A method and device for synchronous feeding and feeding of a whole roll of thin plate coil barrel

A technology of synchronous feeding and feeding device, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of large feeding error of feeding device, damaged proximity switch, scrapping of scratched parts, etc., and achieves simple and convenient operation. Setup, easy-to-master effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

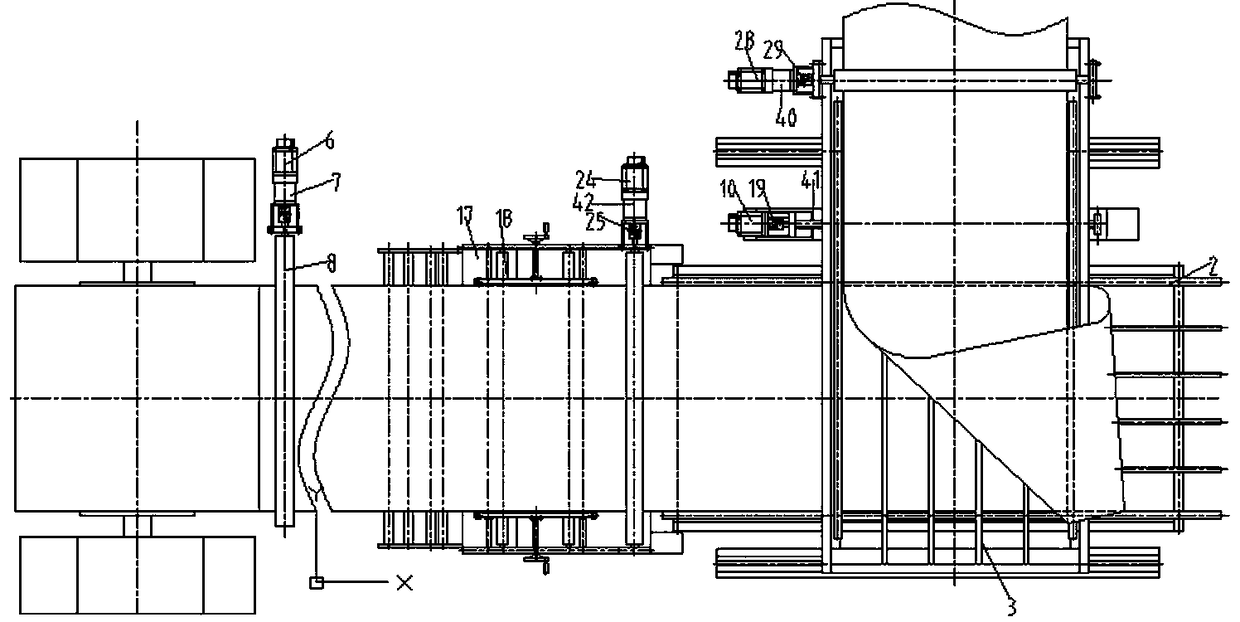

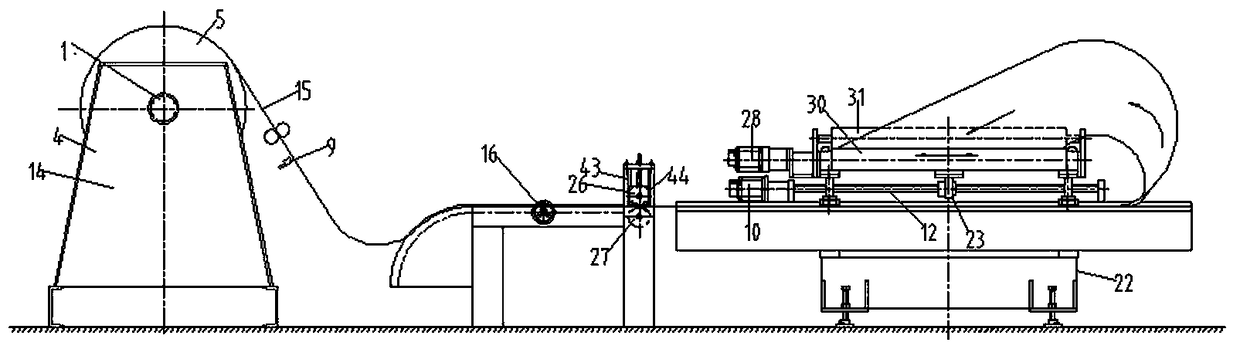

[0031] The method of synchronously feeding and feeding the whole roll of coil barrel is:

[0032] A Unwinding of roll material

[0033] Coil material 5 is contained on the main shaft 1 of uncoiler 4, and main shaft 1 is installed on the frame 14 by bearing. A pair of unwinding pull rollers clamp the blank strip. The uncoiling motor 6 drives the uncoiling traction roller to rotate through the reducer 7, so that the coil material 5 is continuously unrolled into a sheet material strip.

[0034] Guidance and turning of the B sheet belt

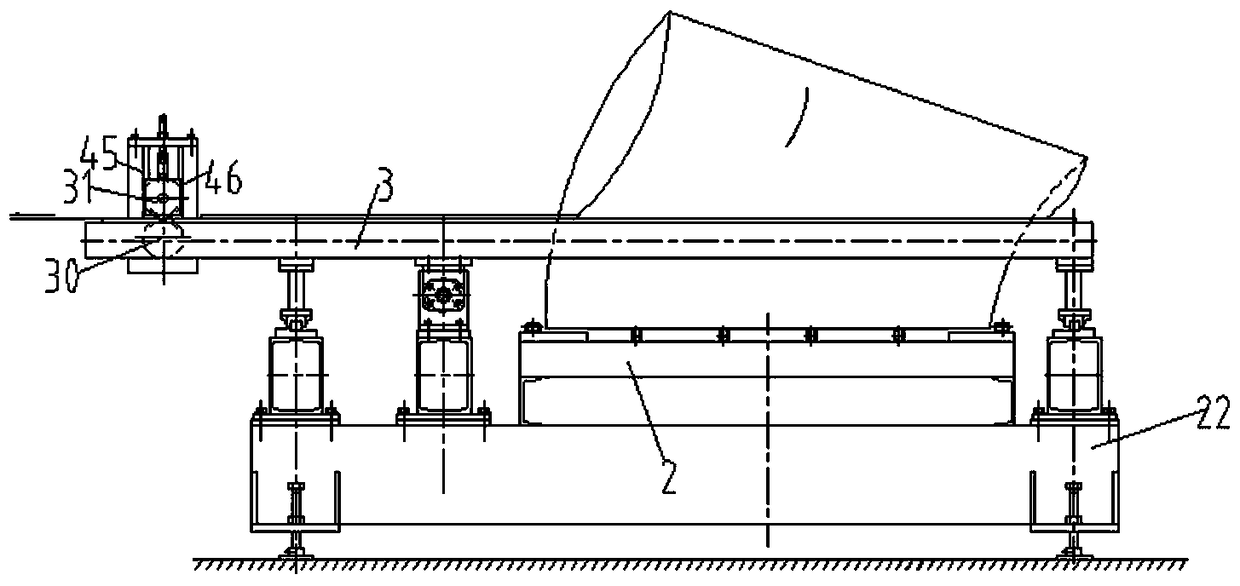

[0035] The sheet material strip that has been opened is laid flat on the lower support frame 2 through the guide device, passes through the upper support frame 3 that resides above the lower support frame 2 and crosses the lower support frame at 290 degrees, turns upward and After the space is turned 90 degrees, it is laid flat on the upper support frame 3, and the synchronization of the front and rear longitudinal feeding systems ensures that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com