A quick release cap device

A technology of mouth cover and hole cover, which is applied in the direction of aircraft accessories, etc., can solve the problems that the structural integrity and working reliability cannot be guaranteed, the accuracy of payload detection data is affected, and many operations are required for disassembly and installation, so as to achieve a simple and reliable structure , Occupy a small internal space and ensure the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and examples.

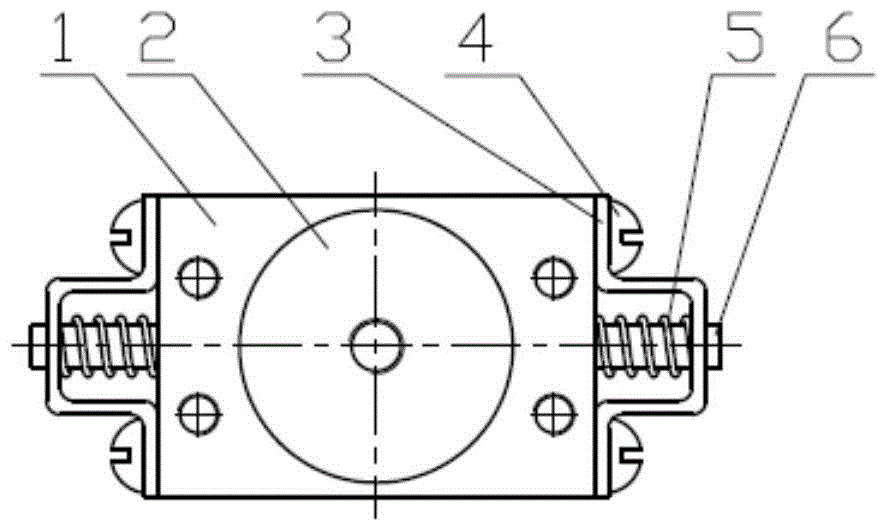

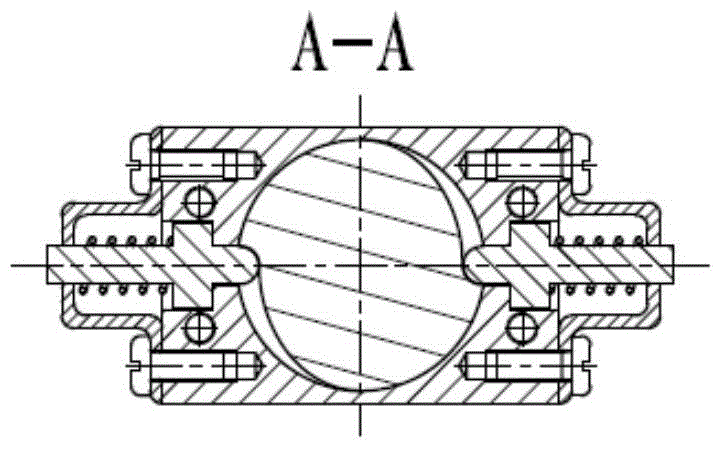

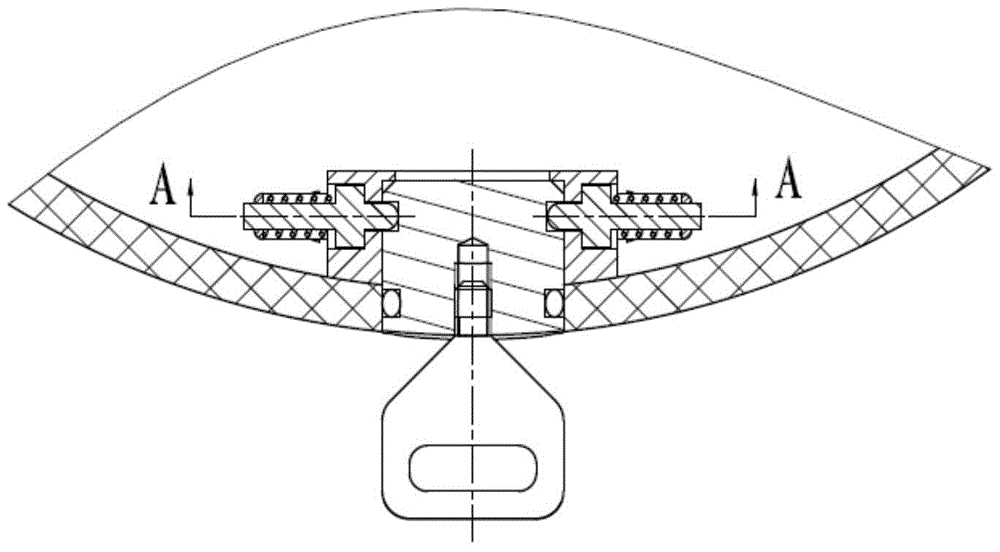

[0024] Such as figure 1 As shown, the quick-release cover device of the present invention includes: a base 1, a hole cover 2, a limit card 3, a limit pin 6, and a switch key 7;

[0025] A through hole is processed on the base 1, and the inner wall of the cabin corresponding to the through hole is hollowed out, and the through hole is matched with the hole cover 2; the cylindrical surface of the hole cover 2 is processed with two 90-degree elliptical arcs along the circumference The starting ends of the two elliptical arc grooves are smoothly transitioned to the cylindrical surface, and the two arc grooves are located on the same circumference and distributed symmetrically to the center; one end of the limit pin 6 is provided with a limit platform; the hole cover 2 is provided with a threaded hole , the threaded hole is matched with the switch key 7, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com