Plate chain belt conveyor

A technology of belt conveyor and plate chain, which is applied in the field of automobile dismantling and conveying equipment, can solve the problems of unfavorable influence on the normal and stable operation of the scrapped automobile dismantling production line, easy to get stuck in small iron filings, etc., and achieve simple and reliable structural settings, and update The cost of replacement is reduced and the effect of avoiding material jams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

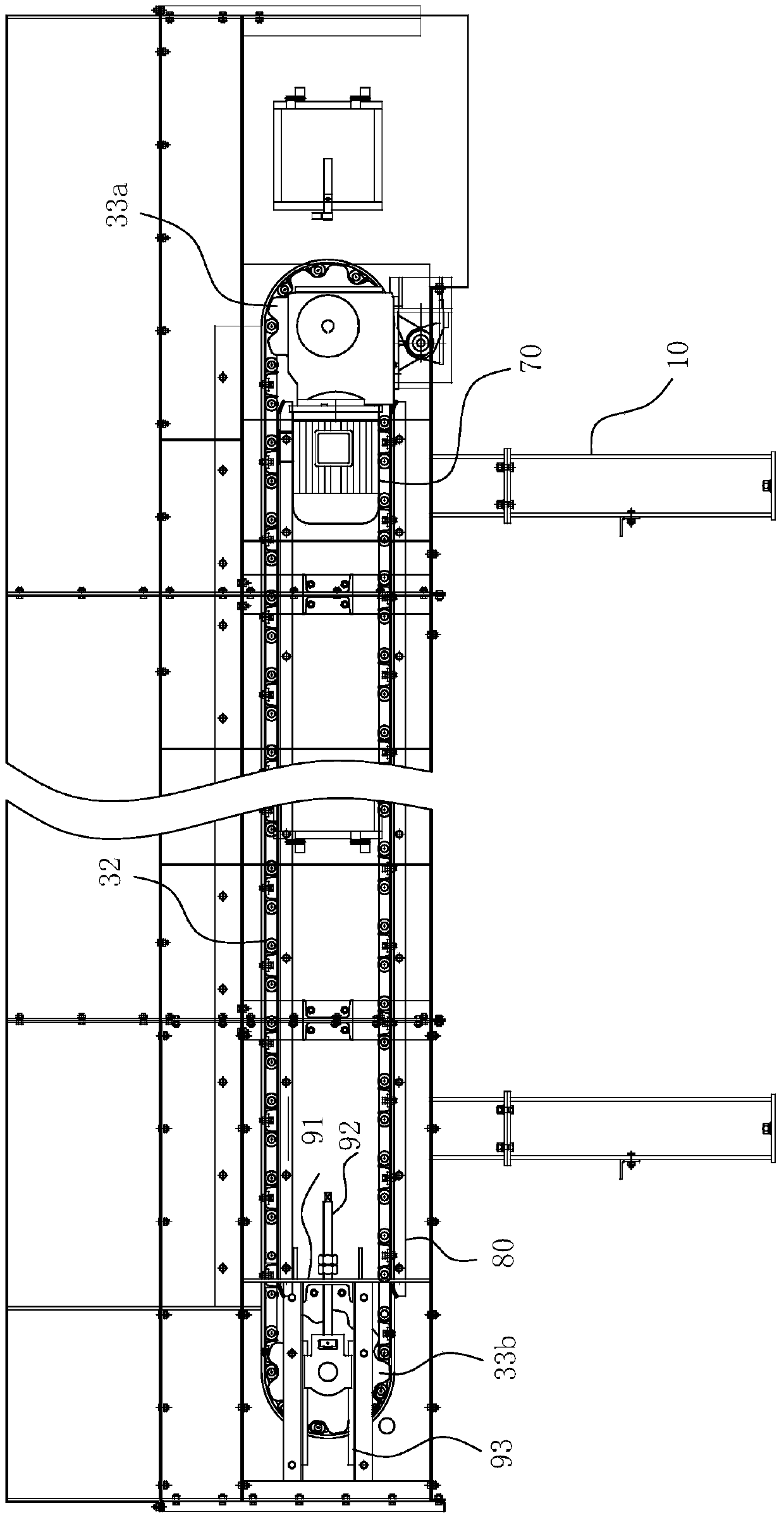

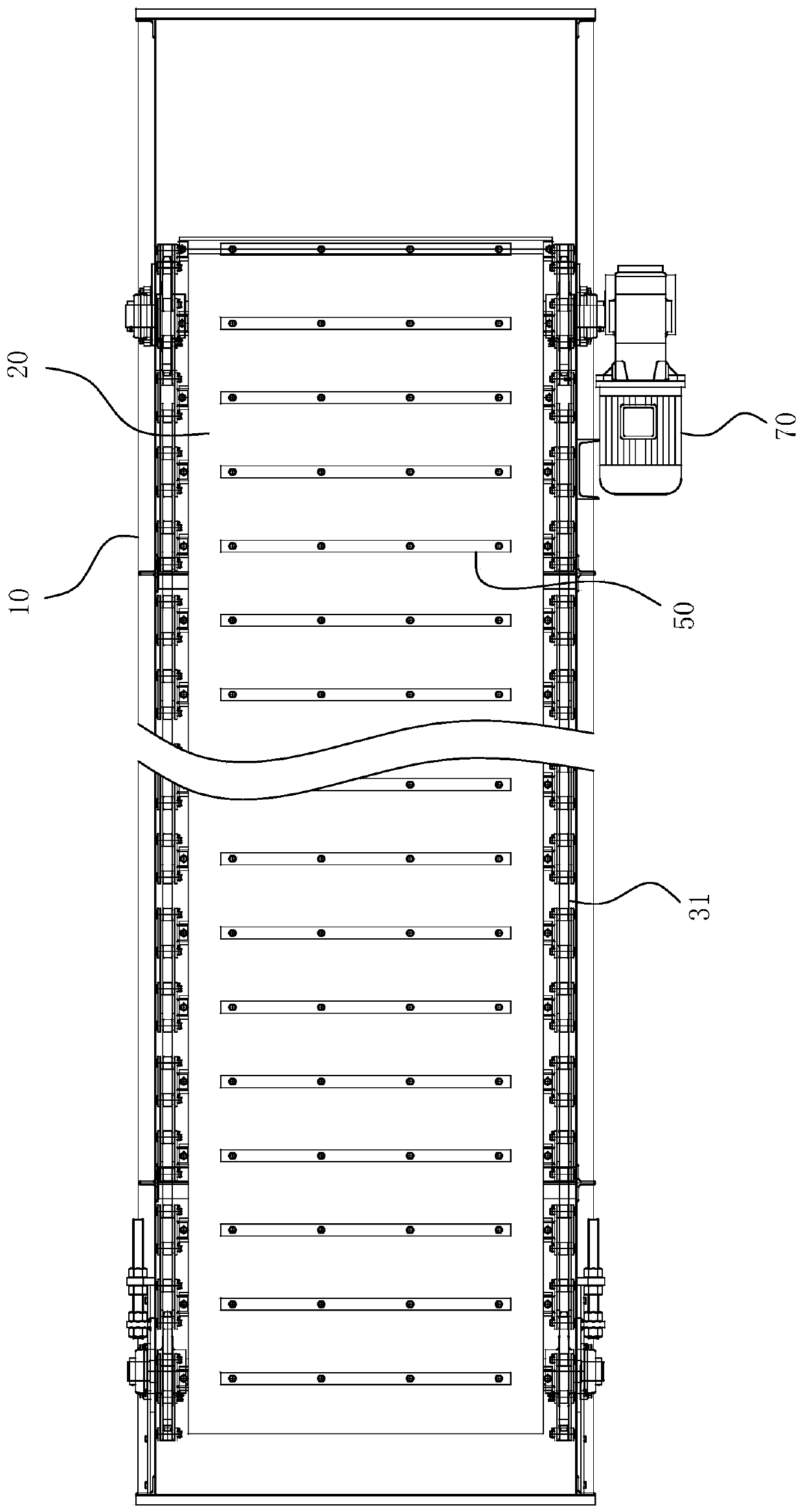

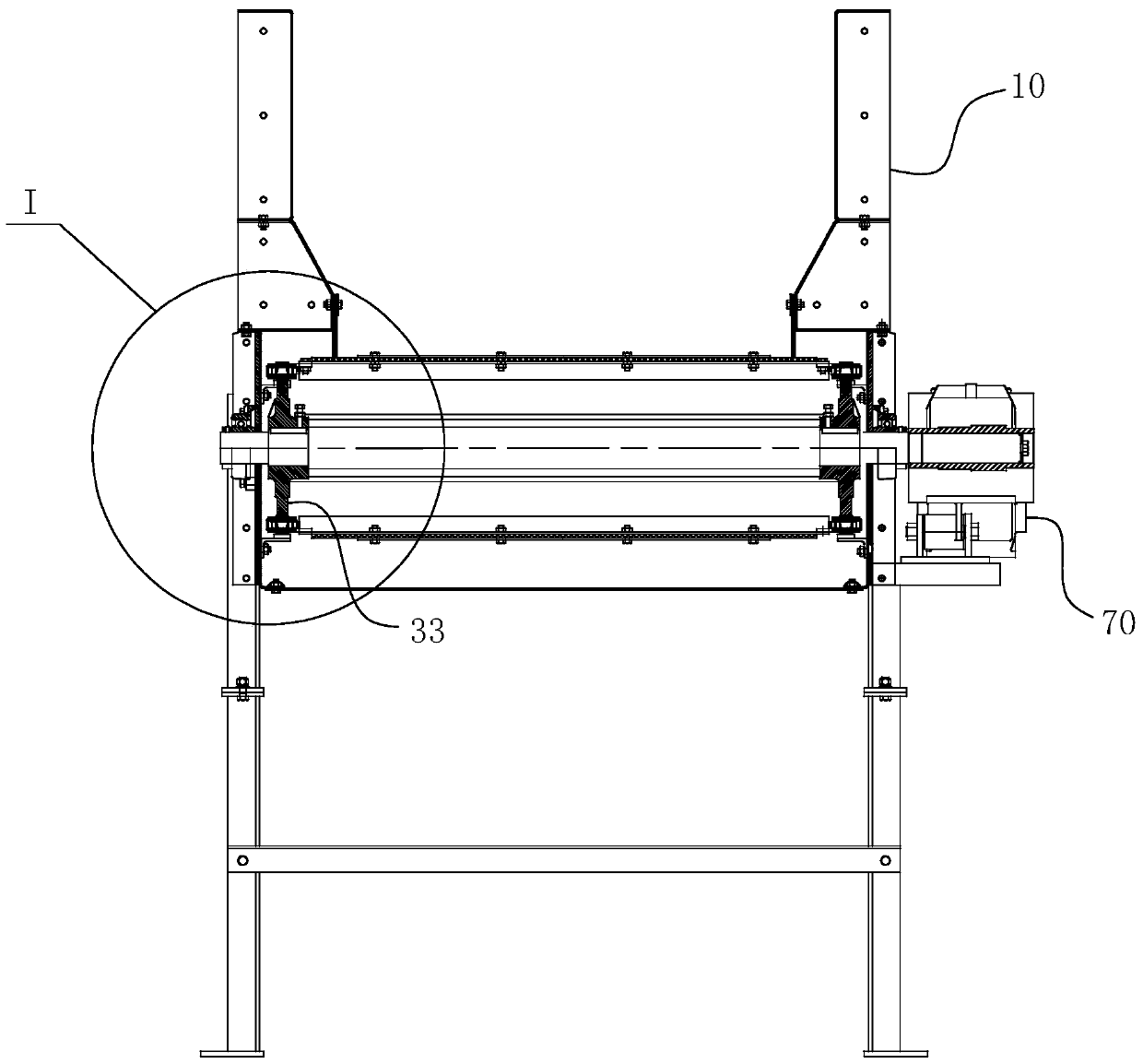

[0028] For ease of understanding, combined here Figure 1-5 The specific implementation structure and work flow of the present invention are described as follows:

[0029] The specific structure of the present invention is as Figure 1-5 As shown, it includes a chain conveyor fixed on the frame 10, and the chain plate 31 constituting the chain conveyor is fixed with a rubber pad 20, which constitutes the working surface of the entire conveyor. The belt rotates together with the chain plate 31 to convey the material.

[0030] Such as Figure 1-3 As shown, the device is driven by a geared motor with a hollow shaft structure, that is, the power part 70. The geared motor is fixed on the frame 10, and drives the driving toothed roller 33a to generate action through gear meshing. The driving toothed roller 33a rotates, and the toothed chain on it rotates thereupon to drive the chain 32, thereby making the complete machine run. For concretely realizing the conveyor belt structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com