Novel horizontal type multilevel vortex pump

A swirl pump, horizontal technology, applied in the field of horizontal multi-stage pumps, can solve the problems of frequent replacement, failure to meet the use requirements, rapid wear of pump seal rings, guide vane sleeves, etc., to ensure no axial series movement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing of description and embodiment:

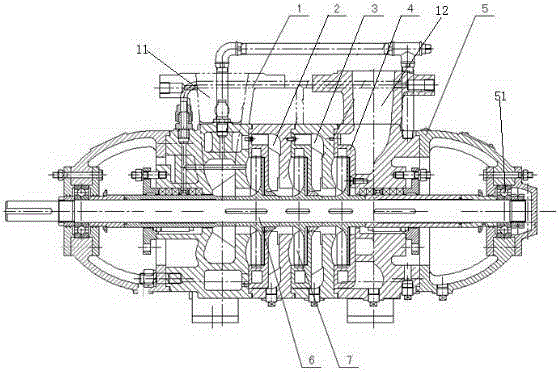

[0011] As shown in the figure, the novel horizontal multistage swirl pump includes a pump body 1, a rotor part 6 connected with three sets of swirl pump impellers 7, and two bearing bodies 5, and the two bearing bodies 5 are respectively connected to two ends of the pump body. end, the rotor part is rotatably installed in the pump body and the two ends of the rotor part are respectively connected with the bearing body; the outer side of the pump body is respectively provided with a water inlet 11 and a water outlet 12, and the middle part of the pump body is provided with interconnected The water inlet section chamber 2, the middle section chamber 3 and the water outlet section chamber 4, three sets of swirl pump impellers are respectively located in the water inlet section chamber, the middle section chamber and the water outlet section chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com