Novel high-synchronism double-column lifting machine

A synchronous, lift technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems of lifting to one side, personnel injury, vehicle damage, etc., to improve rigidity and strength, increase load, and stable performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

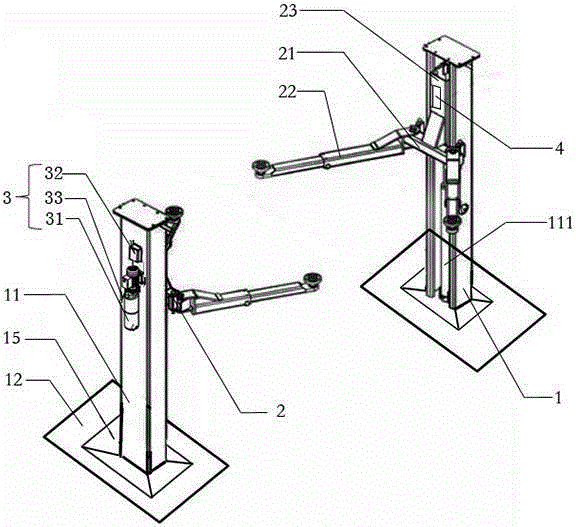

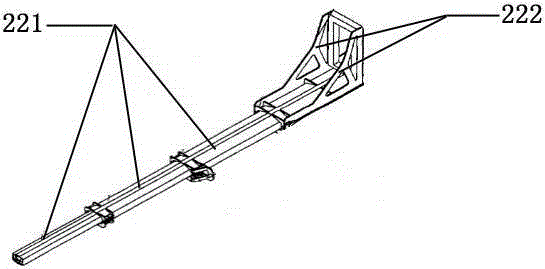

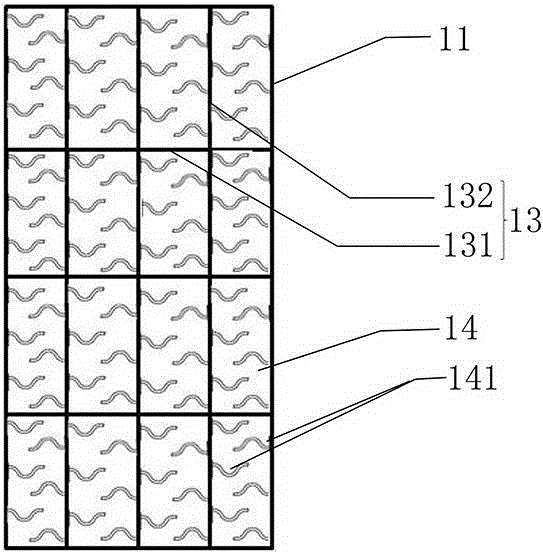

[0024] Such as figure 1 The shown high-synchronization novel double-column lift includes a supporting mechanism 1, a lifting mechanism 2 and a power mechanism 3, and also includes a synchronous positioning mechanism 4, wherein the synchronous positioning mechanism 4 includes a photoelectric sensor, and the photoelectric sensor is connected to the The intelligent control chip is electrically connected. In addition, the support mechanism 1 includes a column 11 and a base 12, the column 11 is vertically arranged on the base 12; On the other side of column 11. In addition, if image 3 As shown, the column 11 is provided with a set of support beams 13, the support beams 13 include a support beam 131 and a support longitudinal beam 132, and the column 11 is divided into a set of rectangular support tubes 14 with a cross section of "□". . Wherein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com