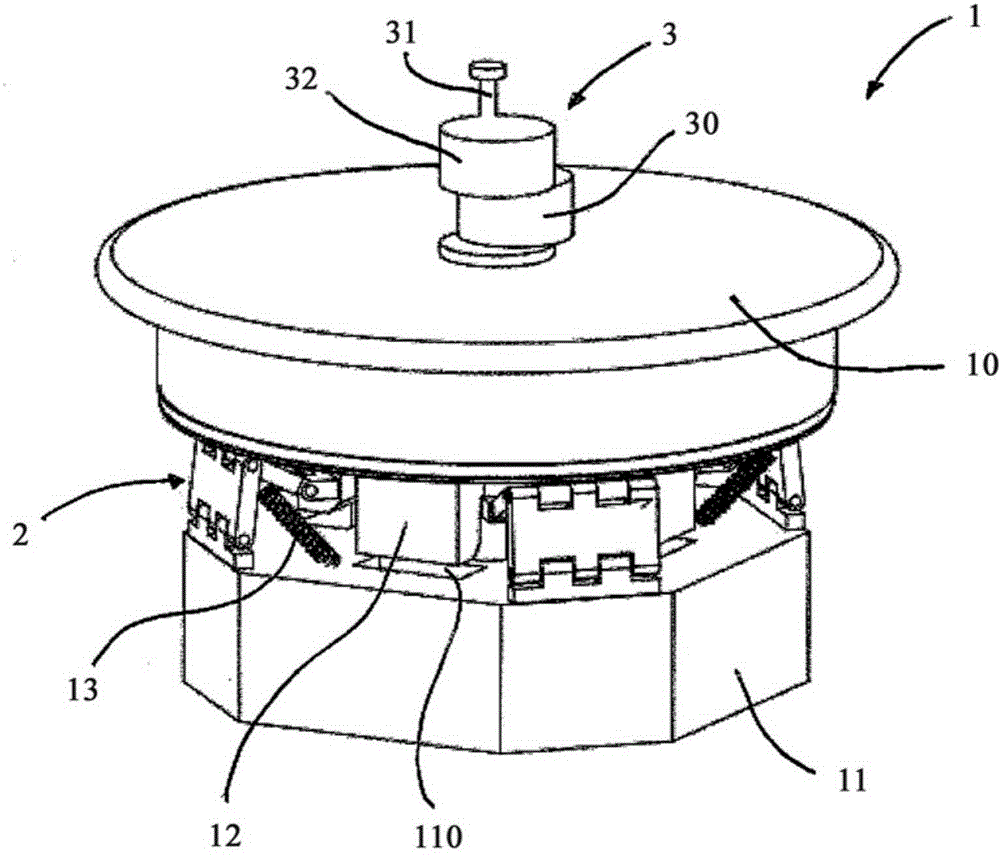

[0066] figure 1 The locking device 1 shown has an actuating mechanism 10 which, in particular, is connected directly to the fixing device 3 . The fixing device 3 has a fixing screw 31 , a cylindrical extension 32 and an eccentric cylindrical disk 30 . Here, the cylindrical extension 32 supports the fixing bolt 31 . In particular, the cylindrical extension 32 has a groove into which the fixing bolt 31 can be releasably guided. The diameter of the cylindrical disk 30 may correspond to the diameter of the cylindrical extension 32 .

[0067] On the side of the actuating mechanism 10 opposite to the fixing device 3, the actuating mechanism is via one, or such as figure 1 Mechanical displacement means in the form of four folding means 2 shown by way of example are connected to the base body 11 . The actuating mechanism 10 is movable relative to the base body 11 . The displacement device 2 is coupled to the base body 11 via a tensioning device 13 in the form of a spring. The te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com